Abstract

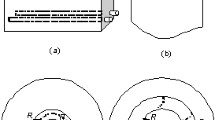

In reinforced concrete structures, corrosion of the rebar produces 2–6 times more corrosion product than the original material, creating pressure on the surrounding concrete, leading to cracking. The study of corrosion and cracking in reinforced concrete structures is therefore of great importance for enhancing the durability of concrete. Unlike many previous studies, we used ribbed rebar similar to that used commercially and considered the mechanical behavior of the interface transition zone (ITZ) between the aggregate and mortar to simulate the processes of corrosion and cracking of reinforced concrete structures. We explored the failure mode of the interface layer under uniform corrosion and the influence of different factors on the corrosion expansion cracking and the shedding mode of a concrete cover. This was achieved by establishing a three-phase meso-scale model of concrete based on secondary development of ABAQUS, simulating the mechanical behavior of the ITZ using a cohesive element, and establishing a rust expansion cracking model for single and multiple rebars. The results showed that: (1) Under uniform rust expansion, concrete cracks are distributed in a cross pattern with a slightly shorter lower limb. (2) When the corrosion rate is low, the ITZ is not damaged. With an increase in the corrosion rate, the proportion of elements with tensile damage in the ITZ first increases and then decreases. (3) In the case of a single rebar, the larger the cover thickness, the higher the corrosion rate corresponding to ITZ failure, and the arrangement of the rebar has little influence on the ITZ failure mode. (4) In the case of multiple rebars, the concrete cover cracks when the rebar spacing is small, and wedge-shaped spalling occurs when the spacing is large.

Abstract

目的

钢筋混凝土结构中, 钢筋锈蚀会产生2~6倍于自身的锈蚀产物, 对周围混凝土产生压力进而导致混凝土开裂。因此研究钢筋混凝土结构锈胀开裂对提升其耐久性具有重要意义。本文旨在研究钢筋混凝土锈胀开裂过程, 并探究均匀锈蚀下不同因素对锈胀裂缝形态和保护层脱落模式的影响。

创新点

1. 采用更接近实际的带肋钢筋;2. 考虑骨料与砂浆间界面过渡区(ITZ)的力学行为;3. 提出一种基于椭球体生成的单个不规则十二面体骨料及相应骨料库的生成、投放思路, 并在此基础上对ABAQUS进行二次开发, 构建一种基于已划分网格的直接生成三维实体的细观模型建立方法。

方法

1. 通过ABAQUS的二次开发建立骨料库的生成及投放方法;2. 通过ABAQUS的二次开发, 采用Cohesive单元模拟ITZ的力学行为;3. 通过上述方法构建单根及多根钢筋情况下的锈胀开裂模型;4. 通过不同钢筋横截面布置方式及保护层厚度的多组工况的仿真模拟, 分析单根钢筋及多根钢筋情况下布置方式及保护层厚度对锈胀裂缝形态的影响。

结论

1. 匀性锈胀下混凝土裂缝呈下方稍短的“十”字形分布。2. 锈蚀率较小时, ITZ不发生破坏;随着锈蚀率的增大, ITZ以拉伸破坏为主的单元占比出现先上升、后下降、再上升、最后趋于稳定的现象。3. 单根钢筋情况下, 保护层越大, ITZ开始产生破坏对应的锈蚀率越大;钢筋布置形式对ITZ破坏模式影响较小。4. 多根钢筋情况下, 钢筋间距较小时混凝土保护层发生层裂破坏, 间距较大时发生楔形剥落。

Similar content being viewed by others

References

Amalia Z, Qiao D, Nakamura H, et al., 2018. Development of simulation method of concrete cracking behavior and corrosion products movement due to rebar corrosion. Construction and Building Materials, 190:560–572. https://doi.org/10.1016/j.conbuildmat.2018.09.100

Cheng XD, Su QZ, Ma FL, et al., 2018. Investigation on crack propagation of concrete cover induced by nonuniform corrosion of multiple rebars. Engineering Fracture Mechanics, 201:366–384. https://doi.org/10.1016/j.engfracmech.2018.07.037

Fang Q, Zhang JH, Huan Y, et al., 2013. The investigation into three-dimensional mesoscale modelling of fully-graded concrete. Engineering Mechanics, 30(1):14–21 (in Chinese). https://doi.org/10.6052/j.issn.1000-4750.2011.06.0398

Hu ZJ, Xia LL, Cheng C, et al., 2020. Investigation on corrosion-induced cracking and corrosion expansive pressure in reinforced concrete members. Journal of Harbin Institute of Technology, 52(3):99–105 (in Chinese). https://doi.org/10.11918/201812061

ISO (International Organization for Standardization), 2015. Steel for the Reinforcement of Concrete-Part 2: Ribbed Bars, ISO 6935-2:2015. ISO, Switzerland.

Jin L, Liu M, Zhang R, et al., 2020. Cracking of cover concrete due to non-uniform corrosion of corner rebar: a 3D meso-scale study. Construction and Building Materials, 245:118449. https://doi.org/10.1016/j.conbuildmat.2020.118449

Jin YF, Yin ZY, 2020. Enhancement of backtracking search algorithm for identifying soil parameters. International Journal for Numerical and Analytical Methods in Geomechanics, 44(9):1239–1261. https://doi.org/10.1002/nag.3059

Jin YF, Yin ZY, Wu ZX, et al., 2018. Numerical modeling of pile penetration in silica sands considering the effect of grain breakage. Finite Elements in Analysis and Design, 144:15–29. https://doi.org/10.1016/j.finel.2018.02.003

Johnson GR, Holmquist TJ, 1994. An improved computational constitutive model for brittle materials. AIP Conference Proceedings, 309(1):981. https://doi.org/10.1063/1.46199

Lv TH, Chen XW, Chen G, 2018. The 3D meso-scale model and numerical tests of split Hopkinson pressure bar of concrete specimen. Construction and Building Materials, 160:744–764. https://doi.org/10.1016/j.conbuildmat.2017.11.094

MOHURD (Ministry of Housing and Urban-rural Development of the People’s Republic of China), 2010. Code for Design of Concrete Structures, GB 50010-2010. China Architecture Publishing & Media Co. Ltd., China (in Chinese).

Naderi S, Tu WL, Zhang MZ, 2021. Meso-scale modelling of compressive fracture in concrete with irregularly shaped aggregates. Cement and Concrete Research, 140: 106317. https://doi.org/10.1016/j.cemconres.2020.106317

Otieno M, Ikotun J, Ballim Y, 2019. Experimental investigations on the influence of cover depth and concrete quality on time to cover cracking due to carbonation-induced corrosion of steel in RC structures in an urban, inland environment. Construction and Building Materials, 198: 172–181. https://doi.org/10.1016/j.conbuildmat.2018.11.215

Qiao D, Nakamura H, Yamamoto Y, et al., 2016. Crack patterns of concrete with a single rebar subjected to nonuniform and localized corrosion. Construction and Building Materials, 116:366–377. https://doi.org/10.1016/j.conbuildmat.2016.04.149

Samanta R, Alessandro T, Jelke D, et al., 2021. A closer look at corrosion of steel reinforcement rebars in concrete using 3D neutron and X-ray computed tomography. Cement and Concrete Research, 144:106439. https://doi.org/10.1016/j.cemconres.2021.106439

Sanz B, Planas J, Sancho JM, 2013. An experimental and numerical study of the pattern of cracking of concrete due to steel reinforcement corrosion. Engineering Fracture Mechanics, 114:26–41. https://doi.org/10.1016/j.engfracmech.2013.10.013

Šavija B, Luković M, Pacheco J, et al., 2013. Cracking of the concrete cover due to reinforcement corrosion: a two-dimensional lattice model study. Construction and Building Materials, 44:626–638. https://doi.org/10.1016/j.conbuildmat.2013.03.063

Tan BW, Okoronkwo MU, Kumar A, 2020. Durability of calcium sulfoaluminate cement concrete. Journal of Zhejiang University-SCIENCE A (Applied Physics and Engineering), 21(2):118–128. https://doi.org/10.1631/jzus.A1900588

Tran KK, Nakamura H, Kawamura K, et al., 2011. Analysis of crack propagation due to rebar corrosion using RBSM. Cement and Concrete Composites, 33(9):906–917. https://doi.org/10.1016/j.cemconcomp.2011.06.001

Unger JF, Eckardt S, 2011. Multiscale modeling of concrete. Archives of Computational Methods in Engineering, 18(3):341–393. https://doi.org/10.1007/s11831-011-9063-8

Wang B, 2018. A Model for Prediction of Time to Corrosion-induced Concrete Cover Cracking and Analysis of Meso-crack Propagation. PhD Thesis, Southwest Jiaotong University, Chengdu, China (in Chinese).

Wang B, Wang H, Zhang ZQ, et al., 2018. Analysis of nonuniform corrosion of concrete cover under mesoscopic scale. Concrete, (2):157–160 (in Chinese). https://doi.org/10.3969/j.issn.1002-3550.2018.02.040

Wang JM, Jivkov AP, Li QM, et al., 2020. Experimental and numerical investigation of mortar and ITZ parameters in meso-scale models of concrete. Theoretical and Applied Fracture Mechanics, 109:102722. https://doi.org/10.1016/J.TAFMEC.2020.102722

Wang Z, Jin XY, Jin NG, 2014. Cover cracking model in reinforced concrete structures subject to rebar corrosion. Journal of Zhejiang University-SCIENCE A (Applied Physics and Engineering), 15(7):496–507. https://doi.org/10.1631/jzus.A1300393

Wu B, Yang Y, Zhang LL, et al., 2020. Meso-scale numerical study on the non-uniform corrosion-induced cracking of confined concrete. Construction and Building Materials, 260:120463. https://doi.org/10.1016/j.conbuildmat.2020.120463

Xiong H, Yin ZY, Nicot F, 2019. A multiscale work-analysis approach for geotechnical structures. International Journal for Numerical and Analytical Methods in Geomechanics, 43(6):1230–1250. https://doi.org/10.1002/nag.2893

Xu L, Pang MW, Li XN, et al., 2020. Effect of rebar position and rebar arrangement on rust expansion laws of reinforced concrete beam. Materials Protection, 53(1):106–113 (in Chinese). https://doi.org/10.16577/j.cnki.42-1215/tb.2020.01.020

Yang J, Yin ZY, Laouafa F, et al., 2020. Three-dimensional hydromechanical modeling of internal erosion in dike-on-foundation. International Journal for Numerical and Analytical Methods in Geomechanics, 44(8):1200–1218. https://doi.org/10.1002/nag.3057

Yang XM, Yang ZB, Yang L, 2019. Relationship between corrosion rate and width of corrosion cracks in corner of concrete components with different depth of cover. Bulletin of the Chinese Ceramic Society, 38(10):3332–3338 (in Chinese). https://doi.org/10.16552/j.cnki.issn1001-1625.2019.10.043

Yang ZJ, Huang YJ, Yao F, et al., 2020. Three-dimensional meso-scale cohesive fracture modeling of concrete using a Python script in Abaqus. Engineering Mechanics, 37(8):158–166 (in Chinese). https://doi.org/10.6052/j.issn.1000-4750.2019.09.0559

Yin ZY, Jin YF, Shen JS, et al., 2018. Optimization techniques for identifying soil parameters in geotechnical engineering: comparative study and enhancement. International Journal for Numerical and Analytical Methods in Geomechanics, 42(1):70–94. https://doi.org/10.1002/nag.2714

Yin ZY, Wang P, Zhang FS, 2020. Effect of particle shape on the progressive failure of shield tunnel face in granular soils by coupled FDM-DEM method. Tunnelling and Underground Space Technology, 100:103394. https://doi.org/10.1016/j.tust.2020.103394

Zhang JH, Xiong J, 2020. Concrete cover cracking behaviors induced by the non-uniform corrosion of corner-located rebars. Journal of University of Shanghai for Science and Technology, 42(1):70–78 (in Chinese). https://doi.org/10.13255/j.cnki.jusst.2020.01.012

Zhang WP, Chen JY, Luo XJ, 2019. Effects of impressed current density on corrosion induced cracking of concrete cover. Construction and Building Materials, 204: 213–223. https://doi.org/10.1016/j.conbuildmat.2019.01.230

Zhang Y, 2003. Durability of Concrete Structures. Shanghai Scientific & Technical Publishers, Shanghai, China (in Chinese).

Zhang YL, Su RKL, 2020. Corner cracking model for nonuniform corrosion-caused deterioration of concrete covers. Construction and Building Materials, 234:117410. https://doi.org/10.1016/j.conbuildmat.2019.117410

Zhao CF, Yin ZY, Hicher PY, 2018. A multiscale approach for investigating the effect of microstructural instability on global failure in granular materials. International Journal for Numerical and Analytical Methods in Geomechanics, 42(17):2065–2094. https://doi.org/10.1002/nag.2842

Zhao YX, 2013. State-of-art of corrosion-induced cracking of reinforced concrete structures. Journal of Southeast University (Natural Science Edition), 43(5):1122–1134 (in Chinese). https://doi.org/10.3969/j.issn.1001-0505.2013.05.035

Zhu HX, Yin ZY, Zhang Q, 2020. A novel coupled FDM-DEM modelling method for flexible membrane boundary in laboratory tests. International Journal for Numerical and Analytical Methods in Geomechanics, 44(3): 389–404. https://doi.org/10.1002/nag.3019

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (Nos. U1934213 and 51878572)

Contributors

Zhi-qiang ZHANG designed the research. Zhi-qiang ZHANG and Yong-long LI wrote the first draft of the manuscript. Xing-yu ZHU processed the corresponding data and completed the visualization of data. Xin-hua LIU realized the secondary development of ABAQUS and organized the manuscript. Zhi-qiang ZHANG revised and edited the final version.

Conflict of interest

Zhi-qiang ZHANG, Yong-long LI, Xing-yu ZHU, and Xin-hua LIU declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, Zq., Li, Yl., Zhu, Xy. et al. Meso-scale corrosion expansion cracking of ribbed reinforced concrete based on a 3D random aggregate model. J. Zhejiang Univ. Sci. A 22, 924–940 (2021). https://doi.org/10.1631/jzus.A2100304

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2100304