Abstract

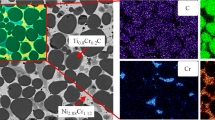

The phase composition, structure, and properties of self-propagating high-temperature synthesis (SHS)-compacted materials of the Ti-C-Al-Si system are investigated. It is shown that metal-like titanium compounds can be used as cathodes for vacuum-arc evaporators. The coatings fabricated from SHS cathodes are single-phase and represent cubic titanium nitride of the (Ti, Al, Si)N composition. The volume of a microdrop phase in them is smaller by a factor of 2.5–3.0 as compared with TiN, while their microstructure is not fragmented into low-strength columnar elements; the CSR size is twice smaller than that of titanium nitride. Being approximately identically hard, the (Ti, Al, Si)N coatings substantially surpass TiN coatings in elastic and plastic failure resistance due to the lower elasticity modulus. When milling the tungsten-copper alloy, the hardness of hard-alloy milling cutters with the (Ti, Al, Si)N coating is higher by a factor of 2.4 than with the TiN coating fabricated from the titanium cathode with the magnetic plasma flow separation.

Similar content being viewed by others

References

Reshetnyak, E.N. and Strel’nitskii, V.E., Vopr. At. Nauki Tekh., Ser. Fiz. Radiat. Povrezhd. Radiat. Materialoved., 2008, vol. 2, p. 119.

Amosov, A.P., Latukhin, E.I., Fedotov, A.F., et al., Izv. Vuzov. Poroshk. Metal. Funkts. Pokryt., 2011, no. 1, p. 46.

Levashov, E.A., Pogozhev, Yu.S., Rogachev, A.S., et al., Izv. Vuzov. Poroshk. Metal. Funkts. Pokryt., 2010, no. 3, p. 27.

Vadchenko, S.G., Ponomarev, V.I., and Sychev, A.E., Fiz. Goreniya Vzryva, 2006, vol. 42, no. 2, p. 53.

Zhang, E., Zeng, S., Zeng, X., et al., Acta Metall. Sinica, 1995, vol. 8, no. 2, p. 130.

Jin, S., Shen, P., Zou, B., and Jiang, Q., Crystal Growth & Design, 2009, vol. 9, no. 2, p. 646.

Rogachev, A.S., Gachon, J.-C., Grigoryan, H.E., et al., J. Mater. Sci., 2005, vol. 40, p. 2689.

Levashov, E.A., Pogozhev, Yu.S., Shtanskii, D.V., and Petrzhik, M.I., Izv. Vuzov. Poroshk. Metal. Funkts. Pokryt., 2008, no. 3, p. 13.

Vacuum Arcs. Theory and Application, J. M. Lafferty, Ed., New York: Wiley, 1980, pp. 228–320.

J. Emsley, The Elements, Oxford: Clarendon, 1998, 3rd ed.

Samsonov, G.V. and Vinnitskii, I.M., Tugoplavkie soedineniya: Spravochnik (Refractory Compounds: Handbook), Moscow: Metallurgiya, 1976.

Samsonov, G.V., Dvorina, L.A., and Gel’d, P.V., Silitsidy (The Silicides), Moscow: Metallurgiya, 1979.

Wang, X.H. and Zhou, Y.C., J. Mater. Sci. Technol., 2010, vol. 26, no. 5, p. 385.

Merzhanov, A.G., Tverdoplamennoe gorenie (Hard-Flame Combustion), Chernogolovka: Inst. Struct. Macrokin. Ross. Acad. Sci. (ISMAN), 2000.

Shulaev, V.M., Andreev, A.A., Stolbovoi, V.A., et al., Fiz. Inzh. Poverkhn., 2008, vol. 6, nos. 1–2, p. 105.

Mrochek, Zh.A., Eizner, B.A., and Ivanov, I.A., Elektron. Obrab. Mater., 1990, no. 1, p. 13.

Grigor’ev, S.N. and Voronin, N.A., Tekhnologiya vakuumno-plazmennoi obrabotki instrumenta i detalei mashin (Technology of Vacuum-Plasma Treatment of the Tool and Machine Elements), Moscow: Stankin, Yanus-K, 2005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.F. Fedotov, A.P. Amosov, A.A. Ermoshkin, V.N. Lavro, S.I. Altukhov, E.I. Latukhin, D.M. Davydov, 2013, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2013, No. 2, pp. 29–36.

About this article

Cite this article

Fedotov, A.F., Amosov, A.P., Ermoshkin, A.A. et al. Composition, structure, and properties of SHS-compacted cathodes of the Ti-C-Al-Si system and vacuum-arc coatings obtained from them. Russ. J. Non-ferrous Metals 55, 477–484 (2014). https://doi.org/10.3103/S1067821214050083

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821214050083