Abstract

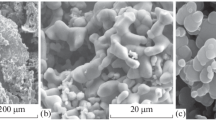

This article is devoted to the investigation into the combustion kinetics and mechanism of reaction mixtures in Zr–Si–B and Zr–B systems formed according to the forced SHS-pressing of compact ceramic materials, as well as to studying their heat resistance. It is shown that dependences of the combustion temperature and rate on the initial temperature (T0) for compositions in the Zr–Si–B system are linear; i.e., staging of chemical reactions of formation of zirconium diboride and disilicide remains invariable with an increase in T0. The values of effective activation energy of SHS process, which evidence the leading role of the reaction interaction of zirconium with boron and silicon in the melt, are calculated. Staging of chemical transformations in the combustion wave of the Zr–Si–B system is investigated: initially the ZrB2 phase is formed by crystallization from the melt, and then the ZrSi2 phase appears with a delay of 0.5 s; unreacted Si crystallizes after 1 s. The phase composition of synthesis products, in which the main component is ZrB2 diboride, and zirconium disilicide, Si, and ZrB12 boride are contained depending on the composition of the reaction charge, is investigated. Compact samples having high hardness and low residual porosity are fabricated according to forced SHS-pressing technology. High-temperature oxidation of SHS samples results in the formation of SiO2–ZrO2–B2O3 oxide films and ZrSiO4 complex oxide on their surface depending on the composition, which serve the effective diffusion barrier and lower the oxidation rate.

Similar content being viewed by others

References

Sha, J.J., Li, J., Wang, S.H., Wang, Y.C., Zhang, Z.F., and Dai, J.X., Toughening effect of short carbon fibers in the ZrB2–ZrSi2 ceramic composites, Mater. Des., 2015, vol. 75, pp. 160–165.

Paul, A., Jayaseelan, D.D., Venugopal, S., Zapata-Solvas, E., Binner, J., Vaidhyanathan, B., Heaton, A., Brown, P., and Lee, W.E., UHTS composites for hypersonic applications, Am. Ceram. Soc. Bull., 2012, vol. 91, pp. 22–29.

Czelusniak, T., Amorim, F.L., Higa, C.F., and Lohrengel, A., Development and application of new composite materials as EDM electrodes manufactured via selective laser sintering, Int. J. Adv. Manuf. Technol., 2014, vol. 72, pp. 1503–1512.

Chamberlain, A.L., Fahrenholtz, W.G., Hilmas, G.E., and Ellerby, D.T., Highstrength zirconium diboridebased ceramics, J. Am. Ceram. Soc., 2004, vol. 87, pp. 1170–1172.

Sciti, D., Guicciardi, S., and Silvestroni, L., SiC chopped fibers reinforced ZrB2 effect of the sintering aid, Scr. Mater., 2011, vol. 64, pp. 769–772.

Sciti, D., Silvestroni, L., Saccone, G., and Alfano, D., Effect of different sintering aids on thermo-mechanical properties and oxidation of SiC fibers-reinforce ZrB2 composites, Mater. Chem. Phys., 2013, vol. 137, pp. 834–842.

Guo, S.Q., Kagawa, Y., and Nishimura, T., Mechanical behavior of two-step hotpressed ZrB2-based composites with ZrSi2, J. Eur. Ceram. Soc., 2009, vol. 29, pp. 787–794.

Wang, H.L., Wang, C.A., Yao, X.F., and Fang, D.N., Processing and mechanical properties of zirconium diboride-based ceramics prepared by spark plasma sintering, J. Am. Ceram. Soc., 2007, vol. 90, pp. 1992–1997.

Pastor, H., Metallic borides: preparation of solid bodies— sintering methods and properties of solid bodies, in: Boron and Refractory Borides, Matkovich, V.I., Ed., New York: Springer, 1977, pp. 454–493.

Silvestroni, L. and Sciti, D., Densification of ZrB2–TaSi2 and HfB2–TaSi2 ultrahigh-temperature ceramic composites, J. Am. Ceram. Soc., 2011, vol. 94, pp. 1920–1930.

Sciti, D., Guicciardi, S., and Silvestroni, L., Are short Hi-Nicalon SiC fibers a secondary or a toughening phase for ultra-high temperature ceramics, Mater. Des., 2014, vol. 55, pp. 821–829.

Yang, F.Y., Zhang, X.H., Han, J.C., and Du, S.Y., Processing and mechanical properties of short carbon fibers toughened zirconium diboride-based ceramics, Mater. Des., 2008, vol. 29, pp. 1817–1820.

Lin, J., Zhang, X.H., Wang, Z., Han, W.B., and Jin, H., Microstructure and mechanical properties of hot-pressed ZrB2–SiC–ZrO2 ceramics with different sintering temperatures, Mater. Des., 2012, vol. 34, pp. 853–856.

Sha, J.J., Wei, Z.Q., Li, J., Zhang, Z.F., Yang, X.L., Zhang, Y.C., and Dai, J.X., Mechanical properties and toughening mechanism of WC-doped ZrB2–ZrSi2 ceramic composites by hot pressing, Mater. Des., 2014, vol. 62, pp. 199–204.

Sciti, D., Guicciardi, S., and Bellosi, A., Properties of a pressureless-sintered ZrB2–MoSi2 ceramic composite, J. Am. Ceram. Soc., 2006, vol. 7, pp. 2320–2322.

Guo, S.Q., Kagawa, Y., Nishimura, T., and Tanaka, H., Pressureless sintering and physical properties of ZrB2-based composites with ZrSi2 additive, Scr. Mater., 2008, vol. 58, pp. 579–582.

Yu-Lei Zhang, He-Jun Li, Zhi-Xiong Hu, Jin-Cui Ren, and Ke-Zhi Li, Microstructure and oxidation resistance of Si–Mo–B coating for C/SiC coated carbon/carbon composites, Corros. Sci., 2013, vol. 72, pp. 150–155.

Feng, T., Li, H.J., Shi, X.H., Yang, X., Li, Y.X., and Yao, X.Y., Sealing role of B2O3 in MoSi2–CrSi2–Si/B modified coating for C/C composites, Corros. Sci., 2012, vol. 60, pp. 4–9.

Grigoriev, O., Galanov, B., Lavrenko, V., Panasyuk, A., Ivanov, S., Koroteev, A., and Nickel, K., Oxidation of ZrB2–SiC–ZrSi2 ceramics in oxygen, J. Eur. Ceram. Soc., 2010, vol. 30, pp. 2397–2405.

Silvestroni, L., Landi, E., Bejtka, K., Chiodoni, A., and Sciti, D., Oxidation behavior and kinetics of ZrB2 containing SiC chopped fibers, J. Eur. Ceram. Soc., 2015, vol. 35, pp. 4377–4387.

Silvestroni, L., Meriggi, G., and Sciti, D., Oxidation behavior of ZrB2 composites doped with various transition metal silicides, Corros. Sci., 2014, vol. 83, pp. 281–291.

Makarov, A.V., Bagarat’yan, N.V., Zbezhneva, S.G., Aleshko-Ozhevskaya, L.A., and Georgobiani, T.P., Ionization and fragmentation of B2O2 and BOmolecules under electronic blow, Vestn. Mosk. Gos. Univ., Ser. Khim., 2000, vol. 41, no. 4, pp. 227–230.

Eremina, E.N., Kurbatkina, V.V., Levashov, E.A., Rogachev, A.S., and Kochetov, N.A., Obtaining the composite MoB material by means of force SHS compacting with preliminary mechanical activation of Mo–10% B mixture, Chem. Sustain. Develop., 2005, vol. 13, pp. 197–204.

Khanraa, A.K., Pathak, L.C., and Godkhindi, M.M., Double SHS of ZrB2 powder, J. Mater. Proc. Technol., 2008, vol. 202, pp. 386–390.

Levashov, E.A., Rogachev, A.S., Kurbatkina, V.V., Maksimov, M., and Yukhvid, V.I., Perspektivnye materialy i tekhnologii samorasprostranyayushchegosya vysokotemperaturnogo sinteza (Promising Materials and Processes of Self-Propagating High-Temperature Synthesis), Moscow: MISIS, 2011.

Levashov, E.A., Pogozhev, Yu.S., Potanin, A.Yu., Kochetov, N.A., Kovalev, D.Yu., Shvyndina, N.V., and Sviridova, T.A., Self-propagating high-temperature synthesis of advanced ceramics in the Mo–Si–B system: Kinetics and mechanism of combustion and structure formation, Ceram. Int., 2014, vol. 40, pp. 6541–6552.

Rogachev, A.S. and Mukasyan, A.S., Combustion for Materials Synthesis, New York: Taylor and Francis, 2015.

Pogozhev, Yu.S., Potanin, A.Yu., Levashov, E.A., and Kovalev, D.Yu., The features of combustion and structure formation of ceramic materials in the Cr–Al–Si–B system, Ceram. Int., 2014, vol. 40, pp. 16299–16308.

Bertolino, N., Anselmi-Tamburini, U., Maglia, F., Spinolo, G., and Munir, Z.A., Combustion synthesis of Zr–Si intermetallic compounds, J. Alloys Compd., 1999, vol. 288, pp. 238–248.

Levashov, E.A., Kurbatkina, V.V., Rogachev, A.S., Kochetov, N.A., Patsera, E.I., and Sachkova, N.V., Characteristic properties of combustion and structure formation in the Ti–Ta–C system, Russ. J. Non-Ferrous Met., 2008, vol. 49, pp. 404–413.

Patsera, E.I., Levashov, E.A., Kurbatkina, V.V., and Kovalev, D.Yu., Production of ultra-high temperature carbide (Ta, Zr)C by self-propagating high-temperature synthesis of mechanically activated mixtures, Ceram. Int., 2015, vol. 41, pp. 8885–8893.

Yu, Y., Luo, R., Xiang, Q., Zhang, Y., and Wanga, T., Antioxidation properties of a BN/SiC/Si3N4–ZrO2–SiO2 multilayer coating for carbon/carbon composites, Surf. Coat. Technol., 2015, vol. 277, pp. 7–14.

Liu, J., Cao, L.-Y., Huang, J.-F., Xin, Y., Yang, W.-D., Fei, J., and Yao, C.-Y., A ZrSiO4/SiC oxidation protective coating for carbon/carbon composites, Surf. Coat. Technol., 2012, vol. 206, pp. 3270–3274.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.V. Iatsyuk, Yu.S. Pogozhev, E.A. Levashov, A.V. Novikov, N.A. Kochetov, D.Yu. Kovalev, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2017, No. 1, pp. 29–41.

About this article

Cite this article

Iatsyuk, I.V., Pogozhev, Y.S., Levashov, E.A. et al. Features of Production and High-Temperature Oxidation of SHS Ceramics Based on Zirconium Boride and Zirconium Silicide. Russ. J. Non-ferrous Metals 59, 311–322 (2018). https://doi.org/10.3103/S1067821218030173

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218030173