Abstract

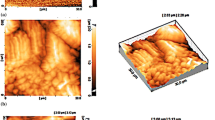

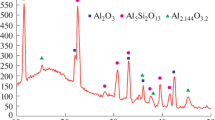

Microstructure of ceramic coatings formed on commercially pure aluminum by plasma electrolytic oxidation using different amounts of sodium silicate was studied. Analysis of chemical composition and microhardness measurements of the coatings were carried out to characterize the morphology of the coatings. The addition of sodium silicate (1–3 g/L) increased the thickness about 8 orders of magnitude and promotes the growth of the coatings. Chemical analysis of the coatings showed that with increasing sodium silicate concentration in the electrolyte from 1 to 3 g/L, the amount of manganese in the coatings was reduced ∼12%. The contribution of aluminum and silicon changed with a reciprocal relationship. When the concentration of Na2SiO3 changed from 1 to 2 g/L, the aluminium content was reduced about 26% and silicon increased about 80%. When the concentration of Na2SiO3 changed from 2 to 3 g/L, the aluminium content increased about 38% and the concentration of silicon reduced about 60%. The microhardness of the coatings was increased about 2 orders of magnitude by increasing the concentration of sodium silicate from 1 to 3 g/L.

Similar content being viewed by others

REFERENCES

Li, Q., Liang, J., and Wang, Q., Plasma Electrolytic Oxidation Coatings on Lightweight Metals, chapter 4 of Modern Surface Engineering Treatments, InTech, 2013.

Erfanifar, E., Aliofkhazraei, M., Fakhr Nabavi, H., Sharifi, H., and Sabour Rouhaghdam, A., Growth kinetics and morphology of plasma electrolytic oxidation coating on aluminum, Mater. Chem. Phys., 2017, vol. 185, pp. 162–175.

Sevidova, E., Gutsalenko, Y., Rudnev, A., Pupan, L., and Titarenko, O., The study of surface microgeometry and morphology of plasma electrolytic oxidation dielectric coatings on aluminum alloys, in Advances in Design, Simulation and Manufacturing II, Proceedings of the 2nd International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2019, June 11–14, 2019, Lutsk, Ukraine, Lecture Notes in Mechanical Engineering, Springer, 2020, pp. 302–310.

Yerokhin, A.L., Snizhko, L.O., Gurevina, N.L., Leyland, A., Pilkington, A., and Matthews, A., Discharge characterization in plasma electrolytic oxidation of aluminium, J. Phys. D: Appl. Phys., 2003, vol. 36, pp. 2110–2120.

Yerokhin, A.L., Nie, X., Leyland, A., Matthews, A., and Dowey, S.J., Plasma electrolysis for surface engineering, Surf. Coat. Technol., 1999, vol. 122, pp. 73–93.

Shamsi, F., Khorasanian, M., and Lari Baghal, S.M., Effect of potassium permanganate on corrosion and wear properties of ceramic coatings manufactured on CP-aluminum by plasma electrolytic oxidation, Surf. Coat. Technol., 2018, vol. 346, pp. 63–72.

Famiyeh, L. and Huang, X., Plasma electrolytic oxidation coatings on aluminum alloys: microstructures, properties, and applications, Mod. Concepts Mater. Sci., 2019, vol. 2, no. 1, pp. 1–13.

Polat, A., Makaraci, M., and Usta, M., Influence of sodium silicate concentration on structural and tribological properties of microarc oxidation coatings on 2017A aluminum alloy substrate, J. Alloys Compd., 2010, vol. 504, pp. 519–526.

Li, J., Cai, H., Xue, X., and Jiang, B., The outward-inward growth behavior of microarc oxidation coatings in phosphate and silicate solution, Mater. Lett., 2010, vol. 64, pp. 2102–2104.

Monfort, F., Berkani, A., Matykina, E., Skeldon, P., Thompson, G.E., Habazaki, H., and Shimizu, K., Development of anodic coatings on aluminium under sparking conditions in silicate electrolyte, Corros. Sci., 2007, vol. 49, pp. 672–693.

Guo-Hua, L.V., Wei-Chao, G.U., Huan, C., Li, L., Er-Wu, N., and Si-Ze, Y., Microstructure and corrosion performance of oxide coatings on aluminium by plasma electrolytic oxidation in silicate and phosphate electrolytes, Chin. Phys. Lett., 2006, vol. 23, no. 12, pp. 3331–3333.

Lugovskoy, A., Zinigrad, M., Kossenko, A., and Kazanski, B., Production of ceramic layers on aluminum alloys by plasma electrolytic oxidation in alkaline silicate electrolytes, Appl. Surf. Sci., 2013, vol. 264, pp. 743–747.

Rudnev, V.S., Yarovaya, T.P., Nedozorov, P.M., and Mansurov, Y.N., Wear-resistant oxide coatings on aluminum alloy formed in borate and silicate aqueous electrolytes by plasma electrolytic oxidation, Prot. Met. Phys. Chem. Surf., 2017, vol. 53, no. 3, pp. 466–474.

Terleeva, O.P., Slonova, A.I., Rogov, A.B., Kokovkin, V.V., and Mironov, I.V., Effect of chloride and sulphate anions as minor impurities in silicate alkaline electrolyte on plasma electrolytic oxidation of aluminium alloys, Mater. Res. Express, 2019, vol. 6, p. 015009.

Yang, Z., Wang, R.Q., Liu, C., Wu, Y.K., Wang, D.D., Liu, X.T., Zhang, X.Z., Wu, G.R., and Shen, D.J., The electrochemical corrosion behavior of plasma electrolytic oxidation coatings fabricated on aluminum in silicate electrolyte, J. Mater. Eng. Perform., 2019, vol. 28, no. 6, pp. 3652–3660.

Ali, M.M. and Sathiya, S., Evaluation on physico-chemical and corrosion properties of anodized aluminium surface using sodium oxalate-sodium silicate bath at room temperature, Curr. Sci., 2020, vol. 118, no. 2, pp. 234–242.

Saikiran, A., Hariprasad, S., Arun, S., Rama Krishna, L., and Rameshbabu, N., Effect of electrolyte composition on morphology and corrosion resistance of plasma electrolytic oxidation coatings on aluminized steel, Surf. Coat. Technol., 2019, vol. 372, no. 25, pp. 239–251.

Lee, J.H. and Kim, S.J., Effects of silicate ion concentration on the formation of ceramic oxide layers produced by plasma electrolytic oxidation on Al alloy, Jpn. J. Appl. Phys., 2017, vol. 56, p. 01AB01.

Agureev, L., Savushkina, S., Ashmarin, A., Borisov, A., Apelfeld, A., Anikin, K., Tkachenko, N., Gerasimov, M., Shcherbakov, A., Ignatenko, V., and Bogdashkina, N., Study of plasma electrolytic oxidation coatings on aluminum composites, Metals, 2018, vol. 8, no. 459, pp. 1–12.

Funding

The financial support of Shahid Chamran University of Ahvaz (grant no. 96/3/02/16670) should be kindly appreciated by the authors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares no conflict of interest.

About this article

Cite this article

Khorasanian, M., Shamsi, F. & Lari Baghal, S.M. Effect of Sodium Silicate Concentration on Morphology of Ceramic Coatings Produced on Commercially Pure Aluminum Using Plasma Electrolytic Oxidation. Russ. J. Non-ferrous Metals 61, 762–767 (2020). https://doi.org/10.3103/S1067821220060097

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220060097