Abstract

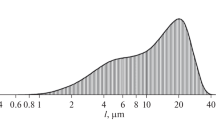

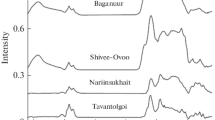

The behavior of coal tars with different levels of pyrolysis in thermal fractionation is compared in the laboratory. The properties and group composition of the nonboiling residues (medium-temperature pitch) obtained by the distillation of coal tars at different temperatures, in comparable conditions, is investigated. The results indicate that the distillation of tars characterized by slight pyrolysis is accompanied by vigorous destruction processes, also affecting the α1 fraction (t = 335–350°C), with subsequent reactions among the destruction products, leading to active increase in the α1 and α2 fractions (t ≥ 350°C). This is a significant difference between tars characterized by light pyrolysis and considerable pyrolysis.

Similar content being viewed by others

References

Skripchenko, N.P., Cheshko, F.F., Bannikov, L.P., and Rudkevich, M.I., Production of impregnating pitch without coal-tar purification, Uglekhim. Zh., 2010, no. 5/6, pp. 55–59.

Skripchenko, N.P., Cheshko, F.F., and Bannikov, L.P., Production of high-quality impregnating pitch in Ukraine, Strategiya kachestva v promyshlennosti i obrazovanii (Conference on Quality Strategies in Industry and Education), Varna, 2010, pp. 392–394.

Tarasyuk, Yu.Ya., Serik, D.T., Bukka, A.A., et al., Improving the production of coal pitch from blends of different manufacturers’ coal tars, Uglekhim. Zh., 2010, no. 5/6, pp. 59–63.

Cheshko, F.F. and Rudkevich, M.I., Thermal processing of coal-tar components, Postup v naftogazoperebornii ta naftokhimichii promislovosti: zb. tez. dopovidei VI Naukovo-tekhn. konf. (Oil and Gas Processing in the Petrochemical Industry: Abstracts of Proceedings of the Sixth Conference), L’viv: Vidavnitstvo L’vivs’koi Politekhniki, 2012.

Skripchenko, M.P., Aspects of the Processing of Coal Pitch, Extended Abstract of Cand. Sci. Dissertation, Kharkov, 2006.

Kovalev, E.T., Pityulin, I.N., and Cheshko, F.F., Spravochnik koksokhimika. T. 3. Ulavlivanie i pererabotka khimicheskikh produktov koksovaniya (Handbook of Coke Chemistry, Vol. 3: Capture and Processing of Coking Byproducts), Kharkov: ID INZHEK, 2009, chap. 14.

Pityulin, I.N., Nauchno-tekhnologicheskie osnovy sozdaniya kamennougol’nykh uglerodsoderzhashchikh materialov dlya krupnogabaritnykh elektrodov (Principles Adopted in Creating Coal-Based Carbon Materials for Large Electrodes), Kharkov: IPTs Kontrast, 2004.

Chistyakov, A.N., Khimiya i tekhnologiya pererabotki kamennougol’nykh smol (Chemistry and Technology of Coal-Tar Processing), Chelyabinsk: Metallurgiya, Chelyabinsk. Otd., 1990.

Gogoleva, T.Ya. and Shustikov, V.I., Khimiya i tekhnologiya pererabotki kamennougol’noi smoly (Chemistry and Technology of Coal-Tar Processing), Moscow: Metallurgiya, 1992.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © F.F. Cheshko, N.P. Skripchenko, L.P. Bannikov, V.V. Karchakova, E.E. Prokhach, 2014, published in Koks i Khimiya, 2014, No. 6, pp. 34–38.

About this article

Cite this article

Cheshko, F.F., Skripchenko, N.P., Bannikov, L.P. et al. Properties of coal tar characterized by slight pyrolysis. Coke Chem. 57, 255–259 (2014). https://doi.org/10.3103/S1068364X14060027

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X14060027