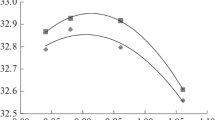

Abstract—The gross calorific value of wet-quenched blast-furnace coke fluctuates significantly as a function of the piece size. It is greatest for the <25 mm size class: 33.0 MJ/kg or more. The degree of conditioning of the coke, assessed in terms of the volatile matter and its actual density, has considerable influence on the gross calorific value. The less conditioned blast-furnace coke obtained from coke-battery 1 at MK Azovstal is characterized by higher gross calorific value of its size classes. The gross calorific value of blast-furnace coke provides another measure of its conditioning (its readiness for use).

Similar content being viewed by others

REFERENCES

Miroshnichenko, I.V., Miroshnichenko, D.V., Shulga, I.V., Balaeva, Y.S., and Pereima, V.V., Calorific value of coke. 1. Prediction, Coke Chem., 2019, vol. 62, no. 4, pp. 143–149.

Miroshnichenko, I.V., Miroshnichenko, D.V., Shulga, I.V., Balaeva, Y.S., and Pereima, V.V., Calorific value of coke. 2. Effect of bulk density of coal blend, Coke Chem., 2019, vol. 62, no. 6, pp. 234–239.

Miroshnichenko, I.V., Miroshnichenko, D.V., Shulga, I.V., Balaeva, Y.S., and Pereima, V.V., Calorific value of coke. 3. Impact of coal storage periods, Coke Chem., 2019, vol. 62, no. 12, pp. 556–564.

Ivanov, E.B. and Muchnik, D.A., Tekhnologiya proizvodstva koksa (Production Technology of Coke), Kiev: Vishcha Shkola, 1976.

Vol’fovskii, A.G., Mironenko, L.I., and Kaufman, A.A., Gazovshchik koksovykh pechei (Coke-Oven Heater), Moscow: Metallurgiya, 1989.

Sheptovitskii, M.S., Vol’fovskii, A.G., Shulga, I.V., et al., Thermal regime of extreme and mass heating channels of a coke oven battery no. 1-bis of the Mariupol Coke and Chemical Plant, Koks Khim., 1992, no. 6, pp. 19–22.

Tregubov, D.G. and Miroshnichenko, D.V., Theory and practice of reduction of coke sulfur: A review, Koks Khim., 2005, no. 6, pp. 21–28.

Pudak, A.I., Litvinov, O.N., Oleinikov, V.V., et al., Coking in a coke oven battery no. 1-bis of the Mariupol Coke and Chemical Plant, Koks Khim., 1991, no. 9, pp. 15–19.

Sytnik, A.V., Kuznichenko, V.M., and Shulga, I.V., Comparison of the expansion pressure of loose and rammed coal charge, Coke Chem., 2012, vol. 55, no. 2, pp. 50–55.

Sytnik, A.V., Kuznichenko, V.M., and Miroshnichenko, D.V., Expansion pressure of coal with diff erent genetic and technological properties, Coke Chem., 2011, vol. 54, no. 1, pp. 1–3.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Miroshnichenko, I.V., Miroshnichenko, D.V., Shulga, I.V. et al. Calorific Value of Coke. 4. Size Distribution. Coke Chem. 63, 120–125 (2020). https://doi.org/10.3103/S1068364X20030059

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X20030059