Abstract

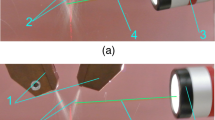

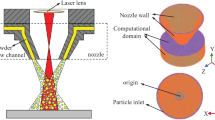

A production process of laser cladding using a coaxial supply layout of powder in the processing zone is investigated. Main attention is paid to investigating the joint influence of parameters of the focused gas—powder jet and focused laser radiation on the properties of the facing layer (sizes, porosity, etc.). The investigation was performed in two directions, notably: 1) numerical modeling (with experimental verification of the results) of focusing the gas—powder mixture by jets of various configurations and 2) modeling by the methods of experimental design. The results of numerical modeling were used when describing the cladding method by methods of experimental design. The data found from the active performance strategy of the investigations showed the statistically valuable influence of these parameters (mutual arrangement of the caustic constriction, shape of the gas—powder jet, treated surface, etc.) on the productivity (sizes) and quality (number of pores) in the facing track.

Similar content being viewed by others

References

LIA Handbook on Laser Materials Processing, Ready, J., Ed., Orlando, FL: LIA, Magnolia Publishing, 2001.

Xue, L., Theriault, A., Rubinger, B., Parry, D., Ranjbaran, F., and Doyon, M., Investigation of laser consolidation process for manufacturing structural components for advanced robotic mechatronics system (ARMS), in Proc. Int. Cong. “ICALEO’2003”, Jacksonville, USA, 2003, paper #909.

Pinkerton, A.J. and Lin Li, A verified model of the behaviour of the axial powder stream concentration from a coaxial laser cladding nozzle, in Proc. Int. Cong. “ICALEO’2002”, Scottsdale, USA, 2002.

Pinkerton A., Moat R., Shah K., Lin Li, Preuss M., and Withers P., A verified model of laser direct metal deposition using an analytical enthalpy balance method, in Proc. Int. Cong. “ICALEO’2007”, Orlando, USA, 2007, paper #1806.

Pinkerton, A.J. and Lin Li, Modelling powder concentration distribution from a coaxial deposition nozzle for laser-based rapid tooling, J. Manuf. Sci. Eng., 2004, vol. 126, pp. 33–41, doi: 10.1115/1.1643748

Kovalenko, V., Yao, J., Zhang, Q., Kondrashev, P., Anyakin, M., Zhuk, R., and Stepura, O., Influence of the interaction of focused laser beam and gas-powder stream on the quality of laser processing, Procedia CIRP, 2013, no. 6, pp. 498–503, doi: 10.1016/j.procir.2013.03.062

Ibarra-Medina, J., Vogel, M., and Pinkerton, A.J., A CFD model of laser cladding: from deposition head to melt pool dynamics, in Proc. 30th Int. Cong. on Application of Lasers and Electro-Optics (ICALEO), Orlando, USA, 2011.

Yao, J., Kovalenko, V.S., Zhang, Q., Anyakin, M., Hu, X., and Wang, W., Modeling of laser cladding with diode laser robotized system, Surf. Eng. Appl. Electrochem., 2010, vol. 46, no. 3, pp. 266–270.

ANSYS CFX-SolverTheory Guide, ANSYS CFX Release 11. 0, Ansys Inc.

Novik, F.S. and Arsov, Ya.B., Optimizatsiya protsessov tekhnologii metallov metodami planirovaniya eksperimentov (Optimization of Processes for Technology of Metals by Experiment Design Methods), Moscow: Nauka, 1980.

Himmelblau, D.M., Applied Nonlinear Programming, New York: McGraw-Hill, 1972.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Q. Zhang, J. Yao, V.S. Kovalenko, X. Hu, N.I. Anyakin, P.V. Kondrashev, R.O. Zhuk, A.N. Stepura, 2015, published in Elektronnaya Obrabotka Materialov, 2015, No. 4, pp. 34–41.

About this article

Cite this article

Zhang, Q., Yao, J., Kovalenko, V.S. et al. Productivity and quality of cladding with a coaxial supply of laser radiation and a gas—powder mixture (Jet). Surf. Engin. Appl.Electrochem. 51, 339–346 (2015). https://doi.org/10.3103/S1068375515040158

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375515040158