Abstract

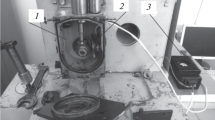

This paper presents the results of a study of the operation of a “roller—pad” friction pair under the influence of ultrasonic vibrations with a frequency of 8–17 kHz on lubricating oil. Further, the surface tension coefficient and the lubricating oil temperature during its processing in the frequency range of 8–43 kHz is evaluated. It has been established that both ultrasonic treatment of lubricating oil and the increase in the frequency of the treatment significantly improve the operating conditions of the friction pair, reducing the linear wear of samples, the rates of the wear of moving and fixed samples of friction pairs and the wear factor number. It has been established that the surface tension coefficient of synthetic motor oil, decreasing to the minimum value during the first 120 h of ultrasonic treatment, is maintained at this level for more than 72 h.

Similar content being viewed by others

REFERENCES

Kartoshkin, A.P., Ashkinazi, L.A., and Braslavskii, M.I., RF Patent 2 055 863, 1996.

Khmelev, V.N., et al., Ultrasonic cavitation treatment of viscous and dispersed liquid media, Polzunovskii Vestn., 2014, vol. 2, no. 4, pp. 110–115.

Verkhovykh, A.A., et al., Review of research works on the effect of ultrasound on petroleum systems, Vestn. Kazan.Tekhnol. Univ., 2016, vol. 19, no. 8, pp. 37–42.

Kargin, B.S., et al., Effect of ultrasonic fluctuations on efficiency of technological lubricants, Visn. Priazov. Derzh. Tekh. Univ., Tekh. Nauki, 2015, no. 30-1, pp. 136–140.

Efremov, L.V., Baeva, L.S., and Tikalov, A.V., Vibroacoustic testing of tribological joints on wear resistance, Vestn. Astrakh. Gos. Tekh. Univ., Ser.: Morsk. Tekh. Tekhnol., 2017, no. 2, pp. 69–79.

Simdyankin A.A., et al., Ultrasonic machining of engine lubricating oil during tribotechnical testing, J. Frict. Wear, 2017, vol. 38, no. 4, pp. 311–315.

Simdiankin A.A., et al., Effect of ultrasonic treatment of motor oil on wear of friction pairs in prolonged wear tests, Vestn. Mordovsk. Univ., 2018, vol. 28, no. 4, pp. 584–602.

ACKNOWLEDGMENTS

The article is based on the proceedings of the POLIKOMTRIB-2019 Conference held in Gomel, Belarus on June 25–28, 2019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Lotova

About this article

Cite this article

Simdiankin, A.A., Uspensky, I.A., Byshov, N.V. et al. The Effect of Ultrasonic Treatment of a Lubricating Oil on the Operation of a Tribological Assembly and the Assessment of the Residual Effects in the Oil. J. Frict. Wear 40, 461–467 (2019). https://doi.org/10.3103/S1068366619050167

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366619050167