Abstract

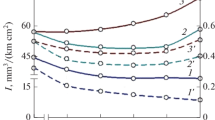

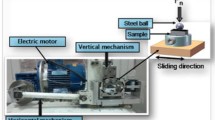

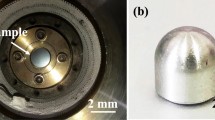

Specific features of the wear of an iron—graphite material with molybdenum disulfide additive produced by compaction followed by sintering or infiltration with tin bronze are studied. It has been found that in the course of friction the lubricant and hard wear particles accumulate in pores on the surface of the sintered material, which leads to the abrasive wear of the counterbody. During the friction of the infiltrated materials, selective mass transfer occurs due to the morphology of the copper phase, and the wear surfaces of these materials have a sponge—capillary structure. The wear resistance of the infiltrated materials is 2.5–3.3 times higher than that of the sintered materials.

Similar content being viewed by others

References

Zozulya, V.D., Ekspluatatsionnye svoistva poroshkovykh podshipnikov (Exploitation Properties of Powder Bearings), Kiev: Naukova Dumka, 1989.

Semenov, A.P., Antifriction materials: Application and outlook, Trenie Smazka Mash. Mekhan., 2007, no. 12, pp. 211–236.

James, W.B. and West, G.T., Ferrous powder metallurgy materials, Powder Metal Technologies and Applications of ASM Handbook. ASM Int., 1998, vol. 7, pp. 1872–1947.

Garkunov, D.R., Tribotekhnika (iznos i bezyznosnost') (Tribotecnics (Wear and Wearlessness), Moscow: MSKhA, 2001.

Myshkin, N.K., Friction transfer film formation in boundary lubrication, Wear, 2000, vol. 245, pp. 116–124.

Padgurskas, J., Snitka, V., Jankauskas, V., and Andriusis, A., Selective transfer phenomenon in lubricated sliding surfaces with copper and its alloy coatings made by electro-pulse spraying, Wear, 2006, vol. 260, pp. 652–661.

Ilie, F., Studies and researches concerning the tribological behavior of friction couple functioning with selective transfer, Tribol. Int., 2006, vol. 39, pp. 774–780.

Lubimov, D. and Dolgopolov, K., Micromechanisms controlling the structural evolution of tribosystems, in Nanocomposites with Unique Properties and Applications in Medicine and Industry, 2011.

Kuzharov, A.S., Bulgarevich, S.B., Burlakova, V.E., Kuzharov, A.A., and Akimova, E.E., Molecular mechanisms of self-organization at friction. Part vii. Fluctuations of the tribo-EMF and stepwise coagulation of copper nanoclusters when the servovit film appears under the effect of wearlessness, J. Frict. Wear, 2009, vol. 30, pp. 271–276.

Pinchuk, L.S. and Goldade, V.A., Smart materials in materials science, J. of Siber. Feder. Univ. Eng. Technol., 2013, no. 6, pp. 805–817.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.N. Dyachkova, E.E. Feldshtein, 2015, published in Trenie i Iznos, 2015, Vol. 36, No. 5, pp. 518–523.

About this article

Cite this article

Dyachkova, L.N., Feldshtein, E.E. Morphology of worn surfaces of iron–graphite materials sintered or infiltrated with tin bronze. J. Frict. Wear 36, 395–399 (2015). https://doi.org/10.3103/S1068366615050037

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366615050037