Abstract

It is shown that the earlier discovered features of the composition and properties of electrochemical coatings obtained by induced codeposition of alloys of iron-group metals (W, Mo, Re)—such as nanocrystallinity (X-ray amorphous phase), macroscopic size effects of microhardness and corrosion resistance, the effect of the volume current density on the properties and composition—are a consequence of the fractality of the solutions of relevant metal complexes (e.g., citrate and gluconate) in combination with the intensive interfacial exchange. In this case, the kinetics of nano-nucleation limits the size of growing nuclei of the alloy and, as a result, water molecules participate in the formation of coatings, leading to the incorporation of oxide-hydroxide inclusions into the solid phase and hydrogenation.

Similar content being viewed by others

REFERENCES

Eliaz, N. and Gileadi, E., Induced codeposition of tugsten, molibdenum and rhenium with transition metals, Mod. Aspects Electrochem., 2008, vol. 42, p. 191.

Tsyntsaru, N., Cesiulis, H., Donten, M., Sort, J., et al., Modern trends in tungsten alloys electrodeposition with iron-group metals, Surf. Eng. Appl. Electrochem., 2012, vol. 48, no. 6, p. 491.

Cesiulis, H., Tsyntsaru, N., Podlaha, E., Li, D., et al., Electrodeposition of iron-group alloys in to nanostructured oxide membranes: Synthetic challenges and properties, Curr. Nanosci., 2018, vol. 14, p. 1.

Brenner, A., Electrodeposition of Alloys. Principles and Practice, New York: Academic, 1963.

Krasikov, A.V. and Krasikov, V.L., Mechanism for induced codeposition of alloys and some single refractory metals, Izv. S.-Peterb. Gos. Tekhnol. Inst. (Tekh. Univ.), 2016, no. 37, p. 8. https://doi.org/10.15217/issn1998984-9.2016.37.8

Vas’ko, A.T., Elektokhimiya vol’frama (Electrochemistry of Tungsten), Kiev: Tekhnika, 1977.

Chassing, E., Quang, K., and Wiart, R., Mechanism of nickel–molibdenum alloy electrodeposition in citrate electrolytes, J. Appl. Electrochem., 1989, vol. 19, p. 839.

Podlaha, E.J. and Landolt, D., Induced codeposition. I. Experimental investigation of Ni–Mo alloys, J. Electrochem. Soc., 1996, vol. 143, p. 885.

Podlaha, E.J. and Landolt, D., Induced codeposition. II. Mathematic modeling of Ni–Mo alloys, J. Electrochem. Soc., 1996, vol. 143, p. 893.

Podlaha, E.J. and Landolt, D., Induced codeposition. III. Mathematic modeling of Ni–Mo alloys with nickel, cobalt and iron, J. Electrochem. Soc., 1997, vol. 144, p. 1672.

Sun, S. and Podlaha, E.J., Electrodeposition of Mo-rich MoNi alloys from an aqueous electrolyte, J. Electrochem. Soc., 2012, vol. 159, p. D1.

Younes, O., Zhu, L., Rosenderg, Y., et al., Electroplating of amorphous thin films of tungsten/nickel alloys, Langmiur, 2001, vol. 17, p. 8270.

Younes, O. and Gileadi, E., Electroplating of Ni–W alloys. I. Ammonium citrate baths, J. Electrochem. Soc., 2002, vol. 149, p. 100.

Younes, O., Metzler, O., Zhu, L., and Gileadi, E., Anomalous codeposition of tungsten in the presence of nickel, Electrochim. Acta, 2003, vol. 48, p. 2551.

Younes, O. and Gileadi, N., Electroplating of high tungsten content in Ni/W alloys, Electrochem. Solid-State Lett., 2000, vol. 3, p. 543.

Nicolenco, A., Tsyntsaru, N., and Cesiulis, H., Fe(III)-based ammonia-free bath for electrodeposition of Fe–W alloys, J. Electrochem. Soc., 2017, vol. 164, no. 9, p. D590.

Silkin, S.A., Gotelyak, A.V., Tsyntsaru, N., and Dikusar, A.I., Size effect of microhardness of nanocrystalline Co–W coatings produced from citrate and gluconate solutions, Surf. Eng. Appl. Electrochem., 2015, vol. 51, no. 3, p. 228.

Belevskii, S.S., Bobanova, Zh.I., Buravets, V.A., Gotelyak, A.V., et al., Electrodeposition of Co–W coatings from boron gluconate electrolyte with soluble tungsten anode, Russ. J. Appl. Chem., 2016, vol. 89, no. 4, p. 1427.

Gotelyak, A.V., Silkin, S.A., Yahova, E.A., and Dikusar, A.I., Effect of pH and volume current density on deposition rate and microhardness of Co–W coatings electrodeposited from concentrated boron-gluconate electrolyte, Russ. J. Appl. Chem., 2017, vol. 90, no. 4, p. 541.

Silkin, S.A., Gotelyak, A.V., Tsunysaru, N., and Dikusar, A.I., Electrodeposition of alloys of the iron group metals with tungsten from citrate and gluconate solutions: Size effect of microhardness, Surf. Eng. Appl. Electrochem., 2017, vol. 53, no. 1, p. 6.

Danilchuk, V.V., Silkin, S.A., Gotelyak, A.V., Buravets, V.A., et al., The microhardness properties andrate of electrodeposition of Co–W alloys from boro-gluconate bath: Impact of anodic processes, Russ. J. Electrochem., 2018, vol. 54, no. 11, p. 930.

Belevskii, S.S., Gotelyak, A.V., Silkin, S.A., and Dikusar, A.I., Macroscopic size effect of the microhardness of electroplated iron group metal–tungsten alloy coatings: Impact of electrode potential and oxygen-containing impurities, Surf. Eng. Appl. Electrochem., 2019, vol. 55, no. 1, p. 46.

Belevskii, S.S., Danilchuk, V.V., Gotelyak, A.V., Lelis, M., et al., Electrodeposition of Fe–W alloys from citrate bath: Impact of anode material, Surf. Eng. Appl. Electrochem., 2020, vol. 56, no. 1, p. 1.

Myrzak, V., Gotelyak, A.V., and Dikusar, A.I., Size effects in the surface properties of electroplated alloys between iron group metals and tungsten, Surf. Eng. Appl. Electrochem., 2021, vol. 57, no. 4, p. 1.

Belevskii, S.S., Kosova, A.P., Yushchenko, S.P., Yahova, E.A., et al., Changes in the properties of citrate electrolyte used to manufacturing cobalt–tungsten coatings, Surf. Eng. Appl. Electrochem., 2011, vol. 47, no. 1, p. 4.

Gamburg, Yu.D. and Zaharov, E.N., Electrodeposition of ternary Fe–W–H alloys, Surf. Eng. Appl. Electrochem., 2019, vol. 55, p. 402.

Belevskii, S.S., Yushchenko, S.P., and Dikusar, A.I., Anomalous electrodeposition of Co–W coatings from a citrate electrolyte due to the formation on a multinuclear heterometallic complexes in solutions, Surf. Eng. Appl. Electrochem., 2012, vol. 48, p. 97.

Belevskii, S.S., Buravets, V.A., Yushchenko, S.P., Zgardan, I.M., et al., Gel-chromatographic separation of boron-gluconate electrolyte for obtaining nano-crystalline Co–W coatings: Composition and electrochemical activity of components. Part I. Gel-chromatographic study of electrolyte, separation and composition of components, Surf. Eng. Appl. Electrochem., 2016, vol. 52, no. 4, p. 350.

Belevskii, S.S., Buravets, V.A., Yushchenko, S.P., and Dikusar, A.I., Part II. Electrochemical activity of separation products and their role in processes of manufacturing of alloy, Surf. Eng. Appl. Electrochem., 2016, vol. 52, no. 5, p. 420.

Gamburg, Yu.D. and Zangari, J., Theory and Practice of Metal Electrodeposition, New York: Springer-Verlag, 2011.

Gamburg, Yu.D. and Baranov, S.A., Typical clusters size in metal electrodeposition, Surf. Eng. Appl. Electrochem., 2020, vol. 56, no. 2, p. 147. https://doi.org/10.3103/S1068375520020076

Zel’dovich, Ya.B. and Sokolov, D.D., Fractals, similarity, intermediate asymptotics, Sov. Phys. Usp., 1985, vol. 28, p. 608. https://doi.org/10.1070/PU1985v028n07ABEH003873

Weston, D., Harris, S., Capel, H., Ahmed, N., Shipway, P., and Yellup, J., Nanostructured Co–W coatings produced by electrodeposition to replace hard Cr on aerospace components, Trans. Inst. Met. Finish., 2010, vol. 88, no. 1, p. 47.

Baranov, S.A., On the possibility of using the Cahn–Hilliard model to describe electrodeposition of nanostructures, Surf. Eng. Appl. Electrochem., 2017, vol. 53, no. 2, p. 124. https://doi.org/10.3103/S1068375517020028

Baranov, S.A., Modeling of micro- and nanocylinder, J. Anal. Tech. Res., 2021, vol. 3, no. 2, p. 28. https://doi.org/10.26502/jatri.020

Baranov, S.A., On the size dependence of the surface tension for micro- and nanocylinder, J. Anal. Tech. Res., 2021, vol. 3, no. 2, p. 39. https://doi.org/10.26502/jatri.021

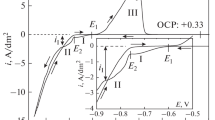

Belevskii, S., Silkin, S., Tsyntsaru, N., et al., Effect of sodium tungstate on electrode reactions at iron–tungstate alloy electrodeposition, Coatings, 2021, vol. 11, no. 8, pp. 981-1–981-14. https://doi.org/10.3390/coatings11080981

Nicolenco, A., Tsyntsaru, N., Fornell, J., et al., Mapping of magnetic and mechanical properties of Fe–W alloys electrodeposited from Fe(III)-based glycolate-citrate bath, Mater. Des., 2018, no. 139, p. 429.

Vetter, K.J., Elektrochemische kinetik, Berlin: Springer, 1961.

Isaev, V.A., Elektrokhimicheskoe fazoobrazovanie (Electrochemical Phase Formation), Yekaterinburg: Ural. Otd. Russ. Akad. Nauk, 2007.

Funding

This work was supported by the ANCD project (Moldova) no. 19.80013.50.07.06 А/BL “Manufacturing of New Micro- and Nanostructuring Materials by Physicochemical Methods and the Elaboration on Their Base” and partially funded by the European Project EU-H2020 MSCA–RISE Smartelectrodes (no. 778357) and supported by budget funding of the Shevchenko Pridnestrovie State University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Muravev

APPENDIX

APPENDIX

The problems associated with the introduction of the concept of Tolman parameter δ for the case of electrochemical nucleation were considered in detail in [31]. Because the Tolman parameter is a theoretical quantity (even though there is a thermodynamic definition of it that cannot be directly measured in experiment), this parameter can characterize different physical processes in the case of specific physical processes of nucleation. This parameter was introduced by Tolman to obtain the size dependence of the surface tension. In nanotechnologies, the Tolman parameter now determines the surface layer thickness of a nanoparticle (during its nucleation and growth).

Let us consider a case of electrochemical deposition. Let us provide for clarity a known qualitative scheme of the distribution of the surface potential in the near-surface layer of the cathode [39, 40]:

In considering the growth of a cylindrical nanoparticle, we can associate the Tolman parameter with the diffuse part of the double layer, for which the diffusion equation for the concentration of fragments forming a cylindrical nanoparticle, denoted as c, is valid. In the case of cylindrical symmetry, the equation is as follows [39, 40; Eqs. (2.391) and (1.45), respectively]:

(Concentration at the infinity is taken to be unity.) Eq. (A.1) is analogous to Eq. (2). Consequently, one can compare the λ value from Eq. (A.1) with the δ value from Eq. (2).

It should be noted that it is interesting to consider diffusion current based on the equation analogous to Eq. (6). However, this is beyond the scope of this work.

About this article

Cite this article

Baranov, S.A., Dikusar, A.I. Kinetics of Electrochemical Nanonucleation during Induced Codeposition of Iron-Group Metals with Refractory Metals (W, Mo, Re). Surf. Engin. Appl.Electrochem. 58, 429–439 (2022). https://doi.org/10.3103/S1068375522050027

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375522050027