Abstract

The results of a study of the features of the dissolution processes of metallic platinum, rhodium, and iridium in hydrochloric acid solutions under hydrothermal autoclave conditions are presented. Hydrogen peroxide is used as an oxidizing agent. Solid and liquid phases are brought into contact after reaching a predetermined temperature, which is critically important in the study of the kinetics of dissolution of rhodium black and platinum plate due to the high rates of these processes. The concentrations of the metals in solutions are determined by atomic absorption spectroscopy and inductively coupled plasma mass spectrometry. The forms of chlorocomplexes of rhodium, iridium, and platinum in solutions are determined with a spectrophotometric method. As a result of the experiments, the modes of quantitative dissolution of a platinum plate and rhodium (in the form of affined powder and a plate) are determined and it is shown that, at 210°C in a medium of 6M hydrochloric acid with the addition of 5 vol % hydrogen peroxide, iridium taken in the form of affined powder dissolved by 50% in over 50 h, while the platinum plate dissolved completely at 130°C in about 120 min. An analysis of kinetic data using the shrinking core model showed that the rate determining the steps of the dissolution of rhodium black and affined rhodium and iridium powders under autoclave conditions were the chemical reactions. These results can be used both in analytical chemistry for quantitatively determining inert platinum metals and in refining production to improve the technology for processing raw materials containing platinum group metals (PGMs) and to optimize approaches to the synthesis of pure chlorocomplex compounds of PGMs.

Similar content being viewed by others

REFERENCES

Buslaeva, T.M. and Simanova, S.A., Platinum metals in aqueous hydrochloric and chloride solutions: Palladium, platinum, rhodium and iridium, Russ. J. Coord. Chem., 1999, vol. 25, no. 3, pp. 151–162.

Mpinga, C.N., Eksteen, J.J., Aldrich, C., and Dyer, L., Direct leach approaches to Platinum Group Metal (PGM) ores and concentrates: A review, Miner. Eng., 2015, no. 78, pp. 93–113. https://doi.org/10.1016/j.mineng.2015.04.015

Sahu, P., Jena, M.S., Mandre, N.R., and Venugopal, R., Platinum group elements mineralogy, beneficiation, and extraction practices—An overview, Miner. Process. Extr. Metall. Rev., 2020. https://doi.org/10.1080/08827508.2020.1795848

Gökelma, M., Birich, A., Stopic, S., and Friedrich, B., A review on alternative gold recovery re-agents to cyanide, J. Mater. Sci. Chem. Eng., 2016, vol. 4, no. 8, pp. 8–17. https://doi.org/10.4236/msce.2016.48002

Yu, L., Li, S., Liu, Q., Deng, J., Luo, B., Liang, Yu., Zhao, L., and Lai, H., Gold recovery from refractory gold concentrates by pressure oxidation pre-treatment and thiosulfate leaching, Physicochem. Probl. Miner. Process., 2019, vol. 55, no. 2, pp. 537–551. https://doi.org/10.5277/ppmp18166

Zaytsev, P.V., Fomenko, I.V., Chugaev, L.V., and Shneerson, Ya.M., Pressure oxidation of double refractory raw materials in the presence of limestone, Tsvetn. Met. (Moscow, Russ. Fed.), 2015, no. 8, pp. 41–49. https://doi.org/10.17580/tsm.2015.08.05

Simmon, G.L., Baughman, D.R., Gathje, J.C., and Oberg, K.C., Pressure oxidation problems and solutions: treating carbonaceous gold ores containing trace amounts of chlorine(halogens), Miner. Eng., 1998, vol. 50, no. 1, pp. 69–73.

Ding, Y., Zhang, S., Liu, B., Zheng, H., Chang, C.C., and Ekberg, C., Recovery of precious metals from electronic waste and spent catalysts: A review, Resour., Conserv. Recycl., 2019, vol. 141, pp. 284–298. https://doi.org/10.1016/j.resconrec.2018.10.041

Islam, A., Ahmed, T., Awual, M.R., Rahman, A., Sultana, M., Abd Aziz, A., and Hasan, M., Advances in sustainable approaches to recover metals from e-waste - A review, J. Cleaner Prod., 2020, vol. 244, p. 118815. https://doi.org/10.1016/j.jclepro.2019.118815

Salman, K. and Yen-Peng, T., Recycling pathways for platinum group metals from spent automotive catalyst: A review on conventional approaches and bio-processes, Resour., Conserv. Recycl., 2021, vol. 170, p. 105558. https://doi.org/10.1016/j.resconrec.2021.105588

Padamata, S.K., Yasinskiy, A.S., Polyakov, P.V., Pavlov, E.A., and Varyukhin, D.Y., Recovery of noble metals from spent catalysts: A review, Metall. Mater. Trans. B, 2020, vol. 51, no. 5, pp. 2413–2435. https://doi.org/10.1007/s11663-020-01913-w

Oraby, E.A., Li, H., and Eksteen, J.J., An alkaline glycine-based leach process of base and precious metals from powdered waste printed circuit boards, Waste Biomass Valorization, 2020, vol. 11, no. 8, pp. 3897–3909. https://doi.org/10.1007/s12649-019-00780-0

Batnasan, A., Haga, K., and Shibayama, A., Recovery of precious and base metals from waste printed circuit boards using a sequential leaching procedure, JOM, 2018, vol. 70, no. 2, pp. 124–128. https://doi.org/10.1007/s11837-017-2694-y

Miller, J.D., Wan, R.Y., and Diaz, X., Preg-robbing gold ores, in Gold Ore Processing, Amsterdam: Elsevier, 2016, pp. 885–907. https://doi.org/10.1016/B978-0-444-63658-4.00049-9.

Liu, G., Wu, Y., Tang, A., and Li, B., Recovery of scattered and precious metals from copper anode slime by hydrometallurgy: A review, Hydrometallurgy, 2020, vol. 197, p. 105460. https://doi.org/10.1016/j.hydromet.2020.105460

Upadhyay, A., Lee, J.-C., Kim, E., Kim, M.S., Kim, B.S., and Kumar, V., Leaching of platinum group metals (PGMs) from spent automotive catalyst using electro-generated chlorine in HCl solution, J. Chem. Technol. Biotechnol., 2013, vol. 88, pp. 1991–1999. https://doi.org/10.1002/jctb.4057

Lobko, S.V., Kuzas, E.A., Naboychenko, S.S., and Voinov, V.N., Electrochlorination of secondary raw materials containing precious metals using a volumetric current supply, Tsvetn. Met. (Moscow, Russ. Fed.), 2017, no. 3, pp. 45–49. https://doi.org/10.17580/tsm.2017.03.07

Belousov, O.V., Belousova, N.V., Borisov, R.V., and Ryumin, A.I., Extraction of trace elements from platinum group metal concentrates in hydrothermal conditions, Tsvetn. Met. (Moscow, Russ. Fed.), 2021, no. 6, pp. 23–30. https://doi.org/10.17580/tsm.2021.06.03

Belousov, O.V., Ryumin, A.I., Belousova, N.V., Bori-sov, R.V., Grizan, N.V., and Lobanova, O.N., Leaching of impurities from poor intermediate products of refining production in autoclave conditions, Russ. J. Appl. Chem., 2020, vol. 93, no. 7, pp. 1054–1058. https://doi.org/10.1134/S1070427220070162

Xingxiang, F., Yunan, Y., Lin, T., Yongjia, L., Sen, Y., Songyuan, Z., Zhihong, Y., Ni, Y., and Fabin, Z., Kinetics research on rhenium of the waste platinum-rhenium catalyst under pressure oxygen leaching, IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 439, no. 2, p. 022009. https://doi.org/10.1088/1757-899X/439/2/022009.

Hodgson, A.P.J., Jarvis, K.E., Grimes, R.W., and Marsden, O.J., Development of an iridium dissolution method for the evaluation of potential radiological device materials, J. Radioanal. Nucl. Chem., 2016, vol. 307, no. 3, pp. 2181–2186. https://doi.org/10.1007/s10967-015-4381-1

Mohanty, U.S., Kalliomäki, T., Seisko, S., Peng, C., Rintala, L., Halli, P., Aroma, J., Taskinen, P., and Lundström, M., Dissolution of copper and nickel from nickel-rich anode slimes under oxidized pressure leaching, Miner. Process. Extr. Metall., 2019. https://doi.org/10.1080/25726641.2019.1670008

Yang, Y., Gao, W., Xu, B., Li, Q., and Jiang, T., Study on oxygen pressure thiosulfate leaching of gold without the catalysis of copper and ammonia, Hydrometallurgy, 2019, vol. 187, pp. 71–80. https://doi.org/10.1016/j.hydromet.2019.05.006

Ubaldini, S., Leaching kinetics of valuable metals, Metals, 2021, vol. 11, no. 1, p. 173. https://doi.org/10.3390/met11010173

Belousova, N.V., Belousov, O.V., Borisov, R.V., and Grizan, N.V., Specific features of dissolution of metallic rhodium in acid oxidative media under hydrothermal conditions, Russ. J. Appl. Chem., 2019, vol. 92, no. 8, pp. 1102–1106. https://doi.org/10.1134/S107042721908007X

Borisov, R.V., Belousov, O.V., Dorokhova, L.I., and Zhizhaev, A.M., Features of fine iridium powders dissolution in acidic media, J. Sib. Fed. Univ., Chem., 2017, vol. 3, no. 10, pp. 325–332. https://doi.org/10.17516/1998-2836-0029

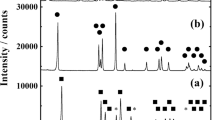

Borisov, R.V., Belousov, O.V., and Irtyugo, L.A., Thermostimulated transformations of highly disperse powders of platinum group metals in an argon atmosphere, Russ. J. Phys. Chem. A, 2014, vol. 88, no. 10, pp. 1732–1738. https://doi.org/10.1134/S0036024414100069

Levenspiel, O., Chemical Reaction Engineering, New York: John Wiley and Sons, 1972.

Hidalgoa, T., Kuharb, L., Beinlicha, A., and Putnisa, A., Kinetics and mineralogical analysis of copper dissolution from a bornite/chalcopyrite composite sample in ferric-chloride and methanesulfonic-acid solutions, Hydrometallurgy, 2019, vol. 188, pp. 140–156. https://doi.org/10.1016/j.hydromet.2019.06.009

Li, M., Wei, Ch., Qiu, Sh., Zhou, X., Li, C., and Deng, Zh., Kinetics of vanadium dissolution from black shale in pressure acid leaching, Hydrometallurgy, 2010, vol. 104, pp. 193–200. https://doi.org/10.1016/j.hydromet.2010.06.001

Ju, Zh.-J., Wang, Ch.-Y., and Yin, F., Dissolution kinetics of vanadium from black shale by activated sulfuric acid leaching in atmosphere pressure, Int. J. Miner. Process., 2015, vol. 138, pp. 1–5. https://doi.org/10.1016/j.minpro.2015.03.005

Funding

This work was carried out as part of the State Task of the Institute of Chemistry and Chemical Technology, Siberian Branch, Russian Academy of Sciences (project no. 0287-2021-0014), using equipment of the Krasnoyarsk Regional Center for Collective Use of the Federal Research Center, Krasnoyarsk Scientific Center, Siberian Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Belousova, N.V., Belousov, O.V., Borisov, R.V. et al. Autoclave Dissolution of Platinum Metals in Hydrochloric Acid Oxidizing Media. Russ. J. Non-ferrous Metals 62, 668–674 (2021). https://doi.org/10.3103/S1067821221060043

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221060043