Abstract

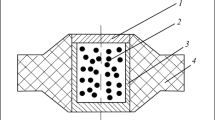

The results of the investigation into the compaction (sintering) of silicon carbide nanopowders and micropowders in a DO-138 high-pressure apparatus are presented. Compaction modes for both types of materials are identical (a pressure of 3.5–4.0 GPa, a temperature of 1600—1700°C, and a holding time of 10 s). The influence of cladding of SiC nanopowders and micropowders with titanium and titanium nitride on the properties of compacts (cakes) formed under the same sintering modes is investigated. It is established that, when compacting the silicon carbide nanopowder, cakes differ in regards to higher density, hardness, and lower porosity compared with the samples made of finely dispersed technical silicon carbide. A higher activity of titanium relative to SiC makes it possible to chemically associate the grains of the latter due to the formation of intermediate layers of titanium carbide between them. The resulting ceramics possesses a higher density, hardness, and wear resistance. The wear resistance of synthesized composites based on nano-SiC is higher than for a polycrystalline material based on silicon carbide micropowder by a factor of 4.5.

Similar content being viewed by others

References

Shaffer, T.B., Fine SiC powders for high performance ceramics, Ceram. Eng. Sci. Proc, 1985, no. 6, pp. 1289–1295.

Knoch, H. and Hunold, K., Eigenschaften und Anwendungsleispiele Nochoxidischer Sonderkeramischer Werkstoffe, Keram. Z., 1996, no. 1, pp. 25–28.

Hausner, H., Oxidische und Nochoxidische Sinterpulver, Techn. Mitt, 1997, no. 5, pp. 208–209.

Nasataka, V., Present state of silicon carbide powder, Ceram. Jap, 1997, no. 1, pp. 46–51.

Schwier, G. and Nietfeld, G., Siliciumnitrid und Siliciumcarbid—Pulver fur die Hochleistungkeramic, Sprechsaal, 1998, vol. 31, no. 3, p. 175.

Rudneva, V.V., Physicochemical attestation of nanodimensional silicon carbide powder, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2006, no. 5, p. 20.

Rudneva, V.V., The Improvement of the Plasma Metallurgical Production Technology of Silicon Carbide Nanopowders, Extended Abstract of Doctoral (Eng.) Dissertation, Novokuznetsk, Sib. Gos. Industrial. Univ., 2009.

Rudneva, V.V., Galevskii, G.V., and Yurkova, E.K., The investigation of the morphology and particle size of silicon carbide nanopowders using electron microscopy, Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokryt., 2009, no. 3, p. 32.

Rudneva, V.V., Galevskii, G.V., and Yurkova, E.K., The compaction of silicon carbide and compositions based on it (the analysis of the domestic and foreign experience), Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2009, no. 3, p. 56.

Rudneva, V.V., Nanomaterialy i nanotekhnologii v proizvodstve karbida kremniya (Nanomaterials and Nanotechnologies in Silicon Carbide Production), Moscow: Nauka, 2007, vol. 3.

Garshin, A.P. and Fedotova, S.M., Abrazivnye materialy i instrumenty. Tekhnologiya proizvodstva (Abrasive Materials and Instruments. Production Technology), St. Petersburg: St. Petersburg Politekh. Univ., 2008.

Sintez sverkhtverdykh materialov. T. 2. Kompozitsionnye instrumental’nye sverkhtverdye materialy (Synthesis of Superhard Materials. Vol. 2. Composite Tool Superhard Materials) Novikov, N.V., Ed., Kiev: Naukova Dumka, 1986.

Shul’zhenko, A.A., Gargin, V.G., Shishkin, V.A., et al., Polikristallicheskie materialy na osnove almaza (Polycrystalline Diamond-Based Materials), Novikov, N.V., Ed., Kiev: Naukova Dumka, 1989.

Shul’zhenko, A.A., Bozhko, A.N., Sokolov, A.N., et al., Sintez, spekanie i svoistva kubicheskogo nitrida bora (Synthesis, Sintering, and Properties of Cubic Boron Nitride), Novikov, N.V., Ed., Kiev: Naukova Dumka, 1993.

Bogdanov, S.P., Preparation of coatings on powders by the iodide transport method, Glass Phys. Chem., 2011, vol. 37, no. 2, p. 172.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Original Russian Text © A.P. Garshin, S.P. Bogdanov, V.A. Ponomarenko, 2015, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2015, No. 2, pp. 15–20.

About this article

Cite this article

Garshin, A.P., Bogdanov, S.P. & Ponomarenko, V.A. Investigation into the compaction of nanopowders and micropowders of silicon carbide in high-pressure apparatus. Russ. J. Non-ferrous Metals 57, 484–488 (2016). https://doi.org/10.3103/S1067821216050059

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821216050059