Abstract

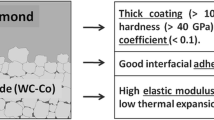

The current state of research on the use of CVD diamonds in diamond tools is reviewed. Features of single crystal and polycrystalline CVD diamonds and CVD diamond films are shown. Their comparative properties are given. Their structure and the peculiarities of processing their surfaces are shown. Technological features of the preparation of diamond tools with a working layer of CVD diamonds and the use of such tools are discussed. Samples of polycrystalline CVD diamonds for the dressing tool and features of their application in the dressing rollers are shown.

Similar content being viewed by others

REFERENCES

The Global Diamond Report. 2019. bain_report_global_diamond_report_2019.pdf.

Lab-Grown Diamond Industry—Statistics & Facts. https://www.statista.com/topics/7108/lab-grown-diamond-industry.

CVD Diamond Market. https://www. industryresearch.co/enquiry/request-sample/16690639.

Global CVD Diamond Market Size, Manufacturers, Supply Chain, Sales Channel and Clients, 2020–2026. www.360marketupdates.com/enquiry/request-sample/15950750.

Global CVD Diamond Market Growth 2020–2025. www.wiseguyreports.com/sample-request/5031536-global-cvd-diamond-market-growth-2020-2025.

www.drkaiser.com/fileadmin/user_upload/drkaiser_de/documents/RU/DR-KAISER.

Selivanova, A.G., 21st century—the era of the diamond, Instrum. Svit, 2005, no. 3, p. 18.

Spits, R., Review of recent large single crystal HPHT & CVD diamond synthesis developments, Proc. 2nd Int. Industrial Diamond Conf, 19–20 April, 2007, Rome, Italy.

Kvasnytsya, V.M. and Kvasnytsia, I.V., Cyclic twins of CVD diamond crystals, J. Superhard Mater., 2019, vol. 41, no. 6, pp. 369–376.

Vins, V.G., Yelisseyev, A.P., Smovzh, D.V., and Novopashin, S.A. Optical properties of CVD single crystal diamonds before and after different post-growth treatments, Diamond Relat. Mater., 2018, vol. 86, pp. 79–86.

Zaitsev, A.M., Kazuchits, N.M., Kazuchits, V.N., Moe, K.S., Rusetsky, M.S., Korolik, O.V., Kouki Kitajima, Butler, J.E., and Wang, W., Nitrogen-doped CVD diamond: Nitrogen concentration, color and internal stress, Diamond Relat. Mater., 2020, vol. 105, 107794.

Naamoun, M., Tallaire, A., Doppelt, P., Gicquel, A., Legros, M., Barjon, J., and Achard, J., Reduction of dislocation densities in single crystal CVD diamond by using self-assembled metallic masks, Diamond Relat. Mater., 2015, vol. 58, pp. 62–68.

Remes, Z., Nesladek, M., Tranchant, N., and Bogdan, G., Optical and electronic properties of freestanding single crystal CVD diamond, Proc. 2nd Int. Industrial Diamond Conf., 19–20 April, 2007, Rome, Italy.

Morse, J., Salomé, M., Berdermann, E., Pomorski, M., Cunningham, W., Grant, J., and O’Shea, V., Single crystal CVD diamond for synchrotron X-ray beam monitoring, Proc. 2nd Int. Industrial Diamond Conf. 19–20 April, 2007, Rome, Italy.

Liang, Q., Meng, Y.F., Yan, C.-S., Krasnicki, S., Lai, J., Hermawan, K., Shu, H., Popov, D., Yu, T., Yang, W., Mao, N.K., and Hemley, R.J., Development in synthesis, characterization, and application of large, high-quality CVD single crystal diamond, J. Superhard Mater., 2013, vol. 35, no. 4, pp. 195–213.

Hirmke, J., Schwarz, S., Hempel, F., Stancu, G.D., Ropcke, J., and Rosiwal, S., Diamond volume crystal growth in HF-CVD and monitoring gas phase with laser absorption spectroscopy, J. Superhard Mater., 2007, vol. 29, no. 3, pp. 133–137.

Zhang, T., Qin, F., Zhang, L., Gao, L., and Sun, F., HFCVD synthesis of boron-doped microcrystalline diamonds, J. Superhard Mater., 2019, vol. 41, no. 3, pp. 143–148.

Shul’zhenko, A.A., Ashkinazi, E.E., Ral’chenko, V.G., Sokolov, A.N., Aleksandrova, L.I., Gargin, V.G., Khomich, A.A., Vlasov, I.I., Bol’shakov, A.P., Zavedeev, E.V., Ryzhkov, S.G., Sobolev, S.S., and Konov, V.I., Hardness of single-crystal CVD diamond and phase transformations in it on indentation, J. Superhard Mater., 2014, vol. 36, no. 5, pp. 297–302.

https://www.marketsandmarkets.com/Market-Reports/diamond-coating-market-255400901.html.

Yang, M., Bai, S., Xu, Q., Li, J., Shimada, T., Li, Q., Goto, T., Tu, R., and Zhang, S., Mechanical properties of high-crystalline diamond films grown via laser MPCVD, Diamond Relat. Mater., 2020, vol. 109, 108094.

Deng, B., Wei, Q., Yi, M., Luo, Y., Li, L., Zhou, K., and Ma, L., Coupling effects of CH4/H2/Ar gas ratios and hot filament-substrate distance on the growth of nanocrystalline diamond, J. Superhard Mater., 2020, vol. 42, no. 3, pp. 157–164.

Deng, F., Hao, C., Guo, Z., Wang, S., Bo, X., and Zhao, Z., Effects of carbonization of filaments on CVD diamond thick films prepared by HFCVD method, J. Superhard Mater., 2020, vol. 42, no. 5, pp. 287–293.

Din, S.H., Shah, M.A., and Sheikh, N.A., Tribological performance of titanium alloy Ti–6Al–4V via CVD-diamond coatings, J. Superhard Mater., 2018, vol. 40, no. 1, pp. 26–39.

Dejun, K., Wen, Z., and Ling, Z., Friction-wear behaviors of chemical vapor deposited diamond films at high temperatures, J. Superhard Mater., 2019, vol. 41, no. 2, pp. 98–105.

Ralchenko, V., Nistor, L., Pleuler, E., Khomich, A., Vlasov, I., and Khmelnitskii, R., Structure and properties of high-temperature annealed CVD diamond, Diamond Relat. Mater., 2003, vol. 12, nos. 10–11, pp. 1964–1970.

Ral’chenko, V.G. and Ashkinazi, E.E., Synthesis conditions, abrasive and laser treatment of polycrystalline CVD diamond, Instrum. Svit, 2005, no. 3, pp. 14–18.

Meng, D., Yue, W., Lin, F., Wang, C., and Wu, Z., Thermal stability of ultrahard polycrystalline diamond composite materials, J. Superhard Mater., 2015, vol. 37, no. 2, pp. 67–72.

Ashkinazi, E.E., Shul’zhenko, A.A., Gargin, V.G., Sokolov, A.N., Aleksandrova, L.I., Tkach, V.N., Ral’chenko, V.G., Konov, V.I., Bol’shakov, A.P., Ryzhkov, S.G., Bogdanov, R.K., Zakora, A.P., and Suprun, M.V., Diamond polycrystalline composite material with dispersion-hardened nickel-based additive, J. Superhard Mater., 2013, vol. 35, no. 5, pp. 327–329.

Sokolov, A.N., Shul’zhenko, A.A., Gargin, V.G., Kotko, A.V., Briksa, V.P., Bogdanov, P.K., Zakora, A.P., Loshak, M.G., and Aleksandrova, L.I., Structure and physico-mechanical properties of CVD diamonds of various crystalline perfections in the hybridite material, J. Superhard Mater., 2013, vol. 35, no. 2, pp. 83–92.

Novikov, M.V., Shul’zhenko, O.O., and Gargin, V.G., Ukraine Patent 83326, Byull., 2013, no. 17.

Hitoshi, S. and Irifune, T., Formation mechanism and some properties of superhard nanopolycrystalline diamond synthesyzed by direct conversion sintering, J. Jpn. Soc. Powder Powder Metall., 2006, vol. 53, no. 5, pp. 452–458.

Frushou, R.H. and Li, W., US Patent Application 20030230232, 2003.

Russel, J. H., Ho-Kwang, M., and Chih-Shiue, Y., US Patent 7115241, 2006.

Firstov, S.A. and Rogul’, T.G., Theoretical (limiting) strength, Dokl. Akad. Nauk Ukr., 2007, no. 4, pp. 110–114.

Shul’zhenko, A.A., Ashkinazi, E.E., Sokolov, A.N., Gargin, V.G., Ral’chenko, V.G., Konov, V.I., Aleksandrova, L.I., Bogdanov, R.K., Zakora, A.P., Vlasov, I.I., Artyukov, I.A., and Petronyuk, Yu.S., Novel hybrid ultrahard material, J. Superhard Mater., 2010, vol. 32, no. 5, pp. 293–300.

Shul’zhenko, A.A., Sokolov, A.N., Aleksandrova, L.I., Gargin, V.G., Osipov, A.S., Stasyuk, L.F., Zakora, A.P., Bogdanov, R.K., Il’nitskaya, G.D., Suprun, M.V., Tkach, V.N., and Rusinova, N.A., Hybrid diamond carbide insert, in Porodorazrushayushchii i metalloobrabatyvayushchii instrument – tekhnika i tekhnologiya ego izgotovleniya i primeneniya: Sb. nauch. tr. (Rock Cutting and Metalworking Tools—Technique and Technology of Its Manufacture and Application: Collection of Scientific Works), 2014, vol. 17, pp. 232–240.

CVD Diamond for Dressing Tools. http://www.hediamond.cn/en/product/25.html.

Element Six Abrasives Treasury Limited Trademarks (13 Records). https://www.trademarkia.com/company-element-six-abrasives-treasury-limited-3904510-page-1-2.

Ergs, T., Müller, U., Vits, F., and Barth, S., Tribological conditions in grinding of polycrystalline diamond, Diamond Relat. Mater., 2020, vol. 108, 107930.

Yang, N., Zong, W., Li, Z., and Sun, T., Wear process of single crystal diamond affected by sliding velocity and contact pressure in mechanical polishing, Diamond Relat. Mater., 2015, vol. 58, pp. 46–53.

Wheeler, D.W. and Wood, R.J.K., High velocity erosion of CVD diamond coatings by diamond particles, Diamond Relat. Mater., 2018, vol. 84, pp. 32–40.

Zhao, G., Li, Z., Hu, M., He, N., and Jamil, M., Fabrication and performance of CVD diamond cutting tool in micro milling of oxygen-free copper, Diamond Relat. Mater., 2019, vol. 100, 107589.

Dojo, H., Tabata, T., Endo, K., Yamada, H., Chayahara, A., Mokuno, Y., and Yamamura, K., Planarization and smoothing of CVD grown diamond wafer by atmospheric pressure plasma based process, Proc. 6th Int. Conf. of Asian Society for Precision Engineering and Nanotechnology (ASPEN2015), 15–20 August, 2015, Harbin, China.

Xu, H., Zang, J., Yang, G., Jia, S., Tian, P., Zhang, Y., Wang, Y., Yu, Y., Lu, J., Xu, X., and Zhang, P., High-efficiency grinding CVD diamond films by Fe-Ce containing corundum grinding wheels. Diamond Relat. Mater., 2017, vol. 80, pp. 5–13.

Semba, T., Amamoto, Y., and Fujiyama, H., Reactive ion etching of microgrinding tool made of polycrystalline diamond, Proc. 6th Int. Conf. of Asian Society for Precision Engineering and Nanotechnology (ASPEN2015), 15–20 August, 2015, Harbin, China.

Gäbler, J., Pleger, S., and Schäfer, L., CVD diamond layers with a controlled roughness enable high-precision and micro grinding tools, Proc. 2nd Int. Industrial Diamond Conf., 19–20 April, 2007, Rome, Italy.

Nozhkina, A.V., Kostikov, V.I., Ral’chenko, V.G., Stopareva, N.N., Razbegaev, A.Yu., Kataeva, E.R., and Zavedeev, E.A., Machining of diamond single crystals with coated diamond powders, in Porodorazrushayushchii i metalloobrabatyvayushchii instrument – tekhnika i tekhnologiya ego izgotovleniya i primeneniya: Sb. nauch. tr. (Rock Cutting and Metalworking Tools—Technique and Technology of Its Manufacture and Application: Collection of Scientific Works), Kyiv: Bakul Inst. Superhard Mater., 2018, vol. 21, pp. 315–324.

Pyzhov, I.N., Fedorovich, V.A., Ryazanova-Khitrovskaya, N.V., Kryukova, N.V., and Klimenko, V.G., Some approaches to increase the service life of diamond pencils, Suchasni Technol. Mashinobuduv. 2014, vol. 9, pp. 134–141.

Pashchenko, E.O., Ryabchenko, S.V., and Kukharenko, S.A., in Modern Issues of Production and Repair in Industry and Transport: Proceedings of 20th International Scientific and Technical Workshop, March 23–28, 2020, Tbilisi. Kyiv: ATM Ukraine, 2020, pp. 133–135.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares that he has no conflicts of interests.

Additional information

Translated by O. Kadkin

About this article

Cite this article

Lavrinenko, V.I. CVD Diamonds in Diamond Tools: Features and Properties, Peculiarities of Processing, and Application in Modern Diamond Tools (Review). J. Superhard Mater. 44, 431–449 (2022). https://doi.org/10.3103/S1063457622060077

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457622060077