Abstract—

It is noted that intellectual operations are significantly automated in the design of new materials (especially metamaterials, smart materials, composites), new products, structures, technological operations (including additive manufacturing), and therefore the role of specialists in the field of mechanics of solids (MoS) has changed significantly. It became possible to fully automate the process of solving differential equations that describe the formulation of the problem, including related ones. This is done using the Engineering Analysis Package (CAE) or combinations thereof. The calculator, designer, researcher sets the design (its CAD model) and external forces (boundary conditions in terms of MoS), description of materials (constitutive relations in terms of MoS), and the calculation is automatically performed.

It is noted that, in particular, the formulation of mechanical and mathematical formulations for new types of problems (preloading, interdisciplinary problems) remains in demand; construction of constitutive relations (material models) for new materials (composites, metamaterials, smart materials) and models using additional relations for their subsequent implementation in the CAE. It is also in demand to find exact solutions for the validation of the CAE.

On the example of the theory of multiple superimposition of large deformations and the implementation of this theory and its accompanying results in the industrial full-featured Fidesys package, the possibility of implementing the results of MoS for industry is demonstrated.

Similar content being viewed by others

REFERENCES

A. B. Kaplun, E. M. Morozov, and M. A. Olferieva, Ansys in the Hands of Engineers (Editorial URSS, Moscow, 2004) [in Russian].

E. M. Morozov, V. A. Levin, and A. V. Vershinin, Strength Analysis: FIDESYS in the Hands of Engineers (URSS, Moscow, 2015) [in Russian].

O. C. Zienkiewicz and R. L. Taylor, The Finite Element Method, Vol. 1: The Basis (Butterworth–Heinemann, London, 2000).

O. C. Zienkiewicz and R. L. Taylor, The Finite Element Method, Vol. 2: Solid Mechanics (Butterworth–Heinemann, London, 2000).

O. C. Zienkiewicz, R. L. Taylor, S. J. Sherwin, and J. Peiro´, “On discontinuous Galerkin methods,” Int. J. Numer. Meth. Eng. 58 (8), 1119–1148 (2003). https://doi.org/10.1002/nme.884

O. C. Zienkiewicz and R. L. Taylor, The Finite Element Method for Solid and Structural Mechanics (Elsevier, Amsterdam, 2005).

O. C. Zienkiewicz, R. L. Taylor, and J. Z. Zhu, The Finite Element Method: its Basis and Fundamentals (Elsevier, Amsterdam, 2005).

V. A. Levin and A. V. Vershinin, Nonlinear Computational Mechanics of Strength, Vol. 2: Numerical Methods. Implementation on High-Speed Computational Systems (Fizmatlit, Moscow, 2015) [in Russian].

D. M. Klimov and V. A. Rudenko, Methods of Computer Algebra in Problems of Mechanics (Nauka, Moscow, 1989) [in Russian].

V. A. Levin, “Using the method of successive approximations in problems of superposition of finite deformations,” Sov. Appl. Mech. 23, 472–476 (1987). https://doi.org/10.1007/BF00888060

V. A. Levin, K. M. Zingerman, and E. P. Sanchenko, On the Use of Numerical and Analytical Calculations on a Computer to Assess the Effects of the Third Order in the Problem of the Formation of Holes in an Elastic Body with Initial Deformations, Availble from VINITI, No. 7993–B87 (TPI, 1987).

V. A. Levin and K. M. Zingerman, “On one possibility of using methods of analytical calculations on computers in application to the problems of the theory of imposition of finite deformations,” in Mechanics of Elastomers (KPI, Krasnodar, 1987), pp. 28–35.

V. A. Levin and K. M. Vershinin, Nonlinear Computational Mechanics of Strength, Vol. 3: Exact and Approximate Analytical Solutions for Finite Deformations and Their Imposition (Fizmatlit, Moscow, 2016) [in Russian].

V. A. Levin, L.M. Zubov, and K. M. Zingerman, “Influence of the prestressed layer on the nonlinear flexure of a rectangular beam made of compressible material,” Dokl. Phys. 60, 167–170 (2015). https://doi.org/10.1134/S1028335815040023

V. A. Levin, L.M. Zubov, and K. M. Zingerman, “Multiple joined prestressed orthotropic layers under large strains,” Int. J. Eng Sci. 133, 47-59 (2018). https://doi.org/10.1016/j.ijengsci.2018.08.008

R. S. Rivlin, “A note on the torsion of an incompressible, highly-elastic cylinder,” Proc. Cambrige Phys. Soc. 45 (3), 485–487 (1949). https://doi.org/10.1017/S0305004100025135

R. S. Rivlin, “Large elastic deformations of isotropic materials. IV. Further developments of the general theory,” Philos. Trans. R. Soc. Lond. Ser. A. Math. Phys. Sci. 241 (835), 379–397 (1948). https://doi.org/10.1098/rsta.1948.0024

R. S. Rivlin, “Large elastic deformations of isotropic materials. V. The problem of flexture,” Proc. Royal Soc. Ser A. Math Phys Sci. 195 (1043), 463–473 (1949). https://doi.org/10.1098/rspa.1949.0004

R. S. Rivlin, “Large elastic deformations of isotropic materials. VI. Further results in the theory torsion, shear and flexture,” Philos. Trans. Royal Soc. Ser A. Math. Phys. Sci. 242 (845), 173–195 (1949). https://doi.org/10.1098/rsta.1949.0009

J. L. Ericksen, “Deformations possible in every isotropic, incompressible, perfectly elastic body,” ZAMP 5, 466–489 (1954). https://doi.org/10.1007/BF01601214

A. E. Green and R. T. Shield, “Finite extension and torsion of cylinders,” Philos. Trans. Royal Soc. Ser A. Math. Phys. Sci. 224 (846), 47–86 (1951). https://doi.org/10.1098/rsta.1951.0015

V. A. Levin, Y. Y. Podladchikov, and K. M. Zingerman, “An exact solution to the Lame problem for a hollow sphere for new types of nonlinear elastic materials in the case of large deformations,” Eur. J. Mech. A/Solids 90, 104345 (2021). https://doi.org/10.1016/j.euromechsol.2021.104345

V. A. Levin, L. M. Zubov, and K. M. Zingerman, “An exact solution to the problem of biaxial loading of a micropolar elastic plate made by joining two prestrained arc-shaped layers under large strains,” Eur. J. Mech. A/Solids. 88, 104237 (2021). https://doi.org/10.1016/j.euromechsol.2021.104237

V. A. Levin, Nonlinear Computational Mechanics of Strength, Vol. 1: Models and Methods. Formation and Development of Defects (Fizmatlit, Moscow, 2015) [in Russian].

V. A. Levin, Repeated Superposition of Large Deformations in Elastic and Viscoelastic Solids (Nauka, Moscow, 1999) [in Russian].

V. A. Levin, “Stress concentration near a hole, which is circular at the time of formation, in a body made of a viscoelastic materials,” Dokl. Akad. Nauk SSSR 299 (5), 1079–1082 (1988).

S. Tripathy, C. Chin, T. London, et al., “Process modeling and validation of powder bed metal additive manufacturing,” in Proc. of NAFEMS World Congress NWC-2017, Stockholm, 2017 (NAFEMS, 2017). https://www.researchgate.net/publication/319173249

S. M. Abramov, S. A. Amel’kin, L. V. Kljuev, et al., “Modeling the development of large plastic deformations in a rotating disk in the fidesys program,” Chebyshev. Sborn. 18 (3), 15–27 (2017). https://doi.org/10.22405/2226-8383-2017-18-3-15-27

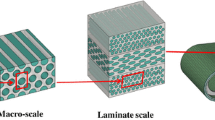

M. Y. Yakovlev, P. Tanasevich, A. V. Vershinin, and V. A. Levin, “Numerical analysis of effective thermophysical properties and stability of metamaterials with a negative coefficient of thermal expansion using CAE Fidesys,” in Abstracts of the International Conference “Physical Mesomechanics. Materials with a Multi-Level Hierarchically Organized Structure and Intelligent Production Technologies,” (TGU, Tomsk, 2021), pp. 340–341. https://doi.org/10.17223/978-5-907442-03-0-2021-212

M. Y. Yakovlev, P. Tanasevich, A. V. Vershinin, et al., “Application of the finite element method to modeling the effective mechanical and thermomechanical properties of metamaterials of the 3D lattice structure,” in Proc. of NAFEMS World Congress, 2021 (NAFEMS, 2021), pp. 403.

E. Barchiesi, F. dell’Isola, and F. Hild, “On the validation of homogenized modeling for bi-pantographic metamaterials via digital image correlation,” Int. J. Solids Struct. 208–209, 49–62 (2021). https://doi.org/10.1016/j.ijsolstr.2020.09.036

F. dell’Isola, A. Della Corte, I. Giorgio, and D. Scerrato, “Pantographic 2D sheets: Discussion of some numerical investigations and potential applications,” Int. J. Non-Lin. Mech. 80, 200–208 (2016). https://doi.org/10.1016/j.ijnonlinmec.2015.10.010

S. N. Shubin, A. B. Freidin, and A. G. Akulichev, “Elastomer composites based on filler with negative thermal expansion coefficient in sealing application,” Arch. Appl. Mech. 86, 351–360 (2016). https://doi.org/10.1007/s00419-016-1120-1

X.-L. Peng and S. Bargmann, “Tunable auxeticity and isotropic negative thermal expansion in three-dimensional lattice structures of cubic symmetry,” Extreme Mech. Lett. 43, 101201 (2021). https://doi.org/10.1016/j.eml.2021.101201

Q. Wang, J. A. Jackson, Q. Ge, et al., “Lightweight mechanical metamaterials with tunable negative thermal expansion,” Phys. Rev. Lett. 116, 175901 92016). https://doi.org/10.1103/PhysRevLett.117.175901

T. Bückmann, N. Stenger, M. Kadic, et al., “Tailored 3D mechanical metamaterials made by dip-in direct-laser-writing optical lithography,” Adv. Mater. 24 (20), 2710–2714 (2012). https://doi.org/10.1002/adma.201200584

S. E. Lapin and V. B. Pisetskiy, “Information to develop geoinformation safety panel of underground mining works based on related solutions in prognosis of the development of stressed state of the massif of mountain rocks and gas flows,” Chebyshev. Sborn. 18 (3), 350–362. (2017). https://doi.org/10.22405/2226-8383-2017-18-3-350-362

A. Myasnikov, A. Vershinin, and A. Sboychakov, “A generalization of geomechanical model for naturally fractured reservoirs,” in SPE Russian Petroleum Technology Conference and Exhibition, Moscow, Russia, October 2016 (SPE, 2016), SPE-182033-MS. https://doi.org/10.2118/182033-MS

A. Gupta, G. Penuela, and R. Avila, “An integrated approach to the determination of permeability tensors for naturally fractured reservoirs,” J. Can. Pet. Technol. 40 (12), PETSOC-01-12-02 (2001). https://doi.org/10.2118/01-12-02

A. Costa, “Permeability-porosity relationship: A reexamination of the Kozeny-Carman equation based on a fractal pore-space geometry assumption,” Geophys. Res. Lett. 33 (2), L02318 (2006). https://doi.org/10.1029/2005GL025134

M. Bagheri and A. Settari, “Modeling of geomechanics in naturally fractured reservoirs,” in SPE Reservoir Simulation Symposium. Houston, 2005 (SPE, 2005), pp. SPE–93083–MS. https://doi.org/10.2118/93083-MS

M. Bagheri and A. Settari, “Effects of fractures on reservoir deformation and flow modeling,” Can. Geotech. J. 43 (6), 574–586 (2006). https://doi.org/10.1139/T06-024

V. B. Pisetskiy, V. V. Vlasov, V. P. Cherepanov, et al., “Prediction of rock massif stability on the basis of the seismic location method during construction of underground structures,” Inzh. Izysk., No. 9–10, 46–51 (2014).

Yu. V. Shuvalov, G. I. Korshunov, A. V. Montikov, et al., “Geomechanical and gas-dynamic processes in a coal-bearing massif at high speeds of moving faces,” Gorniy Inf.-Analit. Bull. No. 6, 80–88 (2011).

A. B. Zhuravlev, V. I. Karev, Yu. F. Kovalenko, and K. B. Ustinov, “The effect of seepage on the stress–strain state of rock near a borehole,” J. Appl. Math. Mech. 78 (1), 56–64 (2014). https://doi.org/10.1016/j.jappmathmech.2014.05.007

M. Souley and A. Thoraval, “Nonlinear mechanical and poromechanical analyses: comparison with analytical solutions,” in Proc. COMSOL Conference, 2011, Stuttgart, Germany (COMSOL, 2011), pp. NC.ffineris00973639.

M. M. Carroll and O. Horgan, “Finite strain solutions for compressible elastic solid,” Quart. Appl. Math. 48 (3), 767–780 (1990). https://doi.org/10.1090/qam/1079919

J. M. Ball, “Discontinuous equilibrium solutions and cavitation in nonlinear elasticity,” Philos. Trans. Royal Soc. Ser A 306 (1496), 557–611 (1982). https://doi.org/10.1098/rsta.1982.0095

L. M. Zubov, “Universal solutions of nonlinear dislocation theory for elastic cylinder,” Mech. Solids 55, 701–709 (2020). https://doi.org/10.3103/S0025654420050167

L. M. Zubov, “Universal solution of nonlinear elasticity for a hollow cylinder with prestressed coatings,” Acta Mech. 230, 4137–4143 (2019). https://doi.org/10.1007/s00707-018-2333-x

V. A. Eremeev and L. M. Zubov, Mechanics of Elastic Shells (Nauka, Moscow, 2008) [in Russian].

R. Batra, F. dell’Isola, and G. Ruta, “Second-order solution of Saint-Venant’s problem for an elastic bar predeformed in flexure,” Int. J. Non-Lin. Mech. 40 (2-03), 411–422 (2005). https://doi.org/10.1016/j.ijnonlinmec.2004.08.002

M. Sharma and H. Wang, “A Fully 3-D, multi-phase, poro-elasto-plastic model for sand production,” in SPE Annual Technical Conference and Exhibition, Dubai, UAE, September 2016 (SPE, 2016), SPE–181566–MS. https://doi.org/10.2118/181566-MS

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M.K.Katuev

About this article

Cite this article

Levin, V.A. Digital Production Tool—a Package for Robust Engineering Analysis as a Tool for Transferring Fundamental Scientific Results to Industry on the Example of the Fidesys Package and the Theory of Multiple Superimposition of Large Deformations. Mech. Solids 58, 455–474 (2023). https://doi.org/10.3103/S002565442260115X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S002565442260115X