Abstract

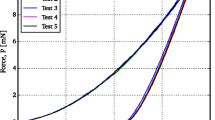

A qualitative analysis of the experimental indentation diagrams for topocomposites has been conducted. These diagrams are unloading curves with linear and nonlinear sections at the end of the unloading curve and characterize the interfacial delamination along the coating–substrate interface. It has been shown that the exfoliation in both topocomposites results in a linear relationship between the load and the indentation depth. The width of the hysteresis loops confirms the higher damping capacity of an aluminum nitride coating as compared with a titanium nitride coating. The relevance of studying the effect of the coating structure on the deformation behavior and damage to topocomposites at high contact pressures is shown.

Similar content being viewed by others

REFERENCES

Golovin, Yu.I., Nanoindentirovanie i ego vozmozhnosti (Nanoindentation and Its Capabilities), Moscow: Mashinostroenie, 2009.

Bhushan, B., Depth-sensing nanoindentation measurement techniques and applications, Microsyst. Technol., 2017, vol. 23, pp. 1595–1649. https://doi.org/10.1007/s00542-017-3372-2

Chen, J., Lin, Z., Bull, S.J., Phillips, C.L., and Bristowe, P.D., Experimental and modelling techniques for assessing the adhesion of very thin coatings on glass, J. Phys. D: Appl. Phys., 2009, vol. 42, p. 214003. https://doi.org/10.1088/0022-3727/42/21/214003

Abdul-Baqi, A. and Van der Giessen, E., Delamination of a strong film from a ductile substrate during indentation unloading, J. Mater. Res., 2001, vol. 16, no. 5, pp. 1396–1407. https://doi.org/10.1557/JMR.2001.0195

Lu, M., Xie, H., and Huang, H., Characterization of interfacial adhesion of thin film/substrate systems using indentation-induced delamination: a focused review, Key Eng. Mater., 2013, vol. 533, pp. 201–222. https://doi.org/10.4028/www.scientific.net/KEM.533.201

Lu, M. and Huang, H., Interfacial energy release rates of SiN/GaAs film/substrate systems determined using a cyclic loading dual-indentation method, Thin Solid Films, 2015, vol. 589, pp. 822–830. https://doi.org/10.1016/j.tsf.2015.07.027

Ruiz, G., Pandolfi, A., and Ortiz, M., Three-dimensional cohesive modeling of dynamic mixed-mode fracture, Int. J. Numer. Methods Eng., 2001, vol. 52, nos. 1–2, pp. 97–120. https://doi.org/10.1002/nme.273

Hu, J., Chou, Y.K., and Thompson, R.G., Cohesive zone effects on coating failure evaluations of diamond-coated tools, Surf. Coat. Technol., 2008, vol. 203, nos. 5–7, pp. 730–735. https://doi.org/10.1016/j.surfcoat.2008.08.029

Voronin, N.A., Modeling of an indentation diagram for topocomposites, J. Mach. Manuf. Reliab., 2018, vol. 47, no. 5, pp. 434–441. https://doi.org/10.3103/S1052618818050138

Voronin, N.A., Effect of substrate material compliance on the character of topocomposite damage under instrumental indentation, J. Mach. Manuf. Reliab., 2020, vol. 49, no. 10, pp. 862–869. https://doi.org/10.3103/S1052618820100118

Oleinik, G.S., Structural mechanisms of plastic deformation of ceramics, Elektron. Mikroskopiya Prochnost’ Mater., 2014, no. 20, pp. 3–30. http://dspace.nbuv.gov.ua/handle/123456789/114278.

Shtanskii, D.V., Kulinich, S.L., Levashov, E.L., and Moore, J.J., Structure and physical-mechanical properties of nanostructured thin films, Phys. Solid State, 2003, vol. 45, no. 6, pp. 1177–1184. https://doi.org/10.1134/1.1583811

ACKNOWLEDGMENTS

The author is grateful to the researcher K.S. Kravchuk for obtaining experimental indentation diagrams and displaying the images of indents.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares that he has no conflicts of interest.

Additional information

Translated by N. Podymova

About this article

Cite this article

Voronin, N.A. Phenomenological Analysis of Indentation Diagrams for Topocomposites on a Compliant Substrate. J. Mach. Manuf. Reliab. 51, 86–93 (2022). https://doi.org/10.3103/S1052618822010113

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618822010113