Abstract

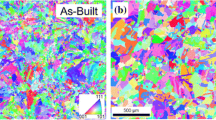

In powder-blown additive manufacturing, the microstructure and mechanical characteristics of the deposited layers are influenced greatly by the process parameters used. The microstructures and mechanical properties of the 1718 nickel alloy processed by additive manufacturing were investigated in this research. The samples were subsequently used to prepare metallographic specimens for observations by optical microscopy and scanning electron microscopy, and hardness test. It was found that the fine equiaxed grains are presented in the build and side surface. There is no difference of the microstructure along the build direction. Subsequently, the hardness is uniform along the thickness and the value is around 260 HV. The potential application includes imitation jewelry and holloware.

Similar content being viewed by others

References

Kruth, J.P., Froyen, L., van Vaerenbergh, J., Mercelis, P., Rombouts, M., and Lauwers, B, Selective laser melting of iron-based powder, J. Mater. Process. Technol., 2004, vol. 149, no. 1, pp. 616–622.

Gu, D.D., Meiners, W., Wissenbach, K., and Poprawe, R, Laser additive manufacturing of metallic components: Materials, processes and mechanisms, Int. Mater. Rev., 2012, vol. 57, no. 3, pp. 133–164.

Khan, Mushtaq and Dickens, Ph., Selective laser melting (SLM) of pure gold, Gold Bull., 2010, vol. 3, no. 2, pp. 114–121.

Facchini, L., Magalini, E., Robotti, P., Molinari, A., Hoges, S., and Wissenbach, K, Ductility of a Ti–6Al–4V alloy produced by selective laser melting of prealloyed powders, Rapid Prototyping J., 2010, vol. 16, no. 6, pp. 450–459.

Tolosa, I., Garciandia, F., Zubiri, F., Zapirain, F., and Esnaola, A, Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies, Int. J. Adv. Manufact. Technol., 2010, vol. 51, nos. 5–8, pp. 639–647.

Chamanfar, A., Sarrat, L., Jahazi, M., Asadi, M., Weck, A., and Koul, A.K, Microstructural characteristics of forged and heat treated Inconel-718 disks, Mater. Design, 2013, vol. 52, pp. 791–800.

Amato, K.N., Gaytan, S.M., Murr, L.E., Martinez, E., Shindo, P.W., Hernandez, J., Collins, S., and Medina, F, Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting, Acta Materialia, 2012, vol. 60, no. 5, pp. 2229–2239.

Zhang, Y., Cao, X., Wanjara, P., and Medraj, M, Fiber laser deposition of Inconel 718 using powders, Materials Science and Technology (MS&T), Montreal, Quebec, Canada, 2013, pp. 37–49.

Wang, Z., Guan, K., Gao, M., Li, X., Chen, X., and Zeng, X, The microstructure and mechanical properties of deposited-IN718 by selective laser melting, J. Alloys Compd., 2012, vol. 513, pp. 518–523.

Matthey, J., The 28th Santa Fe Symposium on Jewelry Manufacturing Technology, Johnson Matthey Technology Review, p. 189.

Mushtaq Khan and Dickens, Ph., Selective laser melting (SLM) of gold (Au), Rapid Prototyping J., 2012, vol. 18, issue 1, pp. 81–94.

Jhabvala, Jamasp, Boillat Eric, and Glardon Remy, On the use of EBSD analysis to investigate the microstructure of gold samples built by selective laser melting, Gold Bull., 2011, vol. 44, no. 2, pp. 113–118.

Fan, Z. and Liou, F., Numerical modeling of the additive manufacturing (AM) processes of titanium alloy, Titanium Alloys—Towards Achieving Enhanced Properties for Diversified Applications, vol. 1.

Liu, F., Lin, X., Yang, G., Song, M., Chen, J., and Huang, W, Recrystallization and its influence on microstructures and mechanical properties of laser solid formed nickel base superalloy Inconel 718, Rare Metals, 2011, vol. 30, no. 1, pp. 433–438.

Nie, Pulin, Ojo, O.A., and Zhuguo Li, Numerical modeling of microstructure evolution during laser additive manufacturing of a nickel-based superalloy, Acta Materialia, 2014, vol. 77, pp. 85–95.

Parimi, L.L., Ravi, G.A., Clark, D., and Attallah, M.M, Microstructural and texture development in direct laser fabricated IN718, Mater. Characterization, 2014, vol. 89, pp. 102–111.

Vrancken, B., Thijs, L., Kruth, J.P., and van Humbeeck, J, Microstructure and mechanical properties of a novel titanium metallic composite by selective laser melting, Acta Materialia, 2014, vol. 68, pp. 150–158.

Farshidianfar, M.H., Control of microstructure in laser additive manufacturing, Thesis, University of Waterloo, 2014.

McCartney, D.G. and Hunt, J.D, Measurements of cell and primary dendrite arm spacings in directionally solidified aluminium alloys, Acta Metall., 1981, vol. 29, no. 11, pp. 1851–1863.

Somboonsuk, K., Mason, J.T., and Trivedi, R, Interdendritic spacing, Part I: Experimental studies, Metall. Trans. A, 1984, vol. 15, no. 6, pp. 967–975.

Bouchard, D. and Kirkaldy, J.S, Prediction of dendrite arm spacings in unsteady-and steadystate heat flow of unidirectionally solidified binary alloys, Metall. Mater. Trans. B, 1997, vol. 28, no. 4, pp. 651–663.

Gong, X. and Chou, K, Microstructures of Inconel 718 by selective laser melting, TMS2015 Supplemental Proceedings, 2015, pp. 461–468.

Gong, X., Lydon, J., Cooper, K., and Chou, K, Beam speed effects on Ti–6Al–4V microstructures in electron beam additive manufacturing, J. Mater. Res., 2014, vol. 29, no. 17, pp. 1951–1959.

Gong, X., Lydon, J., Cooper, K., and Chou, K, Microstructural analysis and nanoindentation characterization of Ti–6Al–4V parts from electron beam additive manufacturing, ASME 2014 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, 2014, pp. V02AT02A004–V02AT02A004.

Song, K.H., Kim, W.Y., and Nakata, K, Investigation of microstructure and mechanical properties on surface- modified Inconel 718 alloy, Mater. Trans., 2013, vol. 54, no. 10, pp. 2032–2036.

Baufeld, B, Mechanical properties of Inconel 718 parts manufactured by shaped metal deposition (SMD), J. Mater. Eng. Performance, 2012, vol. 21, no. 7, pp. 1416–1421.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Luo, L., Gong, X. Microstructures and mechanical properties in powder-based additive manufacturing of a nickel-based alloy. Russ. J. Non-ferrous Metals 58, 269–275 (2017). https://doi.org/10.3103/S1067821217030129

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821217030129