Abstract

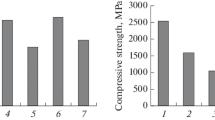

The effect of iron content on the strength and tribological characteristics of sintered tin-iron bronzes has been studied. It has been shown that the porosity has been reduced and the hardness monotonically increased with an increase in the iron content of the material. The strength dependence of the iron content is nonmonotonic, and the maximum strength increase took place at the iron content of 5%. The minimum coefficient of friction, the temperature in the friction zone and wear rate have been observed at iron content of 5–10%. In this case, the micropores and microlacunes have been formed on the friction surfaces that provide better lubricate conditions for the friction surfaces.

Similar content being viewed by others

References

Vetterick, G.A., Novel Lead-Free, Bronze Bearing Materials Produced by Powder Metallurgy Processing, Ames: Iowa State Univ., 2010.

Liang, S., Fang, L., Xu, L., and Fan, Z., Effect of Al content on the properties and microstructure of Al2O3–Cu composite prepared by internal oxidation, Acta Metall. Sin., 1999, vol. 35, pp. 888–892.

Korosteleva, E.N., Savitskii, A.P., and Rusin, N.M., Effect of FeAl3 additive and graphite on tribotechnical properties of sintered aluminum bronze, Perspekt. Mater., 1999, no. 4, pp. 58–61

Tu, J.P., Meng, L., and Liu, M.S., Friction and wear behavior of Cu–Fe3Al powder metallurgical composites in dry sliding, Wear, 1998, vol. 220, no. 1, pp. 72–79.

Konieczny, M, Laminar copper-intermetallics composite—generation and properties, Compos. Theory Pract., 2006, vol. 6, no. 4, pp. 52–55.

Çelikyürek, I., Körpe, N.Ö., Ölçer, T., and Galer, R., Microstructure, properties and wear behaviors of (Ni3Al)p reinforced Cu matrix composites, J. Mater. Sci. Technol., 2011, vol. 27, no. 10, pp. 937–943.

Krolczyk, G.M, Maruda, R.W., Nieslony, P., and Wieczorowski, M., Surface morphology analysis of Duplex Stainless Steel (DSS) in clean production using the power spectral density, Measurement, 2016, vol. 94, pp. 464–470.

Maruda, R.W., Legutko, S., Krolczyk, G.M., Lukianowicz, C., and Stoic, A., Effect of anti-wear additive on cutting tool and surface layer of workpiece state under MQCL conditions, Tehn. Vjestn., 2015, vol. 22, no. 5, pp. 1219–1223.

Ugarteche, C.V., Furlan, K.P., Vale Pereira, R., Trindade, G., Binder, R., Binder, C., and Klein, A.N., Effect of microstructure on the thermal properties of sintered iron-copper composites, Mater. Res., 2015, vol. 18, no. 6, pp. 1176–1182.

Biselli, C. and Morris, D.G., Microstructure and strength of Cu-Fe in situ composites obtained from prealloyed Cu–Fe powders, Acta Metall. Mater., 1994, vol. 42, no 1, pp. 163–176.

Sauvage, X., Wetscher, F., and Pareige, P., Mechanical alloying of Cu and Fe induced by severe plastic deformation of a Cu–Fe composite, Acta Mater., 2005, vol. 53, no. 7, pp. 2127–2135.

Dong, Q., Wang, M., Shen, L., Jia, Y., and Li, Z., Diffraction analysis of a-Fe precipitates in a polycrystalline Cu–Fe alloy, Mater. Charact., 2015, vol. 105, pp. 129–135.

Verma, H.C., Mössbauer studies of CuFe–72% alloy, Indian J. Pure Appl. Phys., 2007, vol. 45, no. 10, pp. 851–855.

Bizjak, M., Kosec, L., Kosec, B., and Anžel, I., The characterization of phase transformations in rapidly solidified Al–Fe and Cu–Fe alloys through measurements of the electrical resistance and DSC, Metalurgija, 2006, vol. 45, no. 4, pp. 281–286.

Dyachkova, L.N., Feldshtein, E.E., and Vityaz’, P.A., Tribological behavior of sintered tin bronze with additions of alumina and nickel oxide, J. Frict. Wear, 2013, vol. 34, no. 1, pp. 19–26.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.N. Dyachkova, E.E. Feldshtein, P.A. Vityaz, B.M. Błoch, L.Ya. Varanetskaya, 2018, published in Trenie i Iznos, 2018, Vol. 39, No. 3, pp. 221–226.

The article was translated by the authors.

About this article

Cite this article

Dyachkova, L.N., Feldshtein, E.E., Vityaz, P.A. et al. On the Effect the Iron Content on the Tribological Properties of Sintered Tin-iron Bronze. J. Frict. Wear 39, 173–178 (2018). https://doi.org/10.3103/S1068366618030030

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366618030030