Abstract—

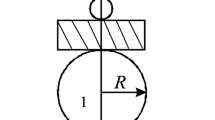

The article presents a review of the current state of experimental studies of the processes of deformation, destruction and filtration in rocks, the effect of the stress state on their deformation, strength, rheological and filtration characteristics. An analysis of the main results obtained in this area in recent years is carried out. A brief description of the most common methods of experimental research is presented. Key differences and features of the main methods are highlighted. A unique scientific setup, created at the Institute for Problems in Mechanics of the Russian Academy of Sciences, is described in more detail - the Triaxial Independent Loading Testing System (TILTS). The main scientific results, both fundamental and applied, obtained with its help are presented. The ways of modernization and improvement of the installation, which will significantly expand the range of tasks solved with its help, are described. Special attention in the article is paid to the analysis of works on mathematical modeling of the mechanical behavior of rocks, theoretical problems requiring experimental research are discussed.

Similar content being viewed by others

REFERENCES

K. S. Selivanov, “Evaluation of the surface material strength using the “Scratch-Test” method,” Vestn. UGATU 19 (1), 100–106 (2015).

T. Karman, “Festigkeitsversuche unter allseitigem Druck,” Z. Ver. Deutsch. Ing. 55, 1749–1757 (1911).

R. Böker, “Die Mechanik der bleibenden Formanderungen in Kristallinisch aufgebauten Körpern,” Ver. Deutsch. Ing. Mitt. Forsch. 175, 1–51 (1915).

M. P. Volarovich, I. S. Tomashevskaya, and V. A. Budnikov, Rock Mechanics at High Pressure (Nauka, Moscow, 1979) [in Russian].

M. P. Volarovich and E. I. Bayuk, “Influence of all-round pressures up to 4000 kg/cm2 upon the elastic properties of rock specimens,” Dokl. Akad. Nauk SSSR 135 (1), 65–68 (1960).

T. Horibe and R. Kobayashi, “Physical properties of coal-measures rocks under triaxial pressure,” J. Min. Soc. Japan. 74, 142–146 (1958).

M. S. Paterson, “A high-pressure, high-temperature apparatus for rock deformation,” Intern. J. Rock Mech. Mining Sci. 7, 517–526 (1970).

H. Zhang and C. C. Li, “Effects of confining stress on the post-peak behaviour and fracture angle of Fauske marble and Iddefjord granite,” Rock Mech. Rock Eng. 52, 1377–1385 (2019). https://doi.org/10.1007/s00603-018-1695-7

Y. Zong, L. Han, Y. Jin, W. Zhao, et al., “Experimental investigation on the post-peak short-term and creep behavior of fractured sandstone,” Energies 13, 598 (2020). https://doi.org/10.3390/en13030598

Y. Zong, L. Han, Q. Meng, and Y. Wang, “Strength properties and evolution laws of cracked sandstone samples in re-loading tests,” Int. J. Mining Sci. Tech. 30 (2), 251–258 (2020). https://doi.org/10.1016/j.ijmst.2019.03.004

Z. Wang, M. Shen, L. Gu, F. Zhang, “Creep behavior and long-term strength characteristics of greenschist under different confining pressures,” Geotech. Test. J. 41 (1), 55–71 (2018). doi:https://doi.org/10.1520/GTJ20170143

T. S. Nguyen, Z. Li, G. Su, M. H. B. Nasseri, et al., “Hydro-mechanical behavior of an argillaceous limestone considered as a potential host formation for radioactive waste disposal,” J. Rock Mech. Geotech. Eng. 10 (6), 1063–1081 (2018). https://doi.org/10.1016/j.jrmge.2018.03.010

S. Yang and B. Hu, “Creep and permeability evolution behavior of red sandstone containing a single fissure under a confining pressure of 30 MPa,” Sci. Rep. 10, 1900 (2020). https://doi.org/10.1038/s41598-020-58595-2

S. Yang, Y-H. Huang, and P. G. Ranjith, “Failure mechanical and acoustic behavior of brine saturated-sandstone containing two pre-existing flaws under different confining pressures,” Eng. Fract. Mech. 193, 108-121 (2018). https://doi.org/10.1016/j.engfracmech.2018.02.021

O. Hamza and R. Stace, “Creep properties of intact and fractured muddy siltstone,” Int. J. Rock Mech. Mining Sci. 106, 109–116 (2018).

D. A. Martyushev, S.V. Galkin, and V. V. Shelepov, “The influence of the stress state of rocks on the matrix and fracturing Permeability in the conditions of various lithologic-facial zones of the Turn-Famen oil deposits of the Upper Kama region,” Vest. Mosk. Univ. Ser. 4 Geologia, No. 5, 44–52 (2019). https://doi.org/10.33623/0579-9406-2019-5-44-52

A. L. Khashper, T. R. Aminev, A. I. Fedorov, and A. V. Zhonin, “Research of dependence of rock permeability on its stress-strain state,” Geol. Vest., No. 1, 133–140 (2019). https://doi.org/10.31084/2619-0087/2019-1-10

A. L. Khashper, T. R. Aminev, A. I. Fedorov, and A. V. Zhonin, “Study of the influence of the stress-strain state of a rock on its permeability,” in Proceedings of the VII All-Russian Youth Geological Conference “Geology, Geoecology and Resource Potential of the Urals and Adjacent Territories,” Ufa, 23–27 September, 2019 (RN-BashNIPIneft’, Ufa, 2019), pp. 193–196.

A. L. Khashper, T. R. Aminev, A. I. Fedorov, and A. V. Zhonin, “Study of the dependence of rock permeability on its stress-strain state,” in Proceedings of the VI All-Russian Youth Geological Conference “Geology, Geoecology and Resource Potential of the Urals and Adjacent Territories,” Ufa, 25–29 September, 2018 (Svoyo Izdat., St. Petersburg, 2018), pp. 185–188.

M. M. Pritidyakonov, E. I. Il’nitskaya, and V. I. Karpov, “Methods for studying the mechanical properties of rocks under conditions of volumetric stress state,” in Mechanical Properties of Rocks (AN SSSR, Moscow, 1963), pp. 151–156.

K. Mogi, “Fracture and flow of rocks under high triaxial compression,” J. Geophys. Res. 76, 1255–1269 (1971). https://doi.org/10.1029/JB076i005p01255

P. V. Lade, “Rock strength criteria: the theories and the evidence,” Compr. Rock Eng., No. 1. P. 255-284 (1993).

J. Labuz, S-T. Dai, and E. Papamichos, “Plane-strain compression of rock-like materials,” Int. J. Rock Mech. Min. Sci. Geomech. Abstr., No. 33, 573–584 (1996).

L. Shi, X. Li, B. Bai, A. Wang, et al., “A Mogi-type true triaxial testing apparatus for rocks with two moveable frames in horizontal layout for providing orthogonal loads,” Geotech. Test. J., No. 40, 542–558 (2017). https://doi.org/10.1520/GTJ20160242

M. Sato, T. Takemura, and M. Takahashi, “Development of the permeability anisotropy of submarine sedimentary rocks under true triaxial stresses,” Int. J. Rock Mech. Mining Sci. 108, 118–127 (2018). doi:.https://doi.org/10.1016/j.ijrmms.2018.06.010

GCTS Testing Systems. https://www.gcts.com/?s=prod_ver&p=products&ID=199#tab-1.

GDS Instruments. https://www.gdsinstruments.com/gds-products/gds-true-triaxial-apparatus.

True Triaxial Testing of Rocks, Ed. by M. Kwasniewski, X. Li, M. Takahashi (CRC Press, London, 2012).

T. Georgieva, F. Descamps, N. Gonze, et al., “Stability assessment of a shallow abandoned chalk mine of Malogne (Belgium),” Eur. J. Environ. Civ. En., 2020, 1–15 (2020). https://doi.org/10.1080/19648189.2020.1762752

R. P. Young, M. H. B. Nasseri, and L. Lombos, “Imaging the effect of the intermediate principal stress on strength, deformation and transport properties of rocks using seismic methods,” in True Triaxial Testing of Rocks, Ed. by M. Kwasniewski, X. Li, M. Takahashi (CRC Press, London, 2012), Chapt. 11.

V. Minaeian, D. N. Dewhurst, and V. Rasouli, “An investigation on failure behaviour of a porous sandstone using single-stage and multi-stage true triaxial stress tests,” Rock Mech. Rock Eng. 53, 3543–3562 (2020). https://doi.org/10.1007/s00603-020-02134-y

V. Rasouli, “A true triaxial stress cell (TTSC) used for simulations of real field operations in the lab,” in True Triaxial Testing of Rocks, Ed. by M. Kwasniewski, X. Li, M. Takahashi (CRC Press, London, 2012), Chapt. 24.

A. Rezagholilou and M. Sarmadivaleh, “Design and application of a high-performance true triaxial stress cell,” Insights Min. Sci. Technol. 1(5), 555573 (2019). https://doi.org/10.19080/IMST.2019.01.555573

A. Nabipour, “Experimental and numerical study of ultrasonic monitoring of hydraulic fracture propagation,” PhD Thesis (Curtin University, Australia, 2013).

V. Minaeian, “True triaxial testing of sandstones and shales,” PhD Thesis (Curtin University. Australia, 2014).

Z. Li, L. Wang, Y. Lu, et al., “Experimental investigation on true triaxial deformation and progressive damage behaviour of sandstone,” Sci. Rep. 9 (3386) (2019). https://doi.org/10.1038/s41598-019-39816-9

B. Baizhanov, D. Katsuki, A.N. Tutuncu, et al., “Experimental investigation of coupled geomechanical, acoustic, and permeability characterization of berea sandstone using a novel true triaxial assembly,” Rock. Mech. Rock. Eng. 52, 2491–2503 (2019). https://doi.org/10.1007/s00603-019-01816-6

X.-T. Feng, X. Zhang, R. Kong, and G. Wang, “A novel mogi type true triaxial testing apparatus and its use to obtain complete stress–strain curves of hard rocks,” Rock. Mech. Rock. Eng. 49 (5), 1649–1662 (2015). https://doi.org/10.1007/s00603-015-0875-y

D. Asahina, M. Sato, and M. Takahashi, “Laboratory observations of fracture plane reactivation induced by pore pressure in Kimachi sandstone,” in Proceed. Rock Dyn. Summit. 2019, pp. 101–105. https://doi.org/10.1201/9780429327933-14

D. Asahina, P. Pan, M. Sato, et al., “Hydraulic and mechanical responses of porous sandstone during pore pressure-induced reactivation of fracture planes: an experimental study,” Rock. Mech. Rock. Eng. 52, 1645–1656 (2019). https://doi.org/10.1007/s00603-018-1706-8

X. Feng, J. Zhao, X. Zhang, et al., “A novel true triaxial apparatus for studying the time-dependent behaviour of hard rocks under high stress,” Rock. Mech. Rock. Eng. 51, 2653–2667 (2018)https://doi.org/10.1007/s00603-018-1516-z

J. Zhao, X.-T. Feng, X. Zhang, et al., “Time-dependent behaviour and modeling of Jinping marble under true triaxial compression,” Int. J. Rock Mech. Mining. Sci. 110, 218–230 (2018).

J. Zhao, X.-T. Feng, X. Zhang, et al., “Brittle-ductile transition and failure mechanism of Jinping marble under true triaxial compression,” Eng. Geol. 232, 160–170 (2018).

J. Zhao, X.-T. Feng, X. Zhang, and C. Yang, “Brittle and ductile creep behavior of Jinping marble under true triaxial stress,” Eng. Geol. 258, 105157 (2019). https://doi.org/10.1016/j.enggeo.2019.105157

Feng X.-T., Kong R., Zhang X., Yang C. Experimental Study of Failure Differences in Hard Rock Under True Triaxial Compression // Rock. Mech. Rock. Eng. 52, 2109–2122 (2019). https://doi.org/10.1007/s00603-018-1700-1

X.-T. Feng, et al., “Evolution of the mechanical and strength parameters of hard rocks in the true triaxial cyclic loading and unloading tests,” Int. J. Rock Mech. Mining Sci. 131, 104349 (2020).

M. Duan, C. Jiang, Q. Gan et al., “Study on permeability anisotropy of bedded coal under true triaxial stress and its application,” Transp. Porous Med. 131, 1007–1035 (2020). https://doi.org/10.1007/s11242-019-01375-y

Y. Liu, et al., “Permeability evolution of anthracite coal considering true triaxial stress conditions and structural anisotropy,” J. Nat. Gas Sci. Eng. 52, 492–506 (2018).

A. V. Garcia, R. M. Rached, and J. C. Santamarina, “Large-scale true triaxial apparatus for geophysical studies in fractured rock,” Geotech. Test. J. 41 (4), 821–829 (2018).

C. Couture and P. Bésuelle, “Diffuse and localized deformation of a porous Vosges sandstone in true triaxial conditions,” Int. E3S Web. Conf. 2019 92, 06007 (2019). https://doi.org/10.1051/e3sconf/20199206007

J. Lu, G. Yin, X. Li, et al., “Deformation and CO2 gas permeability response of sandstone to mean and deviatoric stress variations under true triaxial stress conditions,” Tunnelling Underground Space Tech. 84, 259-272 (2019).

D. M. Klimov, V. I. Karev, and Y. F. Kovalenko, “Experimental study of the influence of a triaxial stress state with unequal components on rock permeability,” Mech. Solids 50 (6), 633–640 (2015). https://doi.org/10.3103/S0025654415060047

V. I. Karev, D. M. Kilmov, Y. F. Kovalenko, and K. B. Ustinov, “Experimental study of rock creep under true triaxial loading,” Mech. Solids 54 (8), 1151–1156 (2019). https://doi.org/10.3103/S0025654419080041

V. I. Karev, Y.F. Kovalenko, and K.B. Ustinov, Geomechanics of Oil and Gas Wells. Advances in Oil and Gas Exploration and Production (Springer, Cham, 2020).

V. I. Karev, Yu. F. Kovalenko, and V.V. Khimulia, “Influence of stresses on strength and filtration properties of rocks in the vicinity of horizontal well,” Prots. Geosred., No. 1 (14), 746–756 (2018).

V. I. Karev, D. M. Klimov, Y. F. Kovalenko, and K. B. Ustinov, “Modelling of mechanical and filtration processes near the well with regard to anisotropy,” J. Phys.: Conf. Series. 991 (1), 012039 (2018). https://doi.org/10.1088/1742-6596/991/1/012039

H. Tang, D. Wang, R. Huang, et al., “A new rock creep model based on variable-order fractional derivatives and continuum damage mechanics,” Bull. Eng. Geol. Environ. 77, 375–383 (2018). https://doi.org/10.1007/s10064-016-0992-1

A. Singh, A. Kumar, and K. S. Rao, “Strength behaviour of anisotropic rock under true triaxial stress state,” in ISRM International Symposium - 10th Asian Rock Mechanics Symposium, October 29–November 3, 2018, Singapore (Singapore, 2018), N. ISRM-ARMS10-2018-227.

X. Li, C. Qi, and Z. Shao, “A microcrack growth-based constitutive model for evaluating transient shear properties during brittle creep of rocks,” En. Fract. Mech. 194, 9–23 (2018). https://doi.org/10.1016/j.engfracmech.2018.02.034

Y. Zhao, Z. Lianyang, W. Wang, et al., “Separation of elastoviscoplastic strains of rock and a nonlinear creep model,” Int. J. Geomech. 18 (1), 04017129 (2018). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001033

Y. Zhao, Y. Wang, W. Wang, et al., “Modeling of rheological fracture behavior of rock cracks subjected to hydraulic pressure and far field stresses,” Theor. Appl. Fract. Mech. 101, 59–66 (2019). https://doi.org/10.1016/j.tafmec.2019.01.026

O. Sudakov, E. Burnaev, and D. Koroteev, “Driving digital rock towards machine learning: Predicting permeability with gradient boosting and deep neural networks,” Comp. Geosci. 127, 91–98 (2019). https://doi.org/10.1016/j.cageo.2019.02.002

X. Wang, Y. Yin, J. Wang, et al., “A nonstationary parameter model for the sandstone creep tests,” Landslides 15 (7), 1377–1389 (2018). https://doi.org/10.1007/s10346-018-0961-9

M. A. Semin, A.V. Zaitsev, and L. Yu. Levin, “Simulation of oil seepage in fractured porous reservoirs in case of Yarega high-viscosity oil field,” Izv. Tul’skogo Gos. Univ. Nauki Zemle, No. 3, 270–284 (2018).

Funding

The study was carried out with the financial support of the Russian Foundation for Basic Research within the framework of the scientific project no. 20-11-50047 Expansion.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. K. Katuev

About this article

Cite this article

Karev, V.I., Khimulia, V.V. & Shevtsov, N.I. Experimental Studies of the Deformation, Destruction and Filtration in Rocks: A Review. Mech. Solids 56, 613–630 (2021). https://doi.org/10.3103/S0025654421050125

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654421050125