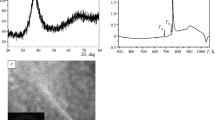

Abstract—To determine the cracking susceptibility for amorphous metal alloys (AMAs) or metallic glasses, a method based on the determining the dependence of the relative crack resistance (χ) on the load applied to intender of PMT-3 microhardness tester is proposed. In the method, the relative crack resistance at a load of 160 g is set equal to unit. At lower loads, crack resistance has been determined as the average of 10 measurements. In this article, we also have proposed a method for determining the heating temperature of AMA ribbons during laser beam machining that is based on a comparison of the dependence of the relative crack resistance of AMAs on load applied to indenter for samples annealed in the furnace and after laser irradiation. It has been found that cracks begin to appear in the samples after a ten-minute annealing at Т = 773 K.

Fatigue tests of samples under a load varying from a maximum value of 750 MPa to a minimum of 400 MPa under a condition of repeated stress cycle with a frequency of 2 Hz have been carried out using a specially designed setup. In the domain exposed to laser radiation, four characteristic areas can be distinguished on the sample surface: internal reflow zone; dendritic growth area; area with unfinished growth of dendrites, area not exposed to radiation. In these areas, the relative crack resistance (χ) determined via the critical stress intensity factor of the first kind K1c monotonically decreases from 1 in the center to 0 at the periphery. It has been established that the laser action does not affect fatigue, the fatigue limit of the samples remains the same and is equal to 428 MPa. The characteristic features of the destruction are revealed. Cracks that propagate with branching in the reflow zone and after passing through its boundary develop rectilinearly have been found.

Similar content being viewed by others

REFERENCES

I. V. Zolotukhin and Yu. E. Kalinin, “Amorphous metallic alloys,” Usp. Fiz. Nauk, 160, 75–110 (1990) [Sov. Phys. Usp. (Engl. Transl.) 33 (9) 720–738 (1990)].

D. D. Gilman and Kh. D. Limi, Metallic Glasses (Metallurgia, Moscow, 1984) [in Russian].

Amorphous Metal Alloys, Ed. by F. E. Lyuborsky (Metallurgiya, Moscow, 1987) [in Russian].

A. M. Glezer, I. E. Permyakova, V. E. Gromov, and V. V. Kovalenko, The Mechanical Behavior of Amorphous Alloys (SibGIU, Novokuznetsk, 2006) [in Russian].

V. P. Alekhin and V. A. Khonik, The Structure and Physical Deformation Patterns of Amorphous Alloys (Metallurgiya, Moscow, 1992) [in Russian].

A. L. Petrov, A. A. Gavrilyuk, and S. M. Zubritskii, Structure and Properties of Disordered Solids: Manual (Irkutskiy Gos. Uni., Irkutsk, 2004) [in Russian].

I. V. Zolotukhin, Physical Properties of Amorphous Metallic Materials (Metallurgiya, Moscow, 1986) [in Russian].

K. Suzuki, H. Fujimori, and K. Hashimoto, Amorphous Metals (Butterworths, London, 1983; Metallurgiya, Moscow, 1987).

V. A. Fedorov, T. N. Pluzhnikova, and S. A. Sidorova, “The effect of pulsed electric current on the dependence mechanical stress-deformation in amorphous and nanocrystalline metallic alloys,” Izv. Vyssh. Uch. Zav. Chern. Metall., No 12, 62–64 (2013).

V. A. Fedorov and A. V. Yakovlev, “Manifestation electroplastic effect in metallic galss,” Vektor Nauki Tolyatti. Gos. Uni, No. 3, 99–105 (2013).

V. V. Stolyarov, “Electroplastic effect in nanocrystalline and amorphous alloys,” Mater. Sci. Technol. 31 (13), 1536–1540 (2015).

P. Yiu, C. H. Hsueh, and C. H. Shek, “Electroplastic forming in a Fe-based metallic glass ribbon,” J. Alloys Compd.658, 795–799 (2016).

A. V. Korolev, N. I. Kourov, V. G. Pushin, et al., “Paramagnetic susceptibility of the Zr62Cu22Al10Fe5Dy1 metallic glass subjected to high-pressure torsion deformation,” J. Magn. Magn. Mater.437, 67–71 (2017).

B. Huang, et al., “Saturated magnetization and glass forming aability of soft magnetic Fe-based metallic glasses,” Intermetallics 84, 74–81 (2017).

A. V. Yakovlev, T. N. Pluzhnikova, D. Yu. Fedotov, et al., “The magnetic properties of amorphous metal alloys due to external effects,” Vestn. Tambov. Uni. Ser. Estestv. Tekh. Nauki, 21 (3), 1453–1455 (2016).

E. V. Boltynjuk, D. V. Gunderov, E. V. Ubyivovk, et al., “Enhanced strain rate sensitivity of Zr-based bulk metallic glasses subjected to high pressure torsion,” J. Alloys Compd. 747, 595–602 (2018).

A. Inoue, “Bulk glassy alloys: historical development and current research,” Engng 1 (2), 185–191 (2015).

H. F. Li and Y. F. Zheng, “Recent advances in bulk metallic glasses for biomedical applications,” Acta Biomater. 36, 1– (2016).

Wu Chenguang, et al., “Thermoplastic deformation of ferromagnetic Co Fe based bulk metallic glasses,” Appl. Phys. A. 123:742 (2017).

S.-H. Joo, D.-H. Pi, A. D. H. Setyawan, et al., “Work-hardening induced tensile ductility of bulk metallic glasses via highpressure torsion,” Sci. Reports. 5: 9660 (2015).

B. Bikramjit, Biomaterials Science and Tissue Engineering: Principles and Methods (Cambridge University Press, Cambridge, 2017).

ACKNOWLEDGMENTS

This study was supported by the Russian Foundation for Basic Research (grant no. 18-01-00513).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A.A. Borimova

About this article

Cite this article

Berezner, A.D., Pluzhnikova, T.N., Fedorov, V.A. et al. Behaviour of Metallic Glasses under Local Loading and after External Action. Mech. Solids 55, 16–21 (2020). https://doi.org/10.3103/S0025654420010057

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654420010057