Abstract

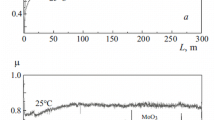

The results of a study of the friction and wear characteristics of the developed nanostructured glass-composite self-lubricating detonation coatings with the composition SiC–Ni–Cu–Al–Si–C additionally containing a SiO2–Al2O3–B2O3 aluminoborosilicate glass phase and structurally free MgC2, which forms α‑graphite during thermal decomposition are presented. It is indicated that their synergistic effect promotes the creation of an antifriction surface layer that minimizes contact parameters. An increase in the adhesion strength of the coatings is achieved by preliminarily applying a sublayer of glass-like sodium silicate Na2O(SiO2)2 onto the working surface. It is noted that the intercalation of the graphite layer by the particles of the subsurface zone does not affect the tribotechnical characteristics of the coatings. The developed coatings show high performance properties; here, the way of wear stabilization is the presence of a thin-film antifriction layer based on α-graphite, which shields unacceptable processes of molecular adhesion interaction.

Similar content being viewed by others

REFERENCES

Makhesana Mayur, A. and Patel, K.M., Performance assessment of CaF2 solid lubricant assisted minimum quantity lubrication in turning, Proc. Manuf., 2019, no. 33, pp. 43–50. https://doi.org/10.1016/j.promfg.2019.04.007

Justin, A.I. and Lenin, S.D., Tribological characterization of various solid lubricants based copper-free brake friction materials—a comprehensive study, Mater. Today, 2020, vol. 27, no. 3, pp. 2650–2656. https://doi.org/10.1016/j.matpr.2019.11.088

Antsupov, A.V., Fedulov, A.A., Antsupov, A.V., and Antsupov, V.P., An application of antifriction coatings to increase the lifetime of friction units, Mech. Eng. MATEC Web of Conf., 2021, vol. 346, p. 03024.

Matuszewski, M., Slomion, M., Mazurkiewicz, A., and Wojciechowski, A., Mass wear application of cooperated elements for evaluation of friction pair components condition, Mech. Eng. MATEC Web of Conf., 2021, vol. 351, p. 01006. https://doi.org/10.1051/matecconf/202135101006

Babak, V.P., Shchepetov, V.V., and Nedaiborshch, S.D., Wear resistance of nanocomposite coatings with dry lubricant under vacuum, Nauk. Visn. Nats. Hirnych. Univ., 2016, no. 1. nbuv.gov.ua/UJRN/Nvngu_ 2016_1_9

Babak, V.P., Shchepetov, V.V., and Kharchenko, S.D., Antifriction nanocomposite coatings that contain magnesium carbide, J. Frict. Wear, 2019, no. 6, pp. 593–598. https://doi.org/10.3103/S1068366619060035

Vilhena, L., Ferreira, F., Oliveira, J.C., and Ramalho, A., Rapid and easy assessment of friction and load-bearing capacity in thin coatings, Electronics, 2022, no. 11, p. 296. https://doi.org/10.3390/electronics11030296

Zaytsev, A.N., Aleksandrova, Y.P., and Yagopolskiy, A.G., Comparative analysis of methods for assessing adhesion strength of thermal spray coatings, BMSTU J. Mech. Eng., 2021, no. 5 (734), pp. 48–59. https://doi.org/10.18698/0536-1044-2021-5-48-59

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Boltukhina

About this article

Cite this article

Babak, V.P., Shchepetov, V.V. & Kharchenko, S.D. Antifriction Nanostructural Glass-Composite Self-Lubricating Coatings. J. Frict. Wear 43, 215–220 (2022). https://doi.org/10.3103/S1068366622030023

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366622030023