Abstract

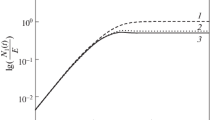

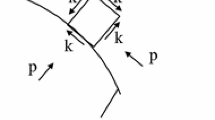

The paper deals with rigid-plastic materials satisfying the vonMises plasticity condition under the assumption that their yield point in pure shear depends only on the equivalent strain rate (rigid-viscoplastic material models). The rigid-viscoplastic models are classified by the yield point behavior in pure shear as the equivalent strain rate tends to zero or infinity. All in all, four classes of rigid-viscoplastic material models are distinguished. For each of these classes of material models, the solution is constructed for the translational motion of an axisymmetric rigid bar along its symmetry axis in a rigid-plastic medium. It is assumed that the maximum friction law acts on the surface of contact between the bar and the rigid-viscoplastic medium. It is shown that the solutions provided by models of different classes qualitatively differ from each other. A qualitative comparison with experimental results known in the literature is carried out. It is shown that predicting the formation of an intensive plastic deformation layer near the friction surface, which is observed in experiments, is possible if the rigid-viscoplastic model contains the saturation stress (the stress, bounded in magnitude, to which the yield point in pure shear tends as the equivalent strain rate tends to infinity).

Similar content being viewed by others

References

A. A. Il’yushin, “To the Problem of Viscoplastic Flow of a Material,” in Collective Works, Vol. 1 (1935–1945) (Fizmatlit, Moscow, 2004), pp. 115–131 [in Russian].

P. P. Mosolov and V. P. Myasnikov, Mechanics of RigidplasticMedia (Nauka, Moscow, 1981) [in Russian].

N. N. Malinin, Creep inMetal Working (Mashinostroenie, Moscow, 1986) [in Russian].

V. Sanabria, S. Mueller, S. Gall, and W. Reimers, “Investigation of Friction Boundary Conditions during Extrusion of Aluminium and Magnesium Alloys,” Key Engng Mater. 611–612, 997–1004 (2014).

B. J. Griffiths, “Mechanism of White Layer Generation with Reference to Machining and Deformation Processes,” Trans ASME. J. Trib. 109, 525–530 (1987).

T. Murai, S. Matsuoka, S. Miyamoto, and Y. Oki, “Effects of Extrusion Conditions on Microstructure and Mechanical Properties of AZ31B Magnesium Alloy Extrusion,” J. Mater. Process. Technol. 141, 207–212 (2003).

A. A. Milenin, S. Berski, G. Banaszek, and H. Dyja, “Theoretical Analysis and Optimization of Parameters in Extrusion Process of Explosive Cladded Bimetallic Rods,” J. Mater. Process. Technol. 157–158, 208–212 (2004).

S. Kajino and M. Asakawa, “Effect of “Additional Shear Strain Layer” on Tensile Strength and Miscostructure of Fine DrawnWire,” J. Mater. Process. Technol. 177, 704–708 (2006).

T. A. Trunina and E. A. Kokovikhin, “Formation of Highly Dispersed Structure in Surface Layers of Steel under Combined Treatment with Hydraulic Forging,” Probl. Mashinostr. Nadezhn. Mashin., No. 2, 71–74 (2008).

S. E. Aleksandrov, D. Z. Grabko, and O. A. Shikimakha, “To the Determination of Intensive Strain Layer Thickness near the Friction Surface in Metal Forming Processes,” Probl. Mashinostr. Nadezhn. Mashin., No. 3, 72–78 (2009).

T. T. Sasaki, R. A. Morris, G. B. Thompson, et al., “Formation of Ultra-Fine Copper Grains in Copper-Clad Aluminum Wire,” ScriptaMater. 63, 488–491 (2010).

M. Thirumurugan, S. A. Rao, S. Kumaran, and T. S. Rao, “Improved Ductility in ZM21 Magnesium–Aluminium Macrocomposite Produced by Co-Extrusion,” J. Mater. Process. Technol. 211, 1637–1642 (2011).

X. Li, G. Zu, M. Ding, et al., “Interfacial Microstructure and Mechanical Properties of Cu/Al Clad Sheet Fabricated by Asymmetrical Roll Bonding and Annealing,” Mater. Sci. Technol. 529A, 485–491 (2011).

R. V. Goldstein and S. E. Aleksandrov, “An Approach to the Prediction ofMaterialMicrostructure Formation near the Friction Surface under Developed Strains,” Fiz. Mezomekh. 17 (5), 15–20 (2014).

S. E. Aleksandrov and R. V. Goldstein, “On Constructing Constitutive Equations in Material Thin Layer near Friction Surfaces in Material Forming Processes,” Dokl. Ross. Akad. Nauk 460 (3), 283–285 (2015) [Dokl. Phys. (Engl. Transl.) 60 (1), 9–41 (2015)].

S. Alexandrov and O. Richmond, “Singular Plastic Flow Fields near Surfaces ofMaximum Friction Stress,” Int. J. Non-Lin. Mech. 36 (1), 1–11 (2001).

N. Gurung, “1-D Analytic Solution for Extensible and Inextensible Soil/Rock Reinforcement in Pull-out Tests,” Geotext. Geomembr. 19, 195–212 (2001).

B. Banhoilzer, W. Brumeshuber, and W. Jung, “Analytical Simulation of Pull-Out Tests — the Direct Problem,” Cement & Concr. Compos. 27, 93–101 (2005).

B. Banhoilzer, W. Brumeshuber, and W. Jung, “Analytical Evaluation of Pull-Out Tests — the Inverse Problem,” Cement & Concr. Compos. 28, 564–571 (2006).

L. Bouazaoui and A. Li, “Analysis of Steel/Concrete Interfacial Shear Stress by Means of Pull-Out Test,” Int. J. Adhesion & Adhesives 28, 101–108 (2008).

L. B. Martin, M. Tijani, and F. Hadj-Hassen, “ANew Analytical Solution to theMechanical Behavior of Fully Grouted Rockbolts Subjected to Pull-Out Tests,” Construct. Build. Mater. 25, 749–755 (2011).

S. E. Aleksandrov and R. V. Goldstein, “Pull-Out of a Rigid Fibre from an ElastoplasticMatrix,” Prikl. Mat. Mekh. 64 (1), 160–166 (2000) [J. Appl. Math. Mech. (Engl. Transl.) 64 (1), 155–161 (2000)].

J. G. Oldroyd, “Non-Newtonian Flow of Liquids and Solids,” in Rheology: Theory and Applications, Ed. by F. R. Eirich, Vol. 1 (Academic Press, New York, 1956), pp. 653–682.

J. M. Dealy and K. F. Wissbrun, Melt Rheology and Its Role in Plastic Processing (Van Nostrand Reinhold, New York, 1990).

E. Mitsoulis and S. G. Hatzikiriakos, “Capillary Extrusion Flow of a Fluropolymer Melt,” Int. J. Mater. Form. 6, 29–40 (2013).

S. A. Shesterikov and M. A. Yumasheva, “Specification of Equation of State in Creep Theory,” Izv. Akad. Nauk SSSR. Mekh. Tverd. Tela, No. 1, 86–91 (1984) [Mech. Solids. (Engl. Transl.)].

S. E. Aleksandrov, V. L. Danilov, and N. N. Chikanova, “On the Stagnation Zone in a Simulation of Axisymmetric Pressure Metal Forming under Creep,” Izv. Akad. Nauk. Mekh. Tverd. Tela, No. 1, 149–151 (2000) [Mech. Solids (Engl. Transl.) 35 (1), 127–129 (2000)].

S. Alexandrov and N. Alexandrova, “On the Maximum Friction Law in Viscoplasticity,” Mech. Time- Depend. Mater. 4 (1), 99–104 (2000)

A. S. Monin and A. M. Yaglom, Statistical Hydromechanics (Nauka, Moscow, 1965) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.E. Aleksandrov, R.V. Goldstein, 2015, published in Izvestiya Akademii Nauk. Mekhanika Tverdogo Tela, 2015, No. 4, pp. 28–37.

About this article

Cite this article

Aleksandrov, S.E., Goldstein, R.V. Motion of a rigid bar in a rigid-viscoplastic medium: The influence of the model type on the solution behavior. Mech. Solids 50, 389–396 (2015). https://doi.org/10.3103/S0025654415040044

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654415040044