Abstract

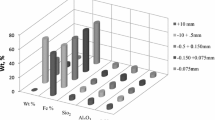

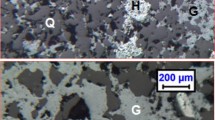

Low-grade iron ore received from the West Singhbhum area of Jharkhand state in India was used to develop a beneficiation flow sheet to remove alumina (Al2O3) and silica (SiO2) from the ore to get iron (Fe)-rich product for steel plants. Mineral characterization showed that the main mineral constituents present in the head sample are goethite, limonite, hematite, quartz, clay and gibbsite. The head sample contained about 49.2 percent Fe, 8.79 percent alumina and 12.01 percent silica. The received iron ore sample is amenable to upgradation through beneficiation to get pellet grade concentrate. The beneficiation process was established, involving crushing, screening, jigging, spiral separation, size reduction, desliming and magnetic separation. The process showed significant enrichment in Fe values to 63.5 percent Fe in concentrate, from 49.2 percent Fe. From the developed flow sheet, it is possible to obtain pellet grade fines with 63.5 percent Fe, 2.92 percent SiO2 and 2.61 percent Al2O3 with 50.6 percent weight recovery. The overall tailing loss is 49.4 percent with 34.3 percent Fe, 21.28 percent SiO2 and 14.64 percent Al2O3.

Similar content being viewed by others

References

Dey, S., Pani, S., Mohanta, M.K., and Singh, R., 2012, “Utilization of iron ore slimes: a future prospective”, Separation Science and Technology, Vol. 47, No. 5, pp. 769–776, https://doi.org/10.1080/01496395.2011.621501.

Li., C., Sun, H., Bai, J., and Li, L., 2009, “Innovative methodology for comprehensive utilization of iron ore tailing Part 1, The recovery of iron ore tailings using magnetic separation after magnetizing roasting”, Journal of Hazardous Materials, Vol. 174, No. 1–3, pp. 71–77, https://doi.org/10.1016/j.jhazmat.2009.09.018.

Olubambi, P.A., and Potgietez, J.H., 2005, “Effectiveness of gravity concentration for the beneficiation of Itakpe (Nigeria) iron ore achieved through jigging operation”, Journal of Minerals and Material Characterization and Engineering, Vol. 4, No. 1, pp 21–24, https://doi.org/10.4236/jmmce.2005.41003.

Mishra, B.K., and Adhikari, B., 1999, “Analysis of fluid motion during jigging, Minerals Engineering”, Mineral Engineering, Vol. 12, No. 12, pp.1469–1477, https://doi.org/10.1016/s0892-6875(99)00135-1.

Mukherjee, A.K., and Mishra, B.K., 2006a, “Role of water velocity for efficient jigging of iron ore”, Mineral Engineering, Vol. 19, No. 9, pp. 952–959, https://doi.org/10.1016/j.mineng.2005.10.023.

Mukherjee, A.K., and Mishra, B.K., 2006b, “An integral assessment of the role of critical process parameters on jigging”, International Journal of Mineral Processing, Vol. 81, No. 3, pp. 187–200, https://doi.org/10.1016/j.minpro.2006.08.005.

Shivamohan, R., and Forssberg, E., 1985, “Principles of spiral concentration”, International Journal of Mineral Processing, Vol. 15, pp. 503–519, 319B, https://doi.org/10.1016/0301-7516(85)90033-x.

Suthers, S.P., Venkata, N., Tripathi, A., Jeffrey, D., and Sarath, H., 2014, “Experimental study on beneficiation of low grade iron ore fines using hydrocyclone, desliming, reduction roasting and magnetic separation”, Mineral Processing and Extractive Metallurgy, Vol. 123, No. 4, pp. 212–227, https://doi.org/10.1179/1743285514y.0000000067.

Xiong, D.-H., 1997, “Development and commercial test of SLon-2000 vertical ring and pulsating high gradient magnetic separator”, Magnetic and Electrical Separation, Vol. 8, No. 2, pp. 89–100, https://doi.org/10.1155/1997/49803.

Xiong, D.-H., 2002, “A large scale application of SLon magnetic separator in Meishan Iron Ore Mine”, Magnetic and Electrical Separation, Vol. 11, pp. 1–8.

Xiong D.-H., Liu, S., and Chen, J., 1998, “New technology of pulsating high gradient magnetic separation”, International Journal of Mineral Processing, Vol. 54, pp. 111–127, https://doi.org/10.1016/s0301-7516(98)00009-x.

Vinod, K., Venkatesh, A.S., Sharma, T., and Jadhav, G.N., 2002, “Ore mineralogical characterization of low-grade ironores from Noamundi iron ore mines, Eastern India: An implication for beneficiation. Extended Abstract”, Proceedings of the International Seminar on Mineral Processing Technology (MPT-2002), Jan. 3–5, 2002, Bangalore.

Yu, Y., and Qi, C., 2011, “Magnetizing roasting mechanism and effective ore dressing process for oolitic hematite ore”, Journal of Wuhan University of Technology-Mater. Sci. Ed, Vol. 26, No. 2, pp. 176–181, https://doi.org/10.1007/s11595-011-0192-6.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Umadevi, T., Abhishek, K., Sah, R. et al. Development of process for beneficiation of low-grade iron ore consisting of goethite. Mining, Metallurgy & Exploration 35, 35–45 (2018). https://doi.org/10.19150/mmp.8056

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.19150/mmp.8056