Abstract

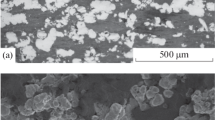

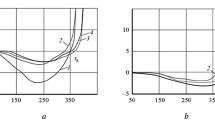

A metal–polymer composite material (MPCM) was obtained by explosive compaction. The structure of the MPCM is considered and its good electrical conductivity is established. Thorough tribological testing, depending on the load on the contact friction and sliding speed was carried out. The results of the tribological tests are compared with those for pure polytetrafluoroethylene. The possibility of using a copper–PTFE metal–polymer material as a tribotechnical material under conditions of dry friction and for sliding contacts with the self-lubrication effect has been shown.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Innovative developments of the All-Russian Scientific Research Institute of Aviation Materials within the project “Strategic development of materials and technologies of their recycling until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33.

Kablov, E.N., New generation materials as a basis for innovations, technological advantage, and national safety of Russia, Intell. Tekhnol., 2016, no. 2 (14), pp. 16–21.

Buznik, V.M. and Kablov, E.N., Arctic materials science: current state and prospects, Herald Russ. Acad. Sci., 2017, vol. 87, no. 5, pp. 397–408.

Farafonov, D.P., Migunov, V.P., and Alehsina, R.Sh., Tribotechnical characteristics of materials used for hardening of retaining shelves of gas-turbine engine blades, Aviats. Mater. Tekhnol., 2016, suppl. 1, pp. 24–30.

Kulagina, G.S., Korobova, A.V., Zuev, S.V., and Zhelezina, G.F., Tribological properties of organoplastics based on woven reinforcing filler, Tr. Vseross. Inst. Aviats. Mater., 2016, vol. 47, no. 11, pp. 47–55.

Solomentseva, A.V., Fadeeva, V.M., and Zhelezina, G.F., Antifriction organoplastics for heavily loaded sliding friction units of aircraft constructions, Aviats. Mater. Tekhnol., 2016, no. 2 (41), pp. 30–34.

Kovtun, V.A. and Pleskachevskii, Yu.M., Tribotechnicheskie pokrytiya na osnove poroshkovykh mednografitovykh sistem (Tribological Coatings Based on Copper-Graphite Powders), Vityaz’, P.A., Ed., Gomel: Inst. Mekh. Metallopolim. Sist., Nats. Akad. Nauk Bel., 1998.

Adamenko, N.A., Fetisov, A.V., and Agafonova, G.V., Explosion treatment of polymers and metal-polymer compositions, Polim. Mater., 2006, no. 12, pp. 26–29.

Rodionov, Yu.V. and Loginov, O.N., Schemes of explosive pressing in production of materials of automobile sensors, Alleya Nauki, 2018, no. 4, p. 20.

Baskin, Z.L., Shabalin, D.A., Vyrazheikin, E.S., and Dedov, S.A., Product range, properties, and application of fluoropolymers manufactured in Kirovo-Chepetsk Chemical Industrial Complex, Russ. J. Gen. Chem., 2009, vol. 79, no. 3, pp. 527–538.

Adamenko, N.A., Trykov, Yu.P., Fetsov, A.V., and Sedov, E.V., Shock-wave treatment of dispersed fluoroplast-4, Materialovedenie, 2000, no. 2, pp. 49–52.

Osintsev, O.E. and Fedorov, V.N., Med’ i mednye splavy. Otechestvennye i zarubezhnye marki: Spravochnik (Cooper and Cooper Alloys. National and Foreign Grades: Handbook), Moscow: Mashinostroenie, 2004.

Ostrovskii, V.S., Virgil’ev, Yu.S., Kostikov, V.I., and Shipkov, N.N., Iskusstvennyi grafit (Artificial Graphite), Moscow: Metallurgiya, 1986.

Petrova, L.G., Potapova, M.A., and Chudinova, O.V., Elektrotekhnicheskie materially: Uchebnoe posobie (Electrical Engineering Materials: Manual), Moscow: Mosk. Avtom. Dorozhn. Inst., 2008.

Seleznev, A.N., Uglerodistoe syr’e dlya elektrodnoi promyshlennosti (Carbon Materials for Electrode Industry), Moscow: Profizdat, 2000.

Sutyagin, V.M., Kukurina, O.S., and Bondaletov, V.G., Osnovnye svoistva polimerov: uchebnoe posobie (General Properties of Polymers: Manual), Tomsk: Tomsk. Politekh. Univ., 2010.

Gul’, V.E. and Shenfil’, L.Z., Elektroprovodyashchie polimernye kompozitsii (Electrical Conductive Polymeric Compositions), Moscow: Khimiya, 1984.

Funding

This work was carried out within the no. 12 Metal-matrix and polymatrix composite materials complex research direction [1].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Muravev

About this article

Cite this article

Sevostyanov, N.V., Rosen, A.E., Buznik, V.M. et al. A Copper–Fluoroplastic Composite Material Obtained by Explosive Pressing. J. Frict. Wear 41, 40–45 (2020). https://doi.org/10.3103/S1068366620010158

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620010158