Abstract

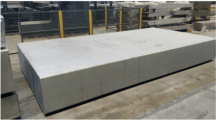

The urgency of works directed at the fabrication of new alloys of the Al–Mg system alloyed with scandium, which are characterized by a profitable combination of operational and mechanical properties such as weldability, corrosion resistance, and sufficient strength, is shown. Flat ingots of the experimental scandium-containing alloy 560 × 1360 × 4520 mm in size are fabricated in industrial conditions. Modes of thermal treatment and sheet rolling are developed and approved for billets with a maximal thickness of 40 mm cut from them. A DUO 330 mill with flat rolls with an initial diameter of 330 mm and barrel width of 540 mm is used as the rolling equipment. Experimental investigations, which include the preparation of billets to rolling (homogenizing annealing and face milling), hot rolling at 450°C, cold rolling to a thickness of 3 mm, and annealing of cold-deformed semifinished products, result in the fabrication of deformed semifinished products fabricated according to various schemes of reduction during rolling and passed heat treatment. The maximal degree of summary deformation while rolling the billets to a thickness of 3 mm is 92.5%, while drawing for the passage varies from 1.04 to 1.2. Mechanical properties of deformed and annealed semifinished products of various thicknesses made of the experimental alloy are determined using an LFM400 universal test machine with an effort of 400 kN according to GOST (State Standard) 1497–84 and regularities of their variation, depending on the summary degree of deformation during rolling, are revealed. It is established that, when rolling strips made of the experimental scandium-containing aluminum alloy, the temporary tensile strength and yield strength of the material increase, while the relative elongation decreases, which corresponds to general ideas of the theory of metal forming. An analysis of the mechanical properties of the semifinished products shows that the level of strength and plastic properties is rather high, wherein the temporary tensile strength for cold-deformed samples reaches 453–481 MPa, the yield strength of metal reaches 429–457 MPa, and the relative elongation reaches 3.8–5.0%. The application of annealing made it possible to increase the relative elongation to 14–16% at sufficiently high values of the yield strength (up to 277 MPa). The results of our investigations allow us to develop the modes of casting, rolling, and annealing for the preparation of semifinished products made of the alloy of the Al–Mg system economically alloyed with scandium in limits of 0.10–0.14%, which will be used when approving the machining technologies in industrial conditions.

Similar content being viewed by others

References

Kablov, E.N., Ospennikova, O.G., and Vershkov, A.V., Rare metals and rare-earth elements—materials for modern and future high technologies, Tr. VIAM: Elektron. Nauch. Zh., 2013, no. 2, p. 1.

Gorbunov, Yu.A., Role and prospects of rare-earth metals in the development of physicomechanical characteristics and application regions of deformed alumi-num alloys, Zh. SFU, ser. Tekh. Tekhnol., 2015, vol. 8, no. 5, pp. 636–645.

Malopheyev, S., Kulitskiy, V., and Kaibyshev, R., Deformation structures and strengthening mechanisms in an Al–Mg–Sc–Zr alloy, J. Alloys Compd., 2017, vol. 698, pp. 957–966.

Kang, W., Li, H.Y., Zhao, S.X., Han, Y., Yang, C.L., and Ma, G., Effects of homogenization treatments on the microstructure evolution, microhardness and electrical conductivity of dilute Al–Sc–Zr–Er alloys, J. Alloys Compd., 2017, vol. 704, pp. 683–692.

Roumina, R. and Sinclair, C.W., Recovery kinetics in the presence of precipitates: The softening response of an Al–Mg–Sc alloy, Acta Mater., 2010, vol. 58, pp. 111–121.

Krug, M.E., Werber, A., Dunand, D.C., and Seidman, D.N., Core-shell nanoscale precipitates in Al–0.06 at % Sc microalloyed with Tb, Ho, Tm or Lu, Acta Mater., 2010, vol. 58, pp. 134–145.

De Luca, A., Dunand, D.C., and Seidman, D.N., Mechanical properties and optimization of the aging of a dilute Al–Sc–Er–Zr–Si alloy with a high Zr/Sc ratio, Acta Mater., 2016, vol. 119, pp. 35–42.

Riddle, Y.W. and Sanders Jr., T.H., A study of coarsening, recrystallization, and morphology of microstructure in Al–Sc–(Zr)–(Mg) alloys, Metal. Mater. Trans. A, 2004, vol. 35A, pp. 341–350.

Zhu, H., Dahle, A.K., and Ghosh, A.K., Effect of Sc and Zn additions on microstructure and hot formability of Al–Mg sheet alloys, Metal. Mater. Trans. A, 2009, vol. 40A, pp. 598–608.

Shi, C., Zhang, L., Wu, G., Zhang, X., Chen, A., and Tao, J., Effects of Sc addition on the microstructure and mechanical properties of cast Al–3Li–1.5Cu–0.15Zr alloy, Mater. Sci. Eng., 2017, vol. A680, pp. 232–238.

Pedro Henrique R. Pereiraa, Ying Chun Wang, Yi Huang, and Terence G. Langdon, Influence of grain size on the flow properties of an Al–Mg–Sc alloy over seven orders of magnitude of strain rate, Mater. Sci. Eng., 2017, vol. A685, pp. 367–376.

Mondol, S., Alamb, T., Banerjee, R., Kumar, S., and Chattopadhyay, K., Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy, Mater. Sci. Eng., 2017, vol. A687, pp. 221–231.

Li, M., Pan, Q., Shi, Y., Sun, X., and Xiang, H., High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling, Mater. Sci. Eng., 2017, vol. A687, pp. 298–305.

Buranova, Yu., Kulitskiy, V., Peterlechner, M., Mogucheva, A., Kaibyshev, R., Divinski, S.V., and Wilde, G., Al3(Sc, Zr)-based precipitates in Al–Mg alloy: Effect of severe deformation, Acta Mater., 2017, vol. 124, pp. 210–224.

Ibrokhimov, S.Zh., Eshov, B.B., Ganiev, I.N., and Ibrokhimov, N.F., Influence of scandium on physicochemical properties of the AMg4 alloy, Izv. Samar. Nauch. Tsentr. Ross. Akad. Nauk, 2014, vol. 16, no. 4, pp. 256–260.

Ibrokhimov, S.Zh., Eshov, B.B., and Ganiev, I.N., Oxidation of solid aluminum–magnesium AMg4 alloy alloyed with scandium, Dokl. Akad. Nauk Resp. Tadzhikistan, 2013, vol. 56, no. 6, pp. 472–475.

Filatov, Yu.A., Different approaches to implementation of the strengthening effect caused by the addition of scandium in deformed alloys based on the Al–Mg–Sc system, VILS: Tekhnol. Legk. Splav., 2009, no. 3, pp. 42–45.

Filatov, Yu.A., Deformable alloys based on the Al–Mg–Sc system, Metalloved. Term. Obrab. Met., 1996, no. 6, pp. 33–36.

Filatov, Yu.A., Deformable Al–Mg–Sc alloys and possible fields of their application, Perspekt. Mater., 1996, no. 5, pp. 45–49.

Kuznetsov, G.M., Pobezhimov, P.P., Nefedova, L.P., and Belov, E.V., Formation peculiarities of the structure and properties of cast Al–Mg alloys alloyed with scandium, Metalloved. Term. Obrab. Met., 1996, no. 6, pp. 30–32.

Drits, M.E., Kadaner, E.S., Dobatkina, T.V., and Turkina, N.I., Revisited the interaction character of scandium with aluminum in the aluminum-enriched part of the system, Izv. Akad. Nauk SSSR, 1973, no. 4, pp. 213–217.

Yakiv’yuk, O.V., Sidelnikov, S.B., Dovzhenko, N.N., Frolov, V.F., Krokhin, A.Yu., Bezrukikh, A.I., and Frolov, V.A. Research of manufacturability of processing and properties of rolling made of aluminum alloys of the Al–Mg system economically alloyed with scandium, Abstracts of Papers, Tsvetnye metally i mineraly 2016 (Nonferrous Metals and Minerals 2016), Krasnoyarsk: Nauch.-Innovats. Tsentr, 2016, pp. 262–263.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.N. Baranov, S.B. Sidelnikov, E.Yu. Zenkin, D.S. Voroshilov, 2018, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Tsvetnaya Metallurgiya, 2018, No. 2, pp. 45–51.

About this article

Cite this article

Baranov, V.N., Sidelnikov, S.B., Zenkin, E.Y. et al. Development of Fabrication Modes of Deformed Semifinished Products from the Experimental Scandium-Containing Aluminum Alloy and Investigation into Their Mechanical Properties. Russ. J. Non-ferrous Metals 59, 62–66 (2018). https://doi.org/10.3103/S1067821218010042

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218010042