Abstract

Restraining the expansion of expansive concrete with embedded rebars can exert chemical prestressing, which may affect the durability of concrete structures. This study aims to investigate the durability performance of expansive concrete by understanding the mechanism of air permeability changes while considering the variations in reinforcement arrangements and concrete dimensions. The Torrent’s air permeability test was used to non-destructively evaluate the disparity in air permeability changes of expansive and normal concrete during the drying processes from 28 to 182 days. Additionally, expansive strain changes were continuously monitored to investigate chemical prestress. The experimental test results suggest the immense effect of the change in expansive strain on the air permeability of concrete. This study proposes that the change in microstructure owing to the loss of expansive strain may cause an increase in air permeability. The loss of expansive strain is a distinguished feature that differentiates the mechanism of air permeability changes in expansive and normal concrete. These findings suggest the possible improvement in the durability performance of expansive concrete in cases where the loss of its expansive strain can be controlled.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Shrinkage is a typical phenomenon in concrete and is considered an important problem as it affects the durability of concrete structures. One of the main reasons for concrete shrinkage is the change in moisture within the concrete [1, 2], either by self-desiccation or drying owing to evaporation [3, 4]. These types of shrinkage are respectively known as autogenous and drying shrinkages. Over time, shrinkage may lead to the formation of cracks in concrete [5]. Concrete cracking may severely threaten the durability of structural concrete members by increasing permeability and allowing dangerous substances to penetrate the concrete [6,7,8].

Adding expansive additives (EAs) to concrete mixtures is a possible solution to this shrinkage problem [9, 10]. These chemical substances were introduced in the 1930s [11] and have been extensively used in the concrete industry since then. Three types of expansive additives are used in concrete: one of them is type-K or ettringite-based EA. The EA type-K contains calcium sulfoaluminate (CSA) and calcium sulfate, which produce ettringite upon reaction and induce expansion in the concrete [12, 13]. Previous studies have suggested that adding CSA increases the early strength owing to its higher reactivity [14] and enhanced durability against sulfate and carbonation [15, 16]. Moreover, CSA is an environmentally friendly material that emits less carbon dioxide during production [17, 18].

According to Japanese standard specifications, expansive concrete can be classified into two types based on the restrained expansive strain [19]: shrinkage-compensating (150–250 × 10−6) and chemical-prestressing concrete (200–700 × 10−6). Chemical prestressing is generated by restraining the expansive energy from concrete [20, 21]. In particular, confinement played two crucial roles in restraining the expansion and shrinkage of concrete in the subsequent days. Without confinement, the expansive concrete suffers from decreased compressive strength owing to the loosened microstructure [22]. Some studies reported that restrained expansion improves concrete microstructure and crack resistance [23, 24]. These properties can be associated with the durability of concrete. One study indicated improvements in frost and carbonation resistance of expansive concrete under restrained conditions [25]. The dosage of EA in concrete must be adjusted because an excessive amount of EA may result in the formation of microcracks, thus degrading performance [26, 27]. The Japanese standard specifications recommend an EA dosage in concrete mixtures in the range of 30–60 kg/m3 to produce chemical prestress [19].

Furthermore, the composition of the concrete materials and the confinement ratio affect chemical prestress. The chemical prestress in concrete is calculated using Eq. (1).

where σ is the chemical prestress (MPa), ρ is the reinforcement ratio, Ɛ is the strain of the specimen (m/m), and Es is the Young’s modulus of the steel reinforcement (MPa).

Based on Eq. (1), the chemical prestress can be increased by adjusting the reinforcement ratio. However, the increase in reinforcement ratios may simultaneously reduce the maximum expansion in the concrete [21, 28].

The durability of concrete is well associated with the transport mechanism through the pore structure [29, 30]. In concrete engineering, durability indicators are defined as the parameters representing the resistance against the ingression of deteriorating agents [31, 32]. Of all the existing durability indicators, gas permeability has higher sensitivity with the pore-size parameter [33]. The advantage of employing gas permeability as a durability indicator is its excellent correlation with other parameters, such as water absorption, ion diffusivity, and carbonation resistance [34]. Gas permeability tests are generally categorized into laboratory- and site gas-permeability tests [33]. Previous authors confirmed the ability of the non-destructive site-gas permeability test, such as the Torrent’s method, to assess the penetrability of concrete cover and the remarkable correlation with the results of similar specimens conducted in the laboratory with controlled conditions [35, 36].

Although the effect of chemical prestress on mechanical performance has been investigated extensively, studies on its effect on durability performance are relatively limited. Among them, a previous study assessed the effect of chemical prestress on the durability and strength of expansive concrete by examining the curing conditions and water-to-binder ratios and compared it with normal concrete [37].

This study assesses the durability of chemically prestressed concrete using a non-destructive test to measure its air permeability indices by focusing only on the effects of curing conditions, w/b, and the dosage of EA. Theoretically, the chemical prestress of expansive concrete is also affected by several factors, including the size of the specimens, restrained conditions, and reinforcement ratios within the concrete. Furthermore, the size effect, represented by the volume-to-surface area ratio of concrete (V/S), is known to influence the drying progress [38,39,40]. Although several studies have discussed the effects of reinforcement ratios and directions on expansive strains [41, 42], to the best of the authors’ knowledge, no study has investigated the potential effects of these parameters on durability performance. Additionally, the discussion related to the detailed mechanism explaining the difference in the durability performance of expansive and normal concrete is still limited.

Therefore, this study investigates the durability of chemically prestressed expansive concrete during the drying process. In particular, the effects of the specimen size, confinement conditions, and reinforcement ratios on the air permeability were investigated considering changes in the expansive strain of various specimens during the drying process (for 182 days). For a detailed discussion, the effect of surface moisture during the permeability measurement was minimized using the correction method proposed by Bueno et al. [43]. In addition, the features of the air permeability change in expansive concrete during the drying process are discussed and the generated results are compared with those obtained from a previous study on normal concrete [44]. Finally, a mechanism for the change in the air permeability of expansive concrete, which distinguishes the unique behavior of expansive concrete, is newly proposed considering the effects of moisture and chemical prestress.

The materials, mix proportions, and testing methods utilized in this study are explained in Sect. 2. The experimental results are presented in Sects. 3.1–3.3, and the analysis and discussion regarding the correlations between variables such as reinforcement ratios, arrangements, and dimensions on air permeability indices are presented in Sect. 3.4. Section 3.5 discusses the effect of expansive strains and chemical prestresses on the changes in air permeability. Section 3.6 proposes the mechanism behind the change in expansive concrete's air permeability. Finally, Sect. 4 concludes this study.

2 Materials and methods

2.1 Materials and mix proportions

The materials used to cast the concrete specimens in this study are listed in Table 1. Expansive concrete with a binder containing ordinary Portland cement (OPC) and CSA-based EAs were used. The oxide compositions of the binders are listed in Table 2. Crushed quartz porphyry sand and rhyolitic gravel of different sizes were used as concrete aggregates.

In this study, expansive concrete with a w/b of 40% was cast to replicate the precast concrete products. The mixing proportions of the expansive concrete are listed in Table 3. The EA was applied to substitute 60 kg/m3 of OPC and induce expansion in the concrete. This amount was selected based on the results of a previous study [45] and was within the recommended range for developing chemically prestressed concrete according to Japanese standard specifications [19]. Fresh concrete properties were conditioned to have 8 ± 2 cm of slump and 4.5 ± 1.5% of air volume.

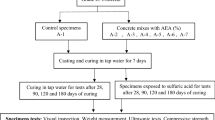

2.2 Specimen types and reinforcement arrangement

Three different types of specimens were cast during this study: prisms with (99.5 × 99.5 × 360 mm) and without (100 × 100 × 400 mm) steel rods as confinement and wall (1200 × 600 × 200 mm), as indicated in Fig. 1a–c. The prism with a steel rod is a standard specimen used to measure restrained expansive strain as specified in the Japanese Industrial Standards (JIS A 6202, Appendix 2 [46]). The prism specimen without rods is a typical specimen used to measure volumetric changes in concrete, such as drying shrinkage and free expansion. Meanwhile, inside the wall specimens, various rebar arrangements with different rebar diameters were implemented to investigate the effects of reinforcement ratios and confinement dimensions on the air permeability performance of the concrete. The details of each specimen are listed in Table 4, while the reinforcement details of the wall specimens are shown in Fig. 1d and e.

Fresh concrete was ordered from a ready-mix batching plant to accommodate the large volume of concrete required. For the prism specimens (with and without rods), concrete casting adhered to the JIS A 6202 [46] and JIS A 1132 [47], where the concrete was separated into two layers, and each layer was tamped 40 times with a steel compacting rod. For the wall specimens, concrete was placed inside the frameworks through the top surface of 1200 × 200 mm in four equal layers. Each layer was compacted using a concrete vibrator. The top surfaces were prepared after an hour to reduce bleeding.

All specimens were seal-cured with aluminum tape to maintain the moisture and placed indoors before being demolded after 7 days. P(0–0–0) was demolded after 24 h, and all the surfaces were sealed with aluminum tape for 7 days. After 3 weeks, the wall specimens were rotated to place the bottom surface on the upper side. This step was necessary to measure air permeability measurements on the bottom surface. The room temperature and relative humidity (RH) were not controlled. However, the temperature and RH were continuously monitored, and the average values during measurements were 16.1 °C and 63.1%RH.

2.3 Strain measurements and chemical prestress

The restrained strains of specimen P(1–0–0) were evaluated based on changes in the length of the steel bars. This measurement method was slightly modified from the recommended method based on dial-gauge instruments specified in JIS A 6202 [46, 48]. In this study, two 5 mm strain gauges (FLAB-5-11, Tokyo Measuring Instrument Laboratory) were set in the middle span of the reinforcement steel bars with a thermocouple to record the internal temperature inside the concrete. The strains were continuously monitored for 182 days using a data logger.

The free-expansive strain of specimen P(0–0–0) was recorded using a strain transducer KM-100BT (Tokyo Measuring Instrument Laboratory) embedded at the center of the prism specimen until 182 days. The strain transducer was equipped with a thermocouple to measure the internal temperature of the concrete.

Strain measurements of the wall specimens along the x, y, and z axes (see Fig. 1c) were conducted using the same method as that used for P(1–0–0). For the strain measurement in the x direction, two longitudinal rebars at the middle height were selected and a 5 mm strain gauge was positioned at the center of each rebar. The measurement in the y and z directions followed the same principle by attaching strain gauges at the outer part of two rebars with respect to each orthogonal direction near the middle span of the concrete. The position of the strain gauges is shown in Fig. 1c. The strain data in the x, y, and z directions were obtained from the average of at least two strain gauges attached in reinforcement located in each direction. The thermocouple was also set in the center of each wall specimen. The chemical prestress of each specimen was calculated using Equation 1. The results vary based on the restrained expansive strain data at the specific ages.

2.4 Air permeability and surface moisture measurements

Considering the existing durability indicators, site gas permeability assessment has advantages regarding the sensitivity against pore size measurements and the practicability of assessing the concrete permeability of existing structures [33]. One of the examples of site gas permeability is the Torrent’s air permeability test, an indicator to non-destructively measure the quality and penetrability of a surface concrete layer [49, 50]. The assessment of the surface-air permeability-test outputs can be challenging considering the relation with the bulk gas permeability and the scattered results in the measurement, especially with smaller spacing tools, as indicated in the instrument with a spacing of 1–5 mm [51]. However, the Torrent’s air permeability test evaluated the airflow change within the diameter of 50 mm, with expected small scattering results. Previous studies have suggested a strong correlation between the measured air permeability coefficients by Torrent’s method and other durability parameters such as carbonation, water sorptivity, and chloride resistance [52,53,54,55,56].

Air permeability measurements in this study were conducted using a PermeaTORR AC instrument (Materials Advanced Services) at 28, 56, 91, 126, 155, and 182 days based on the Torrent’s double chamber method [49], according to the Swiss standard [57]. The method monitors the pressure change in an inner chamber, 50 mm in diameter, after a vacuum period during measurement for 6 min and then calculates the coefficient of air permeability (kT) based on the formula presented in Eq. (2) [33]. The results of the Torrent’s air permeability test can be correlated with the apparent air permeability in field based on the numerical approach [36]. However, in this study, the analyses were conducted based on the direct measurement results of Torrent’s air permeability.

where kT is the coefficient of air permeability (m2), Vc is the volume of the inner test chamber pneumatic system (m3), A is the area of the inner test chamber (m2), µ is dynamic viscosity of air (N s/m2), ε is open porosity of the concrete (default value 0.15), Pa is atmospheric pressure (N/m2), ∆P is the increase of effective pressure in the inner chamber between time t0 and tf (N/m2), t0 is the time when the increase of pressure measurement started (s), and tf is the time (s) when the test is finished.

Measurements were conducted by placing the active cells of the instrument on the specimen surfaces. For the prism specimens, either P(1–0–0) or P(0–0–0), kT was calculated based on the geometric mean of the four measurement points on the side surfaces of the specimens. For the wall specimens, air permeability indices (kT) were obtained from the geometric means of six points on the 1200 × 600 mm side surfaces (xy-plane), four points on the 600 × 200 mm side surfaces (yz-plane), and three points on the 1200 × 200 mm bottom surfaces (zx-plane). The value of kT of the top surface was not measured because its uneven surface could have affected the test results. The geometric mean was selected as a representative data outcome according to the recommendations of a previous study [58].

During the kT measurements, the surface moisture content was examined as previous studies suggested that this moisture may affect air permeability [59, 60]. In particular, surface moisture was assessed using a Tramex Concrete Moisture Encounter X5 at the exact location before kT was measured. This tool verifies the surface moisture content of the concrete based on its electrical impedance by sending an electric field from the surface to a depth of 20 mm inside the concrete [61]. The moisture content of each surface was determined by averaging the measured points.

3 Results and discussion

3.1 Strain measurements of the specimens

The strains of the specimens for up to 182 days in the x, y, and z axes are shown in Fig. 2a–c. Data fluctuations occurred because of temperature and RH, as the curing room conditions for the specimens were not controlled. The maximum expansion was recorded after sealed curing for 7 days. The general trends indicated that the maximum strain decreased as the reinforcement ratio increased. In the x-axis (direction of the main reinforcement) shown in Fig. 2a, the P(0–0–0) specimen without reinforcement displayed the highest free expansion (maximum of 406 µ), and the maximum restrained strain of specimens with reinforcement decreased (from 243 to 186 µ) as the concrete reinforcement ratios increased (from 1 to 2.5%). The W(1–0–0) and P(1–0–0) specimens, which contained the same reinforcement ratios, showed relatively similar maximum strains, regardless of the size of the specimens. In addition, W(2.5–0–0), W(2.5–1–0), W(2.5–1–0.2), and W(2.5–0.4–0.2) with the same main (longitudinal) reinforcement ratios but different transverse reinforcement ratios yielded similar expansive strains on the x-axis. These results indicate that the transverse reinforcement arrangements made insignificant contributions to the strain of the main reinforcement, as previously reported by Tsuji [62].

All specimens experienced a strain decrease associated with drying shrinkage soon after they were demolded. The shrinkage progress was affected by V/S, as suggested in previous studies [63, 64]. The comparison between P(1–0–0) (red) and W(1–0–0) (solid black) (both had similar main reinforcement ratios (ρx)), suggests that P(1–0–0) has a higher shrinkage rate. This result was because P(1–0–0) had a lower V/S ratio (which implies a larger surface area), allowing enhanced moisture evaporation. Meanwhile, a higher reinforcement ratio resulted in a lower shrinkage. In comparison, the wall specimens with a reinforcement ratio of 2.5% exhibited the same shrinkage trends regardless of the reinforcement arrangement. After 126 days (~ 4 months), the concrete strains became stable, and all wall specimens recorded similar strains, irrespective of the reinforcement arrangements and sizes of the rebars.

The effect of the reinforcement direction on the strain properties is visible on the y- and z-axes, as shown in Fig. 2b and c. Based on the comparison of W(2.5–1–0), W(2.5–1–0.2), and W(2.5–0.4–0.2), the strain measurements along the y- and z-axes were higher than the strain along the x-axis, especially for specimen W(2.5–0.4–0.2). This behavior could be associated with the lower confinement ratio on the y- and z-axes, which resulted in higher recorded strains. Interestingly, the strains at the y- and z-axes of specimen W(2.5–0.4–0.2) are higher than those in P(0–0–0). The calculation of the expansion work per unit volume [65] on W(2.5–04–0.2) indicated that a similar work magnitude occurred in the x, y, and z axes (97 MPa).

3.2 Surface moisture of concrete

Figure 3 shows the measurement results of the surface moisture content from 28 to 182 days with the addition of RH (daily measurements and moving average). The measured values show the moisture content of the surface concrete layer up to a depth of approximately 20 mm [61]. From 28 to 126 days, the surface moisture continuously decreased and was in the range of 4.0–5.8%. However, after 126 days, the measured results indicated an increased moisture content. This phenomenon can be explained by the increase in the RH in the room, as shown in Fig. 3a. The effects of the reinforcement arrangement on the surface moisture content of the specimens were insignificant. In general, the specimens with lower V/S values exhibited faster drying, as indicated by P(0–0–0). By contrast, P(1–0–0), which has a similar size, displayed higher surface moisture than P(0–0–0). The different exposure conditions may explain this behavior. Confinement in the P(1–0–0) specimen only allowed the drying of the four surfaces, as both corners were enclosed with steel plates. The measurement results for the different surfaces were similar, except for those of the yz-plane side surface. The measurements of this surface were conducted at the bottom parts of the specimens. Because the rotations of the bottom parts were performed after 3 weeks, differences in the progress of the drying processes on the bottom surfaces may exist. However, after 126 days, all surfaces displayed comparable surface moisture values during the measurements.

3.3 Air permeability of concrete

The air permeabilities (kT) of the specimens from 28 to 182 days are shown in Fig. 4. The results indicate that kT increased over time as drying progressed [66]. The confinement conditions affected the kT measurements as higher ratios reduced kT; the P(0–0–0) specimen yielded the highest kT values among all the specimens. The effects of the reinforcement ratios are visible when the kT of wall specimens are compared. In particular, W(1–0–0) (ρ = 1%) yielded slightly higher kT values than those with the higher reinforcement ratio (ρ = 2.5%). Meanwhile, the effect of the confinement arrangement on air permeability was insignificant, as W(2.5–0–0), W(2.5–1–0), W(2.5–1–0.2), and W(2.5–0.4–0.2), which contained different arrangements, yielded similar air permeabilities. This result suggests that the reinforcement ratio affects kT more than the reinforcement arrangement.

The V/S ratio notably affected the air permeability performance of concrete. Comparing W(1–0–0) and P(1–0–0) with the same reinforcement ratios yielded a noteworthy difference in the kT results. The air permeability data mirror the strain measurements in Fig. 2 rather than the surface moisture content in Fig. 3a (where the outcome of these two specimens differed). The details are discussed in Sect. 3.5.

Based on Fig. 4, the kT values for the different surfaces are almost comparable. The contrast was based only on the results of kT at 28 days. The measured results for the 1200 × 200 surface (Fig. 4b) show a smaller kT than those for the other surfaces. The lower kT values could be associated with the higher surface moisture content [59, 60] of the 1200 × 200 surface, as shown in Fig. 3b. Because the kT values at different surfaces were similar, for the analysis, they were recalculated based on the geometric mean of kT on various surfaces, as shown in Fig. 5.

3.4 Compensation for surface moisture effects on measured air permeability in concrete

The relationship between the surface moisture content and the air permeability index of concrete is shown in Fig. 6. The general trend indicates that kT decreases as surface moisture increases. This trend is consistent with the results in previous studies [35, 43, 59]. The relationship between moisture and air permeability in this study was almost linear and similar to that in [43]. However, in detail, the values of the exponent (δ) of the regression analysis (1.86–3.21) were larger than the median in the previous study (1.45), and the correlation coefficients were lower (see Appendix 1).

To minimize the effect of moisture content blocking the airflow in the measurements, the kT5 values of the specimens were calculated based on the equation introduced by Bueno et al. [43]. This method corrects the measured kT to the values when the moisture is 5%, which is the typical surface moisture of concrete at 1–3 months. Equation (3) was used to calculate kT5 [41],

where kT5 is the kT value when the moisture is 5% (× 10−16 m2), and kTm is the kT value measured when the moisture is m (%).

This calculation procedure was validated using the measured results of normal concrete specimens with several types of supplementary cementitious materials, such as slag, fly ash, silica fume, and limestone filler, but without expansive additives. Although kT5 was introduced recently, a previous study [53] indicated the effectiveness of this parameter in predicting the carbonation rate of concrete.

The calculated kT5 values for each sample at various ages are illustrated in Fig. 7. After compensating for the surface moisture effect, kT5 yields relatively stable values but slightly increases during the drying process. This behavior may be the most crucial information in Fig. 7 because of the unique behavior of expansive concrete. Based on the correction method with validation data of normal (non-expansive) concrete from Bueno et al. [43], kT5 should be stable once the moisture effect is reduced. However, the figure shows an increase in the kT5 values of the specimens, especially from 28 to 91 days. The results are related to the higher values of the exponent of the regression analysis shown in Fig. 6 and the Appendix 1. These results may indicate that expansive concrete behaved differently from normal concrete during the drying process. The disparity in kT5 behaviors could be associated with changes in the microstructural properties owing to the loss of chemical prestress, as suggested by the change in strains or microcracking related to excessive expansion [37]. The discussion regarding these results is presented in the following section.

3.5 Relationships between kT 5 and expansive strain and chemical prestress of the expansive concrete

Microstructural changes in concrete can be assessed based on several parameters; one study suggested the use of strain to understand the change in performance [67]. Therefore, Fig. 8a and b show the relationship between kT5 and expansive strain (Ɛx) and the change in the expansive strain (ΔƐx) at different ages. ΔƐx was calculated from the subtraction of strain at a particular time and the maximum expansive strain recorded. Chemical prestress was generated exclusively by restrained expansive concrete. Furthermore, several authors have suggested the effects of chemical prestress on the microstructural performance of concrete [13, 68]. Based on this suggestion, the chemical prestress effect on air permeability was considered by investigating the relationship between the chemical prestress (σCP) and the chemical prestress loss (ΔσCP) with kT5. The results are displayed in Fig. 8c and d. ΔσCP was calculated based on the differences between the maximum values and the chemical prestress values at particular times.

Figure 8a shows that kT5 increases as the expansive strain decreases, thus suggesting performance degradation owing to shrinkage. However, the trends of the unconfined and confined specimens should be analyzed separately. Figure 8b indicates that there is a good correlation between ΔƐx and the air permeability data (kT5), as shown by the relatively high R2 values (0.776). By contrast, the graph also includes data from unrestrained specimens.

Figure 8c and d indicate that the air permeability increases as the chemical prestress decreases, which could explain the positive effect of chemical prestressing on concrete. When parameter ΔσCP was used, the correlation with kT5 could be separated based on the confinement ratios. The specimens restrained along one dimension (W(1–0–0) and P(1–0–0)) yielded a better correlation with kT5 compared with the other specimens. However, the chemical prestress parameter could not explain the behavior of the unrestrained specimens because of the general assumption that no chemical prestress was generated.

The relationship between kT5 and the indices for microstructural changes shows that parameter ΔƐx exhibits the best correlation in Fig. 8. Air permeability increased as the shrinkage progressed. A possible reason for the best correlation with ΔƐx is that ΔƐx could describe the exact change in microstructural properties owing to the loss of expansive strain induced by the expansive additive reaction. Figure 8b also suggests an existing value of kT5 that is not affected by the surface moisture contents and expansive strain changes in the expansive concrete at the intersection of the extended regression curve and vertical axis (~ 0.001 × 10−16 m2). This finding is discussed in the following section. The change in expansive strain strongly correlated with the total moisture loss in the concrete [69, 70]. Moreover, the moisture loss parameter represented by the strain data could also explain the difference between the air permeabilities of P(1–0–0) and W(1–0–0) in Sect. 3.3, as P(1–0–0) displayed a higher strain loss than W(1–0–0).

3.6 Changes in air permeability of expansive concrete during the drying process

This section discusses the possible leading factors affecting the measured air permeability coefficient in expansive concrete as a function of the drying period, as shown in Fig. 9. This concept was inspired by the findings of Bueno et al. [43] while considering the special behavior of the expansive concrete determined in this study. In general, the measured air permeability of concrete was strongly affected by changes in surface moisture [59, 60], as shown in Fig. 6. In particular, Fig. 9a shows the decrease in moisture, especially during drying, which is affected by the V/S ratio. A smaller V/S, which can be correlated with a slower drying process, results in higher moisture content in the concrete [63, 64].

Expansive concrete has unique properties that affect its air permeability measurements. The expansive strain of concrete may decrease over time because of drying. When the occurrence of the microcracks induced by the addition of EA [37] is coupled with the loss of chemical strain (ΔƐ) generated by the expansion could worsen the microstructure of the concrete. The discussion in Sect. 3.1 indicated that the V/S ratio and the rebar ratios affect the change in the strain of the expansive concrete, as shown in Fig. 9b. Based on the results of this study, smaller V/S and rebar ratios could lead to higher losses in chemical strain. Moreover, V/S was a dominant factor over the rebar ratio.

Figure 9c illustrates the distinctive features of the air permeability measurement of the expansive concrete compared with normal concrete. The two and three lines in the figure qualitatively show the features of normal and expansive concrete. We assumed the fundamental air permeability (kTf) to be constant after eliminating the moisture effect, and its associated factors changed the measured kT during the drying process. That is, kTf yields the ideal air permeability at reference surface moisture content (= 5%) without the effect of the expansive strain loss.

The two reference lines for normal concrete were prepared based on the results shown in Appendix 2, which included similar conditions (water-to-cement ratio (w/c) of 35%, seal cured for 5 days, and plain concrete without rebars) in a previous study [44]. In the case of normal concrete, kT5 calculated using Eq. (3) exhibited an almost constant value (~ 0.1 × 10−16 m2) regardless of the drying period, which can be defined as the constant kTf value of normal concrete. In other words, the increase in the measured kTm during drying can be explained by the decrease in surface moisture which blocked the airflow in the pores.

For the expansive concrete studied herein, the increase in kT can be explained by using three lines with two factors in the figure: the increase from kTf (black line) to kT5 (red line) can be explained by the coarser microstructure which results from the loss of chemical strain, and the additional increase in kTm (blue line) can be explained by a decrease in pore saturation due to the loss of free water. The former factor is the same as that induced in normal concrete, whereas the latter factor was newly discovered in the discussion of expansive concrete in Sect. 3.5. The value of kTf is calculated using the regression formula in Fig. 8b, based on the assumption that the loss of chemical strain is close to zero. The kTf value of the expansive concrete in this study (~ 0.001 × 10−16 m2) was much smaller than that of normal concrete, whereas the measured kTm after drying of the expansive concrete was almost the same or slightly larger than that of normal concrete. These results reveal the significant contribution of the expansive strain to the air permeability of expansive concrete. Furthermore, the results suggest that expansive concrete may have improved quality compared with normal concrete if the loss of the expansive strain can be reduced against drying.

Detailed comparisons of normal and expansive concrete (kTm, kT5, and kTf) are presented in Appendix 2.

4 Conclusions

This study investigated the durability performance of expansive concrete through the assessment of air permeability changes considering the effects of the specimen size, reinforcement ratio, and reinforcement arrangement. The mechanism of air permeability changes, which differentiate normal and expansive concrete, was discussed using three types of air permeability coefficients: measured kTm, moisture-compensated kT5, and fundamental air permeability kTf without time-dependent effects. The following conclusions were drawn from the results.

-

1.

The kT5 of the expansive concrete differed from that of normal concrete. kT5 increased over time, particularly from the 28th to the 91st day. This could be associated with a change in the microstructure owing to chemical prestress loss or microcracking related to excessive expansion.

-

2.

V/S affected the kT5 values of the concrete, as smaller-sized specimens possessed a higher kT5 value than larger specimens. This could be associated with the faster drying of smaller specimens, which further increased the loss of chemical strain.

-

3.

The effect of reinforcement arrangement on the air permeability of expansive concrete is trivial. Moreover, the reinforcement ratio contributes more to the restraining of the shrinkage progress than directly affecting the permeability properties of the concrete.

-

4.

Unlike the change in permeability of normal concrete, which is only affected by the moisture, expansive concrete suggested a more complicated mechanism for determining air permeability. The air permeability of expansive concrete increased with the decrease in surface moisture and higher loss of expansive strain (ΔƐ).

-

5.

This study suggested the better durability characteristics of expansive concrete compared with normal concrete. The kTf value of the expansive concrete was lower than that of the normal concrete, thus suggesting an improved initial performance of the expansive concrete. The durability of expansive concrete can be preserved if the loss of expansive strain can be controlled.

This study described the changes in the air permeability of expansive concrete. A comparison with normal concrete indicated significantly better durability in cases in which the expansive strain could be maintained during the drying period. This finding might suggest that combining the expansion additive with methods to preserve the expansive strain, such as employing shrinkage-reducing agents (SRAs) or increasing the reinforcement ratios, can be a sufficient way to improve the durability performance of expansive concrete. This hypothesis should be investigated in future studies. Furthermore, the concept of fundamental kT (kTf) could be a crucial parameter for determining concrete durability in the future. Currently, this study suggests that predicting air permeability indices using parameters such as the reinforcement ratio, V/S, and strain of the concrete is possible. To reveal the physical mechanism of the obtained correlations and establish a prediction equation, more comprehensive studies with various mixture proportions (i.e., w/b and EA content), specimen dimensions, rebar arrangement, and curing conditions are necessary. Additionally, direct evidence of the effect of expansive strain should be demonstrated by observing pore structure changes through microstructural analysis, such as electron microscopy and mercury intrusion porosimetry. Lastly, the correlation between the current assessment using Torrent’s and apparent air permeability of expansive concrete should be addressed to compare the behavior of expansive concrete.

References

Sakata K (1983) A study on moisture diffusion in drying and drying shrinkage of concrete. Cem Concr Res 13:216–224. https://doi.org/10.1016/0008-8846(83)90104-7

Kovler K, Zhutovsky S (2006) Overview and future trends of shrinkage research. Mater Struct/Mater Constr 39:827–847. https://doi.org/10.1617/s11527-006-9114-z

Persson B (1997) Self-desiccation and its importance in concrete technology. Mater Struct/Mater Constr 30:293–305. https://doi.org/10.1007/bf02486354

Bentz DP (2008) A review of early-age properties of cement-based materials. Cem Concr Res 38:196–204. https://doi.org/10.1016/j.cemconres.2007.09.005

Zhang J, Hou D, Han Y (2012) Micromechanical modeling on autogenous and drying shrinkages of concrete. Constr Build Mater 29:230–240. https://doi.org/10.1016/j.conbuildmat.2011.09.022

Kheder GF, Al-Rawi RS, Al-Dhahi JK (1994) A study of the behaviour of volume change cracking in base restrained concrete walls. Mater Struct 27:383–392

Wang K, Jansen DC, Shah SP, Karr AF (1997) Permeability study of cracked concrete. Cem Concr Res 27:381–393. https://doi.org/10.1016/S0008-8846(97)00031-8

Hu X, Shi Z, Shi C, Wu Z, Tong B, Ou Z, de Schutter G (2017) Drying shrinkage and cracking resistance of concrete made with ternary cementitious components. Constr Build Mater 149:406–415. https://doi.org/10.1016/j.conbuildmat.2017.05.113

Zheng L, Xuehua C, Mingshu T (1991) MgO-type delayed expansive cement. Cem Concr Res 21:1049–1057. https://doi.org/10.1016/0008-8846(91)90065-P

Sun W, Chen H, Luo X, Qian H (2001) The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem Concr Res 31:595–601. https://doi.org/10.1016/S0008-8846(00)00479-8

Lossier H, Caguol A (1944) Expanding cements and their application—self-stressed concrete. Le Genie Civ (Paris) 121:61–65

Cohen MD (1983) Theories of expansion in sulfoaluminate—type expansive cements: schools of thought. Cem Concr Res 13:809–818. https://doi.org/10.1016/0008-8846(83)90082-0

Mehta PK (1973) Mechanism of expansion associated with ettringite formation. Cem Concr Res 3:1–6. https://doi.org/10.1016/0008-8846(73)90056-2

Glasser FP, Zhang L (2001) High-performance cement matrices based on calcium sulfoaluminate–belite compositions. Cem Concr Res 31:1881–1886. https://doi.org/10.1016/S0008-8846(01)00649-4

Sherman N, Beretka J, Santoro L, Valenti GL (1995) Long-term behaviour of hydraulic binders based on calcium sulfoaluminate and calcium sulfosilicate. Cem Concr Res 25:113–126. https://doi.org/10.1016/0008-8846(94)00119-J

Quillin K (2001) Performance of belite–sulfoaluminate cements. Cem Concr Res 31:1341–1349. https://doi.org/10.1016/S0008-8846(01)00543-9

Gartner E (2004) Industrially interesting approaches to “low-CO2” cements. Cem Concr Res 34:1489–1498. https://doi.org/10.1016/j.cemconres.2004.01.021

Pace ML, Telesca A, Marroccoli M, Valenti GL (2011) Use of industrial byproducts as alumina sources for the synthesis of calcium sulfoaluminate cements. Environ Sci Technol 45:6124–6128. https://doi.org/10.1021/es2005144

Japan Society of Civil Engineers (2007) Standard specifications for concrete structures—materials and construction

Tazawa E, Kawai K, Miyaguchi K (2000) Expansive concrete cured in pressurized water at high temperature. Cem Concr Compos 22:121–126. https://doi.org/10.1016/S0958-9465(99)00038-4

Wyrzykowski M, Terrasi G, Lura P (2018) Expansive high-performance concrete for chemical-prestress applications. Cem Concr Res 107:275–283. https://doi.org/10.1016/j.cemconres.2018.02.018

Nagataki S, Gomi H (1998) Expansive admixtures (mainly ettringite). Cem Concr Compos 20:163–170. https://doi.org/10.1016/s0958-9465(97)00064-4

Zdanowicz K, Marx S (2022) Flexural behaviour of thin textile reinforced concrete slabs enhanced by chemical prestressing. Eng Struct. https://doi.org/10.1016/j.engstruct.2022.113946

Wyrzykowski M, Terrasi G, Lura P (2020) Chemical prestressing of high-performance concrete reinforced with CFRP tendons. Compos Struct 239:112031. https://doi.org/10.1016/j.compstruct.2020.112031

Van ND, Kuroiwa E, Kim J, Choi H, Hama Y (2020) Influence of restrained condition on mechanical properties, frost resistance, and carbonation resistance of expansive concrete. Materials. https://doi.org/10.3390/ma13092136

Liwu M, Ming D, Mingshu T, Abir A-T (2014) MgO expansive cement and concrete in China: past, present and future. Cem Concr Res 57:1–12. https://doi.org/10.1016/j.cemconres.2013.12.007

Carballosa P, Calvo JLG, Revuelta D (2020) Influence of expansive calcium sulfoaluminate agent dosage on properties and microstructure of expansive self-compacting concretes. Cem Concr Compos 107:103464. https://doi.org/10.1016/j.cemconcomp.2019.103464

Cao Q, Li H, Lin Z (2019) Study on the active confinement of GFRP-confined expansive concrete under axial compression. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.116683

Luping T, Nilsson L-O (1992) A study of the quantitative relationship between permeability and pore size distribution of hardened cement pastes. Cem Concr Res 22:541–550. https://doi.org/10.1016/0008-8846(92)90004-F

Breysse D, Gérard B (1997) Modelling of permeability in cement-based materials: Part 1-uncracked medium. Cem Concr Res 27:761–775. https://doi.org/10.1016/S0008-8846(97)00066-5

Alexander MJ (2004) Durability indexes and their use in concrete engineering. In International RILEM symposium on concrete science and engineering: a tribute to Arnon Bentur, RILEM Publications SARL, pp 9–22. https://doi.org/10.1617/2912143586.002

Baroghel-Bouny V (2006) Durability indicators: relevant tools for performance-based evaluation and multi-level prediction of RC durability

Torrent RJ, Neves RD, Imamoto K (2021) Concrete permeability and durability performance. CRC Press, Boca Raton. https://doi.org/10.1201/9780429505652

Hilsdorf H, Kropp J (1995) RILEM TC 116-PCD: performance criteria for concrete durability

Romer M (2005) Effect of moisture and concrete composition on the Torrent permeability measurement. Mater Struct/Mater Constr 38:541–547. https://doi.org/10.1617/14321

Multon S, Verdier J, Cagnon H, Nehme A, Sogbossi H (2024) Numerical analysis of concrete permeability measurements in laboratory and in field. Cem Concr Res 178:107455. https://doi.org/10.1016/j.cemconres.2024.107455

Wijaya AL, Kajita S, Tadokoro Y, Uchino M, Nakarai K (2023) Strength and air permeability of steam-cured expansive concrete: effects of chemical prestress, water-to-binder ratio, and curing condition. Mater Struct/Mater Constr. https://doi.org/10.1617/s11527-023-02223-8

Parrott LJ (1995) Influence of cement type and curing on the drying and air permeability of cover concrete. Mag Concr Res 47(171):103–111. https://doi.org/10.1680/macr.1995.47.171.103

Ba M, Qian C, Wang H (2013) Effects of specimen shape and size on water loss and drying shrinkage of cement-based materials. J Wuhan Univ Technol Mater Sci Ed 28:733–740. https://doi.org/10.1007/s11595-013-0761-y

Wu Z, Wong HS, Buenfeld NR (2015) Influence of drying-induced microcracking and related size effects on mass transport properties of concrete. Cem Concr Res 68:35–48. https://doi.org/10.1016/j.cemconres.2014.10.018

Myint SH, Tanapornraweekit G, Tangtermsirikul S (2021) Investigation of expansive concrete structures through strain monitoring in field structures. Asian J Civ Eng 22:565–578. https://doi.org/10.1007/s42107-020-00332-1

Prayuda H, Dumaru R, Tanapornraweekit G, Tangtermsirikul S, Saengsoy W, Matsumoto K (2022) Estimation of restrained expansion strain of reinforced expansive concrete considering mixture and curing conditions. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.126386

Bueno V, Nakarai K, Nguyen MH, Torrent RJ, Ujike I (2021) Effect of surface moisture on air-permeability kT and its correction. Mater Struct/Mater Constr. https://doi.org/10.1617/s11527-021-01666-1

Nguyen MH, Nakarai K, Torrent R (2020) Service life prediction of steam-cured concrete utilizing in-situ air permeability measurements. Cem Concr Compos 114:103747. https://doi.org/10.1016/j.cemconcomp.2020.103747

Nguyen HV, Nakarai K, Okazaki A, Karasawa H, Tadokoro Y, Tsujino M (2019) Applicability of a simplified estimation method to steam-cured expansive concrete. Cem Concr Compos 95:217–227. https://doi.org/10.1016/j.cemconcomp.2018.11.002

Japanese Industrial Standard Committee (2017) JIS A 6202—expansive additive for concrete

Japanese Industrial Standard Committee (2020) JIS A 1132-Method of making and curing concrete specimens

ASTM International (2014) ASTM C878 / C878M-14a standard test method for restrained expansion of shrinkage-compensating concrete. https://doi.org/10.1520/C0878-95A

Torrent RJ (1992) A two-chamber vacuum cell for measuring the coefficient of permeability to air of the concrete cover on site. Mater Struct 25:358–365. https://doi.org/10.1007/BF02472595

Imamoto KI, Neves R, Torrent R (2016) Carbonation rate in old structures assessed with air-permeability site NDT, maintenance, monitoring, safety, risk and resilience of bridges and bridge networks. In: Proceedings of the 8th international conference on bridge maintenance, safety and management, IABMAS 2016, pp 178–184

Grover D, Savidge CR, Townsend L, Rosario O, Hu L-B, Rizzo DM, Dewoolkar MM (2016) Surface permeability of natural and engineered porous building materials. Constr Build Mater 112:1088–1100. https://doi.org/10.1016/j.conbuildmat.2016.02.193

Neves R, Da Fonseca BS, Branco F, De Brito J, Castela A, Montemor MF (2015) Assessing concrete carbonation resistance through air permeability measurements. Constr Build Mater 82:304–309. https://doi.org/10.1016/j.conbuildmat.2015.02.075

Nguyen MH, Nakarai K, Torrent RJ, Bueno V (2023) Concrete carbonation prediction based on air-permeability tests with moisture compensation. Mater Struct/Mater Constr. https://doi.org/10.1617/s11527-022-02081-w

Nguyen MH, Nishio S, Nakarai K (2022) Effect of temperature on nondestructive measurements for air permeability and water sorptivity of cover concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.127361

Jiménez LF, Moreno EI (2015) Durability indicators in high absorption recycled aggregate concrete. Adv Mater Sci Eng. https://doi.org/10.1155/2015/505423

Sakai Y (2020) Relationship between air diffusivity and permeability coefficients of cementitious materials. RILEM Tech Lett 5:26–32. https://doi.org/10.21809/rilemtechlett.2020.114

Swiss Standard (2013) SIA 262/1:2013 concrete construction-complementary specifications

Jacobs F, Hunkeler F (2006) Non destructive testing of the concrete cover-evaluation of permeability test data. In: Proceedings Pro047: International RILEM workshop on performance based evaluation and indicators for concrete durability, pp 207–214

Jacobs F (1998) Permeability to gas of partially saturated concrete. Mag Concr Res 50:115–121. https://doi.org/10.1680/macr.1998.50.2.115

Chen W, Liu J, Brue F, Skoczylas F, Davy CA, Bourbon X, Talandier J (2012) Water retention and gas relative permeability of two industrial concretes. Cem Concr Res 42:1001–1013. https://doi.org/10.1016/j.cemconres.2012.04.003

Tramex Ltd., User guide concrete moisture encounter X5, (n.d.). https://tramexmeters.com/perch/resources/cmex5-universal-online-user-guide.pdf. Accessed 5 Dec 2023

Tsuji Y (1975) Fundamental study on the use of chemical prestress in concrete. Proc Jpn Soc Civ Eng 1975:111–124. https://doi.org/10.2208/jscej1969.1975.235_111

Almudaiheem JA, Hansen W (1987) Effect of specimen size and shape on drying shrinkage of concrete. ACI Mater J. https://doi.org/10.14359/1860

Bal L, Buyle-Bodin F (2013) Artificial neural network for predicting drying shrinkage of concrete. Constr Build Mater 38:248–254. https://doi.org/10.1016/j.conbuildmat.2012.08.043

Tsuji Y (1988) Estimation of expansive energy in concrete engineering. Concr J 26:5–13. https://doi.org/10.3151/coj1975.26.10_5

Nakarai K, Shitama K, Nishio S, Sakai Y, Ueda H, Kishi T (2019) Long-term permeability measurements on site-cast concrete box culverts. Constr Build Mater 198:777–785. https://doi.org/10.1016/j.conbuildmat.2018.11.263

Cao J, Chung DDL (2004) Microstructural effect of the shrinkage of cement-based materials during hydration, as indicated by electrical resistivity measurement. Cem Concr Res 34:1893–1897. https://doi.org/10.1016/j.cemconres.2004.02.002

Zhao H, Xiang Y, Xie D, Xu W, Wang Y, Li H, Tian Q, Liu J (2020) Effects of CaO-based and MgO-based expansion agent, curing temperature and restraint degree on pore structure of early-age mortar. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119572

Bissonnette B, Pierre P, Pigeon M (1999) Influence of key parameters on drying shrinkage of cementitious materials. Cem Concret Res 29(10):1655–1662. https://doi.org/10.1016/S0008-8846(99)00156-8

Zhang W, Zakaria M, Hama Y (2013) Influence of aggregate materials characteristics on the drying shrinkage properties of mortar and concrete. Constr Build Mater 49:500–510. https://doi.org/10.1016/j.conbuildmat.2013.08.069

Acknowledgements

The experiments were conducted at Hiroshima University with the support of Mr. Toshikazu Matsuyama and students, especially Mr. Ryoga Takaoka and Mr. Shogo Kuroiwa from the Structural Engineering Laboratory of Hiroshima University. Discussions with members of the Technical Committee of the All Japan Box Culvert Association also provided valuable assistance. The authors appreciate the support of all those mentioned.

Funding

Open Access funding provided by Hiroshima University. This study was supported by the All Japan Box Culvert Association and JSPS KAKENHI (Grant number: JP22H01565).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Statistical analysis of the exponential relationship between surface moisture and air permeability (kT)

δ | R | |

|---|---|---|

P(1–0–0) | 2.28 | 0.61 |

P(0–0–0) | 2.28 | 0.82 |

W(1–0–0) | 2.88 | 0.36 |

W(2.5–0–0) | 2.62 | 0.41 |

W(2.5–1–0) | 3.21 | 0.41 |

W(2.5–1–0.2) | 2.05 | 0.43 |

W(2.5–0.4–0.2) | 1.86 | 0.43 |

Mean | 2.45 | 0.50 |

Appendix 2: Comparison of expansive concrete (water-to-binder ratio (w/b) 40%) and normal concrete N35 (water-to-cement ratio (w/c) 35%, seal cured for 5 days); kT m (a), kT 5 (b), and kT f (c)

*kTf of expansive concrete presented in Appendix 2(c) was calculated based on the equation shown in Fig. 8b.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wijaya, A.L., Nakarai, K. Changes in air permeability of restrained expansive concrete under drying condition: contribution of expansive strain. Mater Struct 57, 125 (2024). https://doi.org/10.1617/s11527-024-02401-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-024-02401-2