Abstract

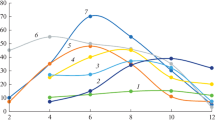

A series of models is investigated for describing the reduction of copper by fine zinc powder in aqueous solutions. The experiments were performed in apparatuses with a magnetic stirrer at 15–50°C and stirring rates of 40–150 rpm. The influence of high-molecular flocculants such as nonionogenic magnafloc 333, cationic besfloc 6645, and anion besfloc 4034 on this process is investigated. These flocculants are applied under industrial conditions at the stage of hydrolytic purification of solutions and then enter the cementation purification along with the settled solution. Aqueous solutions of flocculants of 2.5 g/L with dosages of zinc dust of 2–4 g/L and flocculant of 50–200 mg/L are used in experiments. The copper content is determined quantitatively in initial and final solutions by spectrophotometric analysis with the preliminary transfer of copper into an ammonia complex. The experiment duration varied from 1 to 8 min. The degree of reduction of copper reduced from solutions was 10–90%. It is established that the process kinetics at low stirring rates can be described by the first-order equation. The kinetics of the heterogeneous reaction under study at high stirring rates in the presence of flocculants additives is most adequately described by the equation of the variation in the rate as the root square of the process duration. It is shown that the largest cementation rate constant is observed without adding surfactants. The cementation is retarded to a smaller degree in the presence of the anionic flocculant when compared with the cationic one, which agrees with the theory of electrochemical processes and shows that the discharge of copper cations under these conditions limits the cementation. The regularities of the process under study are retained with an increase in temperature. It is noted that the additions of high-molecular substances with a relative molecular mass of 20 million in an amount of 50–200 mg/L retard cementation. This fact should be taken into account under industrial conditions where cementation purification with the removal of copper and other impurities is performed from solutions containing flocculants.

Similar content being viewed by others

REFERENCES

Kolesnikov, A.V. and Pratskova, S.E., Teoriya i praktika ochistki rastvorov tsinkovoi pyl’yu v gidrometallurgii. Eksperimental’nye i teoreticheskie dannye (Theory and Practice of Purification of Solutions of Zinc Dust in Hydrometallurgy. Experimental and Theoretical Data), Riga: Palmarium Academic, 2017.

Alkatsev, M.I., Protsessy tsementatsii v tsvetnoi metallurgii (Cementation Processes in Nonferrous Metallurgy), Moscow: Metallurgiya, 1981.

Aidarov, R.Zh., Aidarova, P.I., Shishkin, V.I., and Usenov, A.U., Influence of the copper content on the copper–cadmium purification of zinc electrolyte, Tsvetn. Metall., 1971, no. 2, pp. 27–29.

Salin, A.A., Revisiting deep purification of zinc electrolyte, Tsvetn. Met., 1964, no. 7, pp. 46–51.

Grigor’ev, V.D., Sadykov, S.B., Saprygin, A.F., and Naboichenko, S.S., Improvement of technology of removing impurities from zinc solutions using alloyed zinc dust, Tsvetn. Metall., 2004, no. 1, pp. 15–18.

Sarkisyan, N.S. and Episkoposyan, M.L., Kinetics of cadmium cementation with zinc from sulphate and chloride solutions, Tsvetn. Met., 1980, no. 2, pp. 24–26.

Krupkowa, Danuta, Cementation treatment of industrial solutions of zinc sulfate, Rud Imetaleniezel, 1979, vol. 24, no. 2, pp. 65–75.

Quathers, R., The method of purification of the electrolyte in hydrometallurgy of zinc, Metallurgie, 1976, vol. 16, no. 3, pp. 164–166.

Singh, V., Technological progress in the purification of zinc electrolyte at the hydrometallurgical plant, which reduced the consumption of zinc dust, Hydrometallurgy, 1996, vol. 40, nos. 1–2, pp. 247–262.

Levin, A.I., Revisiting the use surfactants in the electrochemistry of heavy nonferrous metals, Tsvetn. Met., 1980, no. 8, pp. 12–16.

Karavasteva, M., The influence of certain surfactants on the cementation of cobalt with zinc powder from zinc sulfate solutions, Can. Met. Quart., 2001, vol. 40, no. 2, pp. 179–184.

Karavasteva, M., Influence of surfactants on the cementation of nickel by zinc powder from zinc sulfate solutions in the presence of copper, Can. Met. Quart., 1999, vol. 38, no. 3, pp. 207–209.

Karavasteva, M., The effect of copper on the cementation of cadmium by zinc powder in the presence of surfactants, Hydrometallurgy, 1998, vol. 48, no. 3, pp. 361–366.

Kazanbaev, L.A., Kozlov, P.A., Kolesnikov, A.V., Boldyrev, V.V., Pavlov, A.D., and Chernyakov, M.A., RF Patent 2282671, 2006.

Antsinger, Andreas., On the influence of impurities in the electrolyte on the current output and specific power consumption of zinc solutions, Erzmetall, 1989, vol. 42, no. 12, pp. 553–559.

Vander Pas, V. and Dreisinger, D.B., Fundamental study of cobalt cementation by zinc dust in the presence of copper and antimony additives, Hydrometallurgy, 1996, vol. 41, no. 43, pp. 187–205.

Dajin Yang, Gang Xie, and Guisheng Zeng, The mechanism of removal of cobalt from zinc sulfate solutions in the presence of cadmium, Hydrometallurgy, 2006, vol. 81, no. 1, pp. 62–66.

Nelson, A., Demopoulos, G.P., and Houlachi, G., The effect of solution cons tituentsandnovel activatorson cobalt cementation, Can. Met. Quart., 2000, vol. 39, no. , pp. 175–186.

Prikladnaya elektrokhimiya: Uchebnik dlya vuzov (Applied Electrochemistry: Textbook for Higher School) Tomilov, A.P, Ed., Moscow: Khimiya, 1984.

Kolesnikov, A.V., Copper reduction with metallic zinc in aqueous solutions in the presence of high-molecular surfactants, Kond. Sredy Mezhfazn. Gran., 2016, vol. 18, no. 1, pp. 46–55.

Vol’dman, G.M. and Zelikman, A.N., Teoriya gidrometallurgicheskikh protsessov (Theory of Hydrometallurgical Processes), Moscow: Intermet Inzhiniring, 2003.

Berman, I.A., Revisiting the question of the research method and approach to the mechanism of heterogeneous reaction of displacement of more noble metal ions from the solution by less noble, Zh. Fiz. Khim., 1958, vol. 32, no. 9, pp. 1971–1979.

Alkatsev, M.I., Teoreticheskie osnovy protsessov tsementatsii (Theoretical Foundations of Cementation Processes) Vladikavkaz: Terek, 1994.

Rotinyan, A.L., Tikhonov, K.I., and Shoshina, I.A., Teoreticheskaya elektrokhimiya (Theoretical Electrochemistry), Rotinyan, A.L, Ed., Leningrad: Khimiya, 1981.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors claim that they have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Kolesnikov, A.V., Tsyganova, I.V. Investigation into the Influence of Flocculants on Kinetic Parameters of Reducing Copper in an Aqueous Solution by Metallic Zinc. Russ. J. Non-ferrous Metals 60, 341–347 (2019). https://doi.org/10.3103/S1067821219040060

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821219040060