Abstract

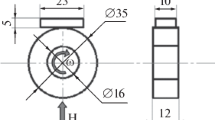

Investigations presented in this paper were carried out using an originally designed rotary piezoelectric motor of a standing wave tribotester. Test conditions, such as the normal force value in the friction pair, the rotor stop torque value, and the test duration can be programmed and changed in a desirable mode. The rotation speed, covered distance and loading torque of a piezo actuator were measured. Two different coatings (WC-Co8 and TiC15-Co6) were tested as the rotor friction surface and the wear of friction pairs (rotor, counter body) was evaluated after the tests. Investigations reveal an incidental advantage of output parameters of the piezo actuator with the TiC15-Co6 coating on the friction pair. Besides, high hardness of carbide surfaces requires paying more attention to the wear resistance of the frictional material of the counter body.

Similar content being viewed by others

References

Wallaschek, J., Contact mechanics of piezoelectric ultrasonic motors, Smart Mater. Struct., 1998, vol. 7, no. 3, pp. 369–381.

Padgurskas, J., Kurtinaitis, A., Žunda, A., Rukuiža, R., Andriušis, A., Bubulis, A., and Jankauskas, V., Tribological evaluation of nano-composite coatings in piezoelectric contact, J. Vibroeng., 2012, vol. 14, no. 4, pp. 1801–1806.

Claeyssen, F., Belly, C., Le Letty, R., and Bagot, M., Dynamic strain limits of amplified piezo actuators, Proceedings 12th International Conference on New Actuators and 6th International Exibition on Smart Actuators and Drive Systems, Bremen, Germany, 2010, pp. 141–144.

Kuo, W.M., Chuang, S.F., Nian, C.Y., and Tarng, Y.S., Precision nano-alignment system using machine vision with motion controlled by piezoelectric motor, Mechatronics, 2008, vol. 18, pp. 21–34.

Wang, Z.L., Progress in piezotronics and piezo-phototronics, Adv. Mater., 2012, vol. 24, pp. 4632–4646.

Padgurskas, J., Bansevičius, R., Žunda, A., Rukuiža, R., and Andriušis, A., Investigation of tribological properties in piezoelectric contact, Surf. Eng. Appl. Electrochem., 2013, vol. 49, no. 5, pp. 401–407.

Padgurskas, J., Zunda, A., Andriusis, A., Metrikaite, D., Jankauskas, V., Rukuiza, R., and Bansevicius, R., The effect of fluorine oligomer coatings on the tribocontacts of a piezoelectric actuator, J. Friction Wear, 2014, vol. 35, no. 1, pp. 1–6.

Ko Hyun-Phill, Kim Sangsig, Kim Jin-Sang, Kim Hyun-Jai, and Yoon Seok-Jin, Wear and dynamic properties of piezoelectric ultrasonic motor with frictional materials coated stator, Mater. Chem. Phys., 2005, vol. 90, pp. 391–395.

Olofsson, J., Lindberg, F., Johansson, S., and Jacobson, S., On the role of tribofilm formation on the alumina drive components of an ultrasonic motor, Wear, 2009, vol. 267, pp. 1295–1300.

Spaltman, D., Hartelt, M., and Woydt, M., Triboactive materials for dry reciprocating sliding motin at ultrahigh frequency, Wear, 2009, vol. 266, pp. 167–174.

Gitlevich A.E., Mihailov, V.V., Parkanskij, N.Ya., and Revutskiy, V.M., Electrospark Alloying of Metallic Surfaces, Chisinau: Stiinta, 1985, 198 p. (in Russian).

Kovalenko, S.V., Nikolenko, S.V, Verchoturov, A.D., and Kutsenko, V.S., Investigation of impact of mechanical parameters of automate electrospark alloying devise with turning electrode on the surface layer formation, Elektron. Obrab. Mater., 2003, no. 3, 14–21.

Verchoturov, A.D., Podchernyayeva I.A., and Konevtsov, L.A., Electrospark depositing of metallic and ZrB2 based ceramic coatings on tungstenferous hard alloys for the efficiency improvement, Elektron. Obrab. Mater., 2007, no. 6, 10–19.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Padgurskas, J., Žunda, A., Rukuiža, R. et al. Investigation of tribological properties of carbide coatings deposited by electrospark at piezoelectric tribocontact. Surf. Engin. Appl.Electrochem. 51, 125–132 (2015). https://doi.org/10.3103/S1068375515020106

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375515020106