Abstract

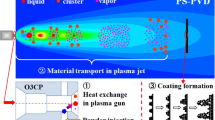

The paper describes the main design principles of plasma-enhanced chemical vapor deposition (PECVD) equipment based on a Mod. VUP-5(M) universal vacuum pumping station, and the application of such equipment for deposition of thin films, including nanolayered ones, from vapors of usually liquid precursors. The method can be classified as PECVD in a gas atmosphere activated by E-type radio-frequency (RF) plasma in continuous flow systems (the open-tube method). The equipment is universal in terms of the types of precursors to be used and has a sufficient set of process variable in order to provide deposition of a wide range of coatings with a controlled thickness from 1 to 2000 nm. The PECVD equipment favorably supplements the VUP-5(M) functionalities and extends performance without any significant alteration of its design.

Similar content being viewed by others

References

ALD-UKRAINE 2017. HERALD Training School, Kyiv, Ukraine, 30 May–1 June 2017.

Azarenkov, N.A., Beresnev, V.M., Pogrebnyak, A.D., et al., Nanomaterialy, nanopokrytiya, nanotekhnologii. Ucheb. pos. (Nanomaterials, Nanocoatings, Nanotechnologies. Educational Manual), Kharkov: V.N. Karazin KhNU, 2009.

Shpak, A.P., Maiboroda, V.P., Kunitskii, Yu.A., and Revo, S.L., Nanosloistye kompozitsionnye materialy i pokrytiya (Nanolayered Composite Materials and Coatings), Kiev: Akademperiodika, 2004.

Porada, O.K., The Influence of Deposition Conditions for Si-C-N and Ti-N-C PECVD Coatings on the Structure Formation and Properties of the Coatings, Cand. Sci. (Eng.) Dissertation, Kyiv, 2009.

Blinkov, I.V. and Volkhonskii, A.O., Multisloinye nanostrukturnye pokrytiya dlya rezhushchego instrumenta (Multilayered Nonostructured Coatings for Cutting Tools), Moscow: Lambert Academic Publishing, 2012.

Hamakawa, Y., Amorphous Semiconductor Technologies and Devices, Tokyo: Ohmsha, Ltd., 1983.

Joannopoulos, J.D. and Lukovsky, G. (Eds.), The Physics of Hydrogenated Amorphous Silicon. Volume I. Structure, Preparation, and Devices. Volume II. Electronic and Vibrational Properties, Springer-Verlag Berlin Heidelberg, 1984.

Madan, A. and Shaw, M.P., The Physics and Applications of Amorphous Semiconductors, Academic Press, 1988.

Uvarova, I.V., Maksimenko, V.B., and Yarmola, T.M., Nanomaterialy ta yikh vykorystannya u medychnykh vyrobakh. Navchal’n. pos. MMIF NTUU “KPI” (Nanomaterials and Their Applications in Medical Products. Educational Manual. Biomedical Engineering Department. National Technical University of Ukraine “KPI”), Kyiv: KIM, 2013.

Uvarova, I.V. and Maksimenko, V.B., Biosumisni materialy dlya medychnykh vyrobiv. Navchal’n. pos. MMIF NTUU “KPI” (Biocompatible Materials for Medical Products. Educational Manual. Biomedical Engineering Department. National Technical University of Ukraine “KPI”), Kyiv: KIM, 2013.

Park, J.H. and Sudarshan, T.S., Surface engineering series, in Chemical vapour deposition, Ohio, USA: ASM International, Materials Park, 2001, Volume 2.

Jones, A.C. and Hitchman, M.L. (Eds.), Chemical Vapour Deposition: Precursors, Processes and Applications, Cambridge, UK: Royal Society of Chemistry, 2009.

Mazurenko, Ye.A., Mazurenko, Ye.A., Gerasymchuk, A.I., and Ovsyannykov, V.P., Chemical vapor dposition, synthesis of functional materials (Review), Fiz. Khim. Tverd. Tila, 2001, vol. 2, no. 3, pp. 339–349.

Timoshenko, N.I. and Rebrov, A.K., How to produce nanostructured films and coatings from a gaseous phase. Review. URL: http://www.itp.nsc.ru/articles/populjarno_o_nanotehnologijah.html

Danilin, B.S. and Syrchin, V.K., Magnetronnye raspylitel’nye sistemy (Magnetron Sputtering Systems), Moscow: Radio i Svyaz’, 1982.

Kelly, P.J. and Arnell, R.D., Magnetron sputtering: a review of recent developments and applications, Vacuum, 2000, vol. 56, pp. 159–172.

Jedrzejowski, P., Cizek, J., Amassian, A., Klemberg-Sapieha, J.E., Vlcek, J., and Martinu, L., Mechanical and optical properties of hard SiCN coatings prepared by PECVD, Thin Solid Films, 2004, vol. 447–448, pp. 201–207.

Ferreira, I., Fortunato, E., Vilarinho, P., Viana, A. S., Ramos, A.R., Alves, E., Martins, R., Hydrogenated silicon carbon nitride films obtained by HWCVD, PA-HWCVD and PECVD techniques, J. Non-Cryst. Solids, 2006, vol. 352, pp. 1361–1366.

Huran, J., Valovic, A., Kucer, M., Kleinová, A., Kovaccová, E., Bohácek, P., and Sekácová, M., Hydrogenated silicon carbon nitride films prepared by PECVD technology: properties, J. Electrical Eng, 2012, vol. 63, pp. 333–335.

Post vakuumnyi universal’nyi VUP-5 (dokumentatsiya po ekspluatatsii) (Universal Vacuum Pumping Station VUP-5 (Operating Manual)), 1990.

Plazmokhmicheskoe osazhdenie (PECVD). Peredovye plazmennye tekhnologii (Plasma-Enhanced Chemical Vapor Deposition (PECVD). Advanced Plasma Technologies. URL: http://www.plasmasystem.ru/technology/pecvd

Ivashchenko, L.A., Ivashchenko, V.I., Porada, O.K., Butenko, O.O., Dub, S.M., Lytvyn, P.M., Morozhenko, V.O., and Kozak, A.O., Characterization of PECVD coatings deposited using hexamethyl-disilazane, Nanostr. Materialoved., 2011, vol. 4, pp. 42–48.

Ivashchenko, V.I., Kozak, A.O., Ivashchenko, L.A., Sinelnichenko, O.K., Lytvyn, O.S., Tomila, T.V., and Malakhov, V.J., Characterization of SiCN thin films: experimental and theoretical investigations, Thin Solid Films, 2014, vol. 569, pp. 57–63.

Porada, O.K., The influence of bias potential on the properties of Si-C-N films deposited on silicon by PECVD technique from hexamethyl-disilazane, Nanostr. Materialoved., 2014, no. 3–4, pp. 3–14.

Porada, O.K., The influence of deposition and annealing conditions on nanohardness of amorphous Si-C-N films, Nanosis., Manomat., Nanotekhn., 2015, vol. 13, no. 1, pp. 59–74

Porada, O.K., Manzhara, V.S., Kozak, A.O., Ivashchenko, V.I., and Ivashchenko, L.A., Pholuminescent properties of PECVD films based on Si, C, N, Zhurn. Nano- ta Elektr. Fiz., 2017, vol. 9, no. 2, pp. 02022 (6).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Porada, O.K., Ivashchenko, V.I., Ivashchenko, L.A. et al. Plasma-Enhanced CVD Equipment for Deposition of Nanocomposite Nanolayered Films. J. Superhard Mater. 41, 32–37 (2019). https://doi.org/10.3103/S1063457619010040

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457619010040