Abstract

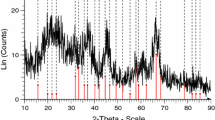

Lithium aluminate samples were obtained in reactions of solution combustion synthesis (SCS) with various types of fuel (glycine, leucine, and urea) from aluminum and lithium nitrate solutions. The simultaneous thermal analysis (STA) of precursors obtained in conditions of fuel and oxidizer stoichiometry showed the presence of impurities due to incomplete decomposition of initial salts containing carbon fragments of fuel and nitrate groups. An exception was the precursor from the dual-fuel SCS reaction, φ (glycine : urea) = 1 : 3, in which pure γ-LiAlO2 powder was formed. Replacement of lithium nitrate with lithium carbonate was found to reduce the process temperature and the relative amount of organic fuel. As a result, the content of carbon fragments in the precursor significantly decreased after synthesis.

Similar content being viewed by others

REFERENCES

Nishikawa, M., Baba, A., and Kawamur, Y., Tritium inventory in a LiAlO2 blanket, J. Nucl. Mater., 1997, vol. 246, pp. 1–8. https://doi.org/10.1016/S0022-3115(97)00091-3

Ha, N.T., Giap, T.V., and Thanh, N.T., Synthesis of lithium aluminate for application in radiation dosimetry, Mater. Lett., 2020, vol. 267, p. 127506. https://doi.org/10.1016/j.matlet.2020.127506

Appetecchi, G.B., Dautzenberg, G., and Scrosati, B., A new class of advanced polymer electrolytes and their relevance in plastic-like, rechargeable lithium batteries, J. Electrochem. Soc., 1996, vol. 143, no. 1, pp. 6–12. https://doi.org/10.1149/1.1836379

Patil, K.Y., Yoon, S.P., Han, J., Lim, T.H., Nam, S.W., and Oh, I.H., The effect of lithium addition on aluminum-reinforced α-LiAlO2 matrices for molten carbonate fuel cells, Int. J. Hydrog. Energy, 2011, vol. 36, pp. 6237–6247. https://doi.org/10.1016/j.ijhydene.2011.01.161

Terada, S., Nagashima, I., Higaki, K., and Ito, Y., Stability of LiAlO2 as electrolyte matrix for molten carbonate fuel cells, J. Power Sources, 1998, vol. 75, no. 2, pp. 223–229. https://doi.org/10.1016/S0378-7753(98)00115-3

Fang, Z-K., Zhu, Y-R., Yi, T-F., and Xie, Y., A novel Li4Ti5O8–LiAlO2 composite as high-performance anode material for litium-ion battery, ACS Sustainable Chem. Eng., 2016, vol. 4, no. 4, pp. 1994–2003. https://doi.org/10.1021/acssuschemeng.5b01271

Zou, Ch., Yang, L., Zang, Z., Tao, X., Yi, L., Chen, X., Liu, X., Zhang, X., and Wang, X., LiAlO2-coated LiNi0.8Co0.1Mn0.1O2 and chlorine-rich argyrodite enabling high-performance all-solid-state lithium batteries at suitable stack pressure, Ceram. Int., 2023, vol. 49, no. 1, pp. 443–449. https://doi.org/10.1016/j.ceramint.2022.09.010

Tang, W., Chen, Z., Huang, H., Irfan, M., Huang, C., Yang, Z., and Zhang, W., PVP-bridged γ-LiAlO2 nanolayer on Li1.2Ni0.182Co0.08Mn0.538O2 cathode materials for improving the rate capability and cycling stability, Chem. Eng. Sci., 2021, vol. 229, pp. 116–126. https://doi.org/10.1016/j.ces.2020.116126

Deganello, F. and Tyagi, A.K., Solution combustion synthesis, energy and environment: best parameters for better materials. Prog. Cryst. Growth Charact. Mater., 2018, vol. 64, pp. 23–61. https://doi.org/10.1016/j.pcrysgrow.2018.03.001

Varma, A., Mukasyan, A.S., Rogachev, A.S., and Manukyan, K.V., Solution combustion synthesis of nanoscale materials, Chem. Rev., 2016, vol. 116, pp. 14493−14586. https://doi.org/10.1021/acs.chemrev.6b00279

Wen, Z., Gu, Z., Xu, X., and Zhu, X., Research on the preparation, electrical and mechanical properties of γ-LiAlO2 ceramics, J. Nucl. Mater., 2004, vols. 329–333, pp. 1283–1286. https://doi.org/10.1016/j.jnucmat.2004.04.230

Li, F., Hu, K., Li, J., Zhang, D., and Chen, G., Combustion synthesis of γ-lithium aluminate by using various fuels, J. Nucl. Mater., 2002, vol. 300, pp. 82–88. https://doi.org/10.1016/S0022-3115(01)00710-3

Kwon, S.W., Park, S.B., Seo, G., and Hwang, S.T., Preparation of lithium aluminate via polymeric precursor routes, J. Nucl. Mater., 1998, vol. 257, pp. 172–179. https://doi.org/10.1016/S0022-3115(98)00442-5

Zhuravlev, V.D., Ermakova, L.V., Patrusheva, T.A., and Bamburov, V.G., Influence of fuel on the SCS temperature of lithium aluminate, Int. J. Self-Propag. High-Temp. Synth., 2022, vol. 31, no. 4, pp. 253–260. https://doi.org/10.3103/S1061386222050089

Zhuravlev, V.D., Vasil’ev, V.G., Vladimirova, E.V., Shevchenko, V.G., Grigorov, I.G., Bamburov, V.G., Beketov, A.P., and Baranov, M.V., Glycine–nitrate combustion synthesis of finely dispersed alumina, Glass Phys. Chem., 2010, vol. 36, no. 4, pp. 506–512. https://doi.org/10.1134/S1087659610040164

Aisawa, S., Sasaki, S., Takahashi, S., Hirahara, H., Nakayama, H., and Narita, E.I., Intercalation of amino acids and oligopeptides into Zn–Al layered double hydroxide by coprecipitation reaction, J. Phys. Chem. Solids, 2006, vol. 67, pp. 920–925. https://doi.org/10.1016/j.jpcs.2006.01.004

Khaliullin, Sh.M., Zhuravlev, V.D., Bamburov, V.G., Khort, A.A., Roslyakov, S.I., Trusov, G.V., and Moskovskikh, D.O., Effect of the residual water content in gels on solution combustion synthesis temperature, J. Sol–Gel Sci. Technol., 2020, vol. 93, pp. 251–261. https://doi.org/10.1007/s10971-019-05189-8

Ribeiro, R.A., Silva, G.G., and Mohallem, N.D.S., The influences of heat treatment on the structural properties of lithium aluminates, J. Phys. Chem. Solids, 2001, vol. 62, pp. 857–864. https://doi.org/10.1016/S0022-3697(00)00239-0

Funding

The studies were carried out within the State Assignment and R&D plans of the Institute of Solid State Chemistry, Ural Branch, Russian Academy of Sciences, project no. AAAA-A19-119031890026-6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Zhuravlev, V.D., Reznitskikh, O.G., Ermakova, L.V. et al. Simultaneous Thermal Analysis of Lithium Aluminate SCS-Precursors Produced with Different Fuels. Int. J Self-Propag. High-Temp. Synth. 32, 208–214 (2023). https://doi.org/10.3103/S1061386223030111

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1061386223030111