Abstract

The structure, the chemical and phase compositions, and the micromechanical and tribological properties of chromium–carbon coatings obtained by the magnetron sputtering of composite and/or sintered chromium–nanodiamond targets are investigated. The coatings possess the composite multiphase structure composed of chromium and its phases formed as a result of the chemical interactions of the target material’s components both between each other and with the reactive gas if present in a sputtering atmosphere. Several technological factors influencing the structural and phase peculiarities of the coatings, their nanohardness, and the dry friction behavior at high contact pressures are studied.

Similar content being viewed by others

References

Dolmatov, V.Yu., Detonation synthesis ultradispersed diamonds: properties and applications, Russ. Chem. Rev., 2001, vol. 70, no. 7, pp. 607–626.

Dolmatov, V.Yu., Detonation-synthesis nanodiamonds: synthesis, structure, properties and applications, Russ. Chem. Rev., 2007, vol. 76, no. 4, pp. 339–360.

Nanoalmazy detonatsionnogo sinteza: Poluchenie i primenenie (Detonation-Synthesis Nanodiamonds, Production and Application), Vityaz, P.A., Ed., Minsk: Belarus. Navuka, 2013.

Andreev, M.A., Chekan, V.A., Markova, L.V., and Kuznetsova, T.A., Atomic force microscopy as a method for studying the structure of thin ion-beam coatings based on chromium, in Tr. 4-i Belorusskogo seminara po skaniruyushchei zondovoi mikroskopii (Proceedings of the 4th Belorussian Seminar on Scanning Probe Microscopy), Gomel’: MPRI, 2000, pp. 60–63.

Gassner, G., Mayerhofer, P.H., Mitterer, C., and Kiefer, J., Structure-property relations in Cr-C/a-C: H coatings deposited by reactive magnetron sputtering, Surf. Coat. Technol., 2005, vol. 200, pp. 1147–1150.

Khrushchov, M.M., Alloyed diamond-like coatings of tribotechnical designation, in Sovremennye tekhnologii modifitsirovaniya poverkhnostei detalei mashin (Modern Technologies for Machine Elements Surface Modification), Moskvitin, G.V, Ed., Moscow: LENAND, 2013, pp. 78–113.

Atamanov, M.V., Dubravina, A.A., Levin, I.S., Marchenko, E.A., and Khrushchov, M.M., Composition, structure and tribological properties of chromium doped diamond-like coatings, Probl. Mashinostr. Avtomatiz., 2013, no. 3, pp. 102–105.

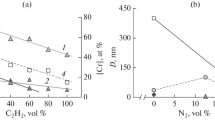

Khrushchov, M.M., Atamanov, M.V., Marchenko, E.A., Levin, I.S., Dubravina, A.A., and Petrzhik, M.I., Diamond-like carbon coatings with nanocomposite structure formed by reactive magnetron sputtering of chrome in an Ar + C2H2 + N2 gas mixture and their tribological behavior, J. Mach. Manuf. Reliab., 2014, vol. 43, no. 1, pp. 29–35.

Khrushchov, M.M., Marchenko, E.A., Atamanov, M.V., Levin, I.S., and Tarelkin, Yu.A., Effect of active gas mixture composition on tribological behavior of coatings obtained by reactive magnetron sputtering of chromium in acetylene–nitrogen and acetylene–air gas mixtures, J. Frict. Wear, 2016, vol. 37, no. 1, pp. 407–414.

Iveronova, V.I. and Revkevich, G.P., Teoriya rasseyaniya rentgenovskikh luchei (Theory of X-Ray Scattering), Moscow: Moscow Univ. Publishers, 1978.

Kombalov, V.S., Metody i sredstva ispytanii na trenie i iznos konstruktsionnykh i smazochnykh materialov: Spravochnik (Methods and Means for Testing the Friction and Wear of Engineering Materials and Lubricants, The Handbook), Frolov, K.V. and Marchenko, E.A., Ed., Moscow: Mashinostroenie, 2008.

Metodika raschetnoi otsenki iznosostoikosti poverkhnostei treniya detalei mashin (Calculation Method of the Wear Resistance of Friction Surfaces of Machine Parts), Moscow: Izd-vo Standartov, 1979.

Metody i sredstva uprochneniya poverkhnostei detalei mashin kontsentrirovannymi potokami energii (Methods and Means for the Surface Hardening of Machine Elements Using High-Energy Fluxes), Gusenkov, A.P., Ed., Moscow: Nauka, 1992.

Bakai, A.S., Zhukov, A.I., and Sleptsov, S.N., Densification of growing films by ion beams, J. Phys.: Condens. Matter, 1999, vol. 11, no. 29, pp. 5681–5690.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.M. Khrushchov, M.V. Atamanov, N.V. Shevchenko, E.A. Marchenko, I.S. Levin, M.I. Petrzhik, V.I. Miroshnichenko, O.S. Antonova, M.D. Reilyanu, 2018, published in Problemy Mashinostroeniya i Nadezhnosti Mashin, 2018, No. 2, pp. 44–53.

About this article

Cite this article

Khrushchov, M.M., Atamanov, M.V., Shevchenko, N.V. et al. Chromium and Detonation Nanodiamond Based Coatings of the Chromium–Carbon System: Deposition by Magnetron Sputtering, Peculiarities of Phase Composition, and Tribological Properties. J. Mach. Manuf. Reliab. 47, 160–167 (2018). https://doi.org/10.3103/S105261881802005X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S105261881802005X