Abstract

The ageing of bitumen has received great attention both from a chemical and rheological perspective due to its direct impact on asphalt performance. However, open questions with respect to the convergence of the synchronous ageing changes in rheology and chemistry of bitumen still exist. This paper addresses these alterations of chemistry and rheology and attempts to establish a link via fitting rheological equations fed by fundamental chemical information. To that end, three binders of different type were used in four different laboratory ageing states. A number of spectroscopic techniques and rheological testing were employed to derive corresponding chemical and rheological parameters. In parallel, various statistical methods (Bivariate analysis, Wilcoxon test, Factor analysis) assisted in identifying relationships among the chemo-rheological parameters and simplifying the number of variables. The results of this study demonstrate that chemistry and rheology are following similar changes when considering laboratory ageing following the fast-rate phase of a dual oxidation scheme and short-term lab ageing. Finally, this work manages to establish a linking framework for a number of newly-introduced rheological parameters. All in all, the results of this study might be particularly interesting for future interventions in the chemical composition of bitumen, considering its effect on performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bitumen is undoubtedly one of the main materials for pavement construction, as it works as the basic binding medium in asphalt. Recently released data report that 85% of the annual bitumen world production (87 million tons) is used for road paving [1]. Following the fast-evolving technological and environmental trends, the alarming need for designing more sustainable and durable structures, including roads, has led towards an attitude to prolong the lifetime of materials and improve their composition in order to resist the majority of the possible deteriorative mechanisms. As such, bitumen has also generated much interest in the scientific community in an effort to understand better its performance from different physicochemical and mechanical perspectives [2, 3].

Unfortunately, there are obstacles to reach a complete understanding of bitumen’s composition and long-term performance. For example, a variety of processes take place during the production and service life of asphalt, with oxidative ageing being the most crucial as it negatively affects the pavement performance when it is not moderated [4,5,6,7]. In parallel, a plethora of additives and rejuvenating agents have been introduced with the potential to improve the bitumen’s performance or to compensate for certain irreversible chemical alterations [8, 9]. All the above make the unboxing of this complex blend of organic molecules, a difficult task for researchers worldwide as bitumen additionally varies in origin, distillation process and application [10]. It is certainly fair to consider that no matter which the additive or bitumen type is, oxidative ageing, as well as moisture and ultraviolet radiation, are certainly affecting the final performance [11, 12]. Herein, to simplify the coupled effects, the main focus will be given to the reaction–diffusion of oxygen in bitumen, widely known as ageing.

Previous research has stressed the importance of bitumen’s chemistry for its performance [13,14,15] and the necessity to bridge the different scales, from molecular to nano-, micro- and further to meso-and macroscale [16,17,18]. It remains an open question whether the fundamental chemistry and rheology in bitumen are affected at a similar level by ageing. Although theories put forward by Petersen and his colleagues [13, 19] for a dual rate-determining oxidation scheme, have been to some extent confirmed experimentally by utilising advanced spectroscopy and liquid chromatography [20,21,22], yet the evolving trends of certain chemical products in comparison with performance-related parameters need to be revealed. Many studies have focused on the association between simply derived ageing indices via Fourier-Transform Infrared (FTIR) spectroscopy which represent the oxygenated functional groups, i.e. carbonyls, and parameters essential for workability, such as viscosity [5, 23]. Similar efforts have been undertaken to link other cumulative FTIR ageing indices, i.e. sulfoxides and carbonyls, with more sophisticated rheological indices derived with a Dynamic Shear Rheometer (DSR), accounting for a single frequency or the whole range of frequencies in the area under a master curve [24, 25]. In parallel, other works have utilised the same techniques for differentiating the effects of different long-term protocols in corresponding ageing parameters [26].

Caution should be taken when the previously proposed chemical factors are employed since pairwise interactions with other oxygenated products may take place. Thus, a linear regression between a simple index of chemistry and rheology may not be realistic or suitable to predict the complete framework of ageing changes, especially in newly introduced distress-related parameters. In addition, empirical parameters i.e. penetration and softening point, have been shown to be inadequate ageing surrogates when it comes to the effect of crude source or additive presence, thus are no longer considered to be the best performance indicators [27]. Instead, advanced rheological parameters have been introduced in the last decades, which not only are associated with basic bitumen’s concepts, such as ductility and relaxation but also with distress phenomena and concepts of durability, rutting and thermal-cracking [3, 8, 27,28,29,30].

It appears that in order to examine the correspondence of the intensity of the ageing products and the simultaneous evolution of advanced rheological indices, extensive fundamental information of chemistry is needed besides the oxygenated FTIR functional groups. Of particular complexity is to incorporate parameters such as the organic radicals which have been shown to play a crucial role in the continuation of ageing, in a potential ageing predictive scheme [13, 22]. Furthermore, the formation or consumption of intermediate and final chemical products need to be taken into account in possible linking equations of bitumen’s rheological performance. One able to implement in a scheme all these factors will have at least a fair overview of the bitumen’s chemistry so that controlled conclusions can be drawn for the corresponding changes of rheology.

Different lab simulation protocols have been also proposed during the years for the ageing of bitumen with the most common ones, being the Rolling Thin Film Oven (RTFO) [31] and the Pressure Ageing Vessel (PAV) [32]. It is still a matter of debate if these standardised protocols simulate in a similar manner the ageing in-situ, not only in terms of performance but also in terms of chemistry, as other factors i.e. humidity, ultraviolet light, reactive oxygen species may affect differently the reaction routes [33]. Previous works have shown that incorporating such factors can approximate better the ageing in the field both from a chemical and rheological perspective [34]. Other alternatives of oxidation in thin bitumen films under constant conditions at different time intervals offer the advantage of kinetic studies and have been proven appropriate to track the time evolution of ageing chemistry and the transition point of the rate-determining phases [21, 35]. For this transition point in kinetics, it is still uncertain whether also chemistry would converge if similar rheological performance with standardised protocols can be obtained.

Hence, the aim of the current work is twofold. On one hand, this study addresses the open question of whether chemistry and rheology follow the same laboratory ageing trends independent of the conditions of the laboratory ageing protocol which is used and, on the other hand, aims to provide a statistical linking framework for advanced rheological parameters using fundamental chemistry of bitumen as input. To that end three different bituminous binders differing in crude source, distillation and penetration grade were examined to compare their changes in rheology and chemistry. Four different laboratory ageing states (original state, two standardised and one time interval of kinetics) are also utilised with the primary goal to reveal possible simulation-related differences in bitumen’s chemistry and rheology. Next, fundamental information derived from advanced spectroscopy such as Electron Paramagnetic Resonance (EPR), Time of Flight-Secondary Ion Mass Spectrometry (TOF-SIMS), Proton Nuclear Magnetic Resonance (1H-NMR) and FTIR is used as input in a statistical framework. The Wilcoxon exact test and the Pearson’s r of a bivariate analysis are used as metrics for the equivalence of the properties between standardised ageing and the reaction-rate transition point in kinetics. The study is additionally designed with the optimum goal to account for the DSR extracted rheological parameters of R, ΔΤc, Glover-Rowe, crossover values and viscosity, analysed in detail in the following section. Employing multivariate statistics by means of sample correlation matrix and factor analysis, the number of original chemical and rheological variables is reduced and further implemented into fitting equations of rheology as a training dataset, using a so-called factor analysis regression. This work finally stresses the goodness of existing fit between the latent variables of chemistry and the advanced parameters of rheology.

2 Materials and methods

2.1 Materials

Three bituminous binders were used in this study and their basic properties are shown in Table 1. The binders were selected to differ in terms of origin, distillation process, wax presence and penetration. The reader is referred to previous works for the complete details of each binder [21, 22]. In brief, bitumen A and B are from the same crude whereas bitumen C is a waxy, visbroken binder from a different crude source.

2.2 Laboratory ageing protocols

Laboratory ageing was performed according to the standard protocols for short- and long-term ageing, EN 12607-1 and EN14769 respectively [31, 32]. Previous kinetic studies with these binders [21, 35], used a modified thin film oven test (M-TFOT) of 1 mm film thickness at 50 °C. The suggested protocol is a modified version of the standardised EN 12607-2 but it uses different extended time intervals and a considerably lower temperature. In the initial investigation, the binders were aged with this modified protocol up to 56 days at different time intervals; oxidation kinetics were studied and revealed that the completion of the fast-rate oxidation phase and the initiation of the slow-rate oxidation phase for all the three binders was found to be at 8 days. This time interval was additionally used to evaluate the chemical and rheological level of this transition point between the two rate-determining phases with standard lab protocols. For reference purposes, the chemo-rheological properties of the fresh binders were also used for all the following analyses and testing. In all the subsequent sections the binder designation is followed by the laboratory ageing simulation used whereas all the parameter values are the average of two replicates for the rheological and three replicates for the chemical values. An overview of the research approach followed for this study is illustrated in Fig. 1.

2.3 Chemical analyses

2.3.1 Fourier transform infrared (FTIR)

A Thermo Scientific Nicolet iS10 Attenuated Total Reflectance (ATR)-FTIR spectrometer was used in this study for the calculation of indices related to the processes of oxidation and aromatisation in bitumen. The FTIR spectrometer is employed with a diamond ATR crystal, where bituminous samples were placed as a workable droplet which was allowed to cool down for 5 min for the standardised simulations and as a cold film for the M-TFOT. Spectra were obtained in the 400–4000 cm−1 wavenumber range, 4 cm−1 resolution, with 32 scans, prior to background recording per sample. Processing of the spectra was performed based on a one-step normalization which corresponds to the ratio of the area under investigation over a sum of constant areas [21, 37]. The carbonyl (COI), sulfoxide (SOI), and aromaticity (ARI) indices were eventually utilised for all the ageing states.

2.3.2 Electron paramagnetic resonance (EPR)

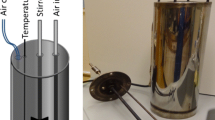

A Bruker Elexsys E680 (X/W) Continuous-wave (CW) EPR spectrometer at X-band was employed for the evaluation of the number of spins of carbon-based organic radicals (CBOR) and vanadyl centres (VO2+). The spectrometer operated at the X-band (9.75 GHz) using an ER 4102ST TE102 mode resonator at a microwave power of 0.5 mW, centre magnetic field at 341 mT and sweep width of 20 mT. The samples were measured after each ageing state at room temperature, inside propylene Eppendorf tubes for which further processing of the spectra was performed in order to obtain the number of spins by comparing their double integral with standard solutions.

2.3.3 Proton nuclear magnetic resonance ( 1 H-NMR)

The determination of the proton regions was performed with a high-resolution liquid-state Bruker Avance III HD 400 MHz smart probe spectrometer. After each ageing state, recording of 32 scans for each spectrum was performed, using a dissolution of the bituminous samples in deuterated tetrachloroethane inside ASTM Type 1 Class B NMR tubes. For the processing, normalisation of the area of the specific type of protons in the range of the chemical shift over the total area was conducted [38], and the chemical distribution of methyl (MetP), methylene (MtlP), α-alkyl (AlkP), olefinic (OleP) and aromatic (AroP) protons was utilised in the following.

2.3.4 Time-of-flight secondary ion mass spectrometry (TOF-SIMS)

The normalised intensity of a variety of oxygenated ion fragments was captured at the surface of the bituminous films by a TOF-SIMS IV spectrometer (ION-TOF GmbH). The preparation protocol utilises silicon substrates where bituminous films of 1 mm were formed and maintained later in the temperature range between −50 and −80 °C inside the ion source of the spectrometer. The surface is then bombarded with 25 keV Bi3 + primary ions by the liquid metal ion gun, while the emitted secondary ions are captured by the TOF analyser, resulting in the mass spectra. Three major assignments of molecular structures can be identified for all the ageing states: (OH)x, SOx-containing ion fragments and polycyclic aromatic hydrocarbons (PAH). Representative positive and negative ions from each category (OH−, C2OH−, C4OH−), (CHSO−, C2H3SO−), and (C9H7+, C10H8+, C13H9+) respectively were further employed for the contribution of the chemical products.

2.3.5 Limitations

Despite the robustness of the chemical analyses care should be taken when comparing the indices and products between them. More specifically, variations in the extent of compounds of the same chemical family may exist taking into consideration the depth of surface information, the effect of solvent and possible precipitation of the heavy fractions, the analysis temperature and the extent of volatiles based on the chosen ageing simulation. To additionally provide the potential reader with an idea of the repeatability of the conducted measurements, since average values are used in the following, the coefficient of variation was ranging between 0–30% for the chemical analyses whereas the obtained rheological parameters were within 0–10%.

2.4 Rheological tests

2.4.1 Frequency sweeps

Two DSR devices, an Anton Paar MCR 101 and an MCR 500 were used for the rheological assessment of the bituminous binders. The former was used for the low-temperature range, − 30 to + 10 °C, with a plate-plate geometry of 4 mm diameter, whereas the latter was used for higher temperatures ranging between 0 to + 40 °C and + 30 to + 70 °C with 8 and 25 mm diameter of plates respectively. Strain levels of 0.02, 0.05 and 1% with increasing diameter were found adequate to perform strain-controlled frequency sweeps within the linear viscoelastic region (LVER). Therefore, frequency sweeps from 0.1 to 10 Hz were conducted according to EN14770 in sandwiched samples of 1.75, 2.00 and 1.00 mm thickness by increasing diameter.

Processing of the DSR raw data was performed with the rheological software RHEA (version 2.0.2) in order to construct master curves based on the Christensen–Andersen (CA) model [39]. Various advanced rheological parameters related to ageing and specifically to non-load related cracking of bitumen can be extracted by this master curve. Recent studies have shown the evolution of these meaningful rheological parameters with ageing as well as the relationships between them [27, 40,41,42]. Hence, a selection among these rheological indicators is considered of paramount importance to evaluate the performance of a bitumen, independent of the ageing state. An overview of the rheological values used in this work alongside their definition is provided in Table 2.

2.4.2 Cup and bob test

An MCR 102 from Anton Paar was selected to be used from the available DSR devices due to the relatively high torque (200 mNm) of this device compared to the previously mentioned DSRs. The fixture of cup and bob was used for the viscosity measurements in a range of shear rates 1–100 s−1 according to EN13302. As expected all the binders behave as Newtonian fluids in all the ageing states and in the whole range of tested temperatures 110–180 °C. The determination of viscosity is an important factor in the asphalt process as it has a direct effect on mixing with the rest asphalt components and eventually on the mixture’s workability and a satisfactory asphalt compaction. Especially the threshold viscosity value of 3 Pa s at 135 °C has been used to ensure the pumpability of the examined bitumen as well as a guideline to determine mixing and compaction temperatures in the field [46]. The viscosity of bitumen has been reported to increase with ageing therefore to incorporate the effect of chemistry on this parameter is considered important. The dynamic viscosity value at 135 °C (η135 °C) was used further in the statistical analysis.

2.5 Statistical methods

2.5.1 Pearson’s r and sample correlation matrix

In multivariate data analysis, the association or relationship between the different variables is key. There are different measures to express the linear relationship between two variables. Unlike the sample covariance, the Pearson’s product-moment correlation coefficient (r) is scale-invariant. That is, its value does not depend on the units or dimensions used. Therefore, the relationships between the different chemical and different rheological parameters between the ageing states were first inspected by the Pearson’s r, using the statistical software JMP Pro 16. From a mathematical point of view, Pearson’s rij between two variables Xi and Xj is defined according to Eq. 1.

where sij is the sample covariance between Xi and Xj. If 0 < < rij < 1 then a positive linear relationship holds between the two variables, while rij ~ 0 indicates no linear relationship. On the other extrema, for values − 1 < rij < < 0 the variables correlate linearly with a negative relationship. To judge additionally if the assumed correlation is strong or weak the p value is employed in sample statistics. It shows, in simple words, the probability that a difference has been generated by a random chance. A significance level is usually set (< 0.05) indicating the percentage of risk to reject a certain hypothesis, known as the null hypothesis. For p values greater than the significance level, they report that the null hypothesis is most likely to occur. For Pearson’s r and the accompanying correlation between the variables Xi and Xj the p < 0.05 witnesses that the null hypothesis (r = 0) in this case is not true, therefore gives evidence for a certain relationship. In the second phase of the analysis, the chemical and rheological variables were used to construct sample correlation matrices containing as elements the Pearson’s r between the different variables.

2.5.2 Non-parametric wilcoxon rank sum exact test

Non-parametric statistical hypothesis tests are commonly used for small samples, typically with a number of observations n < 15, and especially when assumptions about the underlying data distribution cannot be done. The Wilcoxon exact test is used to test the null hypothesis for each pair of the two levels of a variable X. It is the non-parametric version of the equivalent parametric two-sample t-test. Also in this case the p value is the key factor for rejecting or not the null hypothesis. Using a significance level of 0.05 for a two-tailed test the null hypothesis is rejected when p < 0.05 which can be interpreted as the fact that the medians of the two populations differ significantly, otherwise for p > 0.05 the null hypothesis cannot be rejected and therefore provide evidence that the medians tend to be equal. The Wilcoxon exact test was used in this work to examine together with the Pearson’s r the two pairs (RTFO and M-TFOT) of each rheological and chemical index.

2.5.3 Multivariate factor analysis

Exploratory factor analysis is a common method for re-expressing multivariate data. The main assumption in this analysis is that the observed variance in the multivariate data is attributable to a relatively small number of common factors, the so-called latent factors. Prior to this analysis some conditions should be met and scrutinized, such as the existence of one or more groups of variables that are highly correlated as witnessed by a correlation matrix. In general, the mathematical framework of this analysis is based on the idea that for p variables X = (Χ1, Χ2, …, Χp) certain correlations exist and depend on m < p common factors F = (F1, F2, … Fm) as well as on the corresponding p error terms U. Each of the p variables is linearly dependent to the m factors in the common factor analysis which in matrix notation can be written in Eq. 2.

where L is the loading matrix containing the factor loadings lij which vary between − 1 and + 1 and can be interpreted as correlations between the original variables and the factors. Of particular interest is that the squared factor loading lij2 is the percentage of variance in variable Xi explained by the factor Fj, while the sum of the different squared factor loadings for a variable Xi is known as communality. In other words, communality shows the proportion of the variation in Xi accounted by all the common factors. Additionally, in factor analysis, the given m number of factors is, initially, based on the researcher’s choice and later is verified by the cumulative percentage of the total variance explained by the selected number of factors. As a rule of thumb, the number of factors is chosen in such a way that can explain more than 70% of the total variation and has also a meaningful interpretation [27]. Simplifying the interpretation of the factors is also necessary as obtained by the factoring method i.e. principal axis, because the obtained factors are not unique. One possible simplification method is by rotating the factors i.e. by the Varimax rotation method, which is used in the statistical software JMP Pro 16.

2.5.4 Factor analysis regression

Frequently the factor analysis is not an end step but rather an intermediate step to further data analysis. One useful application of the factors is to use them as independent variables in multiple linear regression, which is called factor analysis regression. The goal is to model the linear relationship between the independent factors derived from chemistry and a response variable, in this case, a rheological value. Hence, the location of each of the original chemical variables in the reduced factor space is needed, which is alternatively called the factor scores for the latent factors. JMP Pro 16 allows exporting the factor scores which are used as independent variables in a factor analysis regression described in Eq. 3.

where Yi is the dependent rheological variable i, Fij is the independent chemical factor score j for the prediction of the dependent variable i, b0 is the y-intercept (constant term), bj are the slope coefficients for each independent chemical factor score j and ε is the residual (error term). Some assumptions such as the linearity, the independence of observations, the normality of the residuals and the homoscedasticity should also hold here for a factor analysis regression. Finally, a statistical metric to explain the degree of variation of the outcome based on the variation of the independent variables is the coefficient of determination (R2) with values close to 1 indicating a small prediction error.

3 Results and discussion

3.1 Effect of ageing protocol

The rheological behaviour of all the binders is depicted by means of master curves in Fig. 2. A master curve is a useful illustration providing an overview of the effect of the different ageing states on a broader frequency/temperature domain. Consistent with previous works this study affirms that ageing increases the complex modulus and decreases the phase angle of bitumen. This is particularly observable in the low-frequency/high-temperature domain of the master curves and the differences because of ageing become more apparent for bitumen C in a wider frequency range. Besides this, binder A, as expected based on its bitumen grade presents higher values of the complex modulus in a wider low-temperature/high-frequency domain compared to binders B and C. In general, it is believed that ageing at low temperatures, like the one used in M-TFOT, affects to a greater level the low-temperature properties compared to ageing performed at higher temperatures, like in RTFO. Moreover, high-temperature ageing changes mainly the shape parameters of a master curve. Counterbalancing these changes due to different ageing temperatures can be possibly achieved with an appropriate selection of the ageing duration.

Of particular importance is the convergence of the M-TFOT and RTFO master curves for all the binders. It has been shown that the transition point between the two rate-determining oxidation phases under the specific conditions of M-TFOT occurs around 8 days. The findings here support an association between this ageing state (8 days M-TFOT) and the standardised laboratory simulation for short-term ageing, while the binders exhibited their most extreme values after PAV ageing. The comparability of the two ageing states is further investigated using statistical analysis.

To examine the initial observation of the rheological convergence of M-TFOT and RTFO as well as the corresponding evolution of the chemical parameters, bivariate analysis was used. This analysis will allow concluding if binders that differ in terms of type follow the same evolution for their rheological and chemical changes irrespective of the ageing simulation. The two ageing states are treated as a dependent and independent variable with two sets of values (domains), namely chemical and rheological, including all three binders. The chemical parameters include all the parameters investigated and explained in Sect. 2.3, whereas the rheological parameters extracted from the master curves (Sect. 2.4.) are used as another domain. Differentiation between the binders from a chemical perspective can be mainly seen in their intensity as depicted in Fig. 3 [top], something which is particularly pronounced for the CBOR and ARI of bitumen C. Moreover, since the values differ in terms of magnitude, two bivariate plots are performed for each domain to exclude the effect of magnitude errors. Figure 3 shows these bivariate plots per domain as well as the bivariate fits that are performed. This analysis can be helpful in testing simple convergence between the two states. As can be seen, the parameters of the two states seem to fit well in a linear relationship between them. It can also be seen that with regard to the radical formation of binder C, the convergence of the two ageing states is lower than for the other two binders. The reason for this observation may be found in the different wax crystallinity of this binder between the two states, which might affect the radical formation.

To further clarify the relationship between M-TFOT and RTFO the statistics of the bivariate analysis are provided in Table 3. The number of observations is based on the average values for each chemical or rheological parameter, thus, it is much higher in reality. The parameter estimation for coefficient b of the bivariate fits presents values close to the unit which means that they correlate in a fashion y = x with the intercept a interpreted here as the error between the values for each state. This holds both for the rheological and the chemical parameters, as well as for low and high magnitude values. In addition, the Pearson’s r shows a strong positive correlation of this relationship with values close to 1. The significance of this positive correlation between the two states for both sets of parameters is further justified by the p values, which are much lower than the threshold level of 0.05. The coefficient of determination (R2 ~ 1) for the suggested fits is adequate to support the fitting choice and establish a reliable relationship between the two states. That is, not only the initial observation of the convergence of the master curves is valid but also the bivariate analysis for the rheological values confirms this claim. In parallel, the chemical parameters for the same ageing states show a significant level of convergence which implies that chemistry can follow the rheological ageing trends in bitumen for different ageing simulations and vice versa.

To further ensure that each parameter in the previous domains for all the binders is at least comparable in terms of distribution of values between the two ageing states, the Wilcoxon Rank Sum exact test was performed. The selection of this test is explained by the small number of observations for each numerical parameter. Table 4 shows that the p values for all the parameters suggest in favour of the null hypothesis (p > 0.05), therefore pointing to similar centres of location between the two levels of the grouping variable of ageing state, in this case, M-TFOT and RTFO. The lowest p values which can be interpreted here as having the highest probability to show different distribution between the two states were found for the (OH)x and SOx-containing ion fragments as well as the SOI. This test strengthens the existence of convergence between the two ageing states not only for their domains but also for the individual parameters.

Together the two statistical approaches show that similar levels of rheological and chemical parameters can be succeeded between the transition point (8 days) of the oxidation kinetics with M-TFOT and routine lab simulation of short-term ageing. It is fair enough to consider that although the ageing protocol differs i.e. RTFO incorporates airflow and rotation in contrary to M-TFOT, once the same ageing level has been reached in terms of rheological performance, the chemistry of bitumen can follow the same trend and vice-versa. Another point, worth to be highlighted here, is the fact that although the temperature difference in the two protocols differs significantly when examining more meaningful derived rheological parameters, it seems that the change in duration can well compensate for the temperature difference. In the following statistical analysis, to avoid overloading the analysis with similar values which converge to similar ageing severity both for rheology and chemistry, only the values of RTFO are utilised.

3.2 Link between chemistry and rheology

It remains to be seen if the fundamental information can be used to estimate certain rheological values and their change with ageing. Three ageing states (fresh, RTFO and PAV) for all different binder types were chosen within the framework of multivariate statistics in this study. Preliminary investigation of relationships is a requirement so that one is able to apply more sophisticated exploratory analysis i.e. factor analysis.

Hence, the parameters are first grouped in chemical and rheological. Correlation matrices are formed and shown in Tables 5 and 6. Typically a correlation matrix is a symmetric matrix including as elements the exact correlations, as realised by the Pearson’s r, between two parameters. This is particularly useful to decide on a specific threshold under which correlations are important. For consistency, only one part of the symmetric correlation matrices is given as well as only the strong correlations (r >|0.7|) are presented. It is demonstrated numerically that several correlations exist between the different chemical parameters, a fact that suggests that multivariate exploratory factor analysis can be performed for this category.

Possible explanations for the different chemical correlations can be found based on the chemical family that the compounds belong to or on their role in the ageing process. To name some of them, the SOI and CBOR have been used to distinguish the two rate-determining changes and can explain well the transition point of a fast- followed by a slow-rate oxidation phase. PAH of C13H9+, C10H8+ and C9H7+ seem to correlate well with ARI of the same chemical family. The SOx-containing fragments show also a strong correlation between them. Possible explanations behind the positive or negative correlations of specific protons with OHx-containing fragments may be found in the change of molecular associations which needs to be revealed in further studies. In general, it is believed that the individual contribution of each chemical change could have a significant effect on rheological performance although the relative increase may not be the same between the ageing states for rheology and chemistry.

Next, to minimise the number of independent variables, i.e. chemical parameters, in order to implement them in a fitting scheme of dependent ones i.e. rheological, possible relationships of the dependent variables should also be identified. Previous scholars have already reported a variety of relationships between these rheological parameters. Taking into account these well-documented relationships, the correlation matrix provided in Table 6 and the meaningful interpretation of the parameters explained previously in Table 2, the governing and most important rheological parameters were selected. Therefore, the crossover value Gc together with the R, ΔΤc and η135 oC are chosen that can capture the viscoelastic response, the relaxation, ageing-induced cracking and workability issues that occur due to ageing.

Given that the conditions to perform a factor analysis are supported by the correlation matrix of the chemical parameters, these parameters are further incorporated in the statistical software JMP Pro 16. After investigating the number of factors that can explain the total variance of the parameters, three factors proved satisfactorily to explain the total variance of the chemical parameters. The cumulative percentage of the variance explained by the three factors is 87.26% indicating that the three factors can adequately explain the total variance according to a threshold level of 70%. The rotated factor loading matrix and the communality estimates are also considered crucial to better understand and interpret the formulation of the factors which are able to reduce the number of the original chemical parameters. Table 7 clearly indicates the borders of the three factors that are highlighted for the parameters with a high factor load. More specifically, the rotated factor loadings (Varimax rotation method) in Table 7 support that Factor 1 loads heavily on C13H9+, COI, MetP, C10H8+, C4HO−, C9H7+, VO2+, C2OH−, ARI, AroP, OleP and AlkP and can account for 43.84% of the total variance. This factor explains primarily the formation and consumption of the ageing products. C13H9+, COI, MetP, C10H8+, C4HO−, C9H7+, VO2+, C2OH have a positive effect on this Factor 1 while the proton regions have a negative effect. On the other hand Factor 2 loads on SOI, MtlP, CBOR, OH− which are factors that have been shown to have an association with the transition between the fast and slow-rate phase of an oxidation scheme [21, 22]. This Factor accounts for 24.79% of the total variance while Factor 3 explains 18.64% of the total variance. Factor 3 loads heavily on the sulfoxide-related products of CHSO− and C2H3SO−. Furthermore, the total proportion of the variation per chemical variable by all the factors can be understood by the communality of each variable. The total communality estimates (Table 7) are acceptable (> 0.7) for all the parameters accounted for by the three factors. The lowest communality can be found for the vanadyl species VO2+, where a possible explanation for this observation can be the differences that have been observed for binders of different crude sources for this value; a fact that the multivariate statistics are not able to capture adequately.

Up to this point, it was possible to minimise the number of chemical parameters for all the binders and ageing states in three factors by means of factor analysis. The factor scores of this analysis were extracted and successively implemented in a factor analysis regression, where the independent factors are the factors scores for each ageing state of each bitumen and the dependent factors are the rheological parameters that have been chosen from the correlation matrix (Table 6). The coefficients of the factor analysis regression are shown in Table 8 together with the corresponding coefficient of determination. It should be noted that basic assumptions for the factor analysis regression (not shown here) have been additionally checked by inspecting the residual versus the predicted value plots.

The advantage of these linking equations is among others that the number of independent variables is relatively small and the goodness of fit is evidenced to be high enough by the R2 values for the Gc, R and ΔΤc rheological parameters. The viscosity fit is characterised as weak. The linking framework seems to differentiate the rheological properties derived in different temperature ranges, where the higher testing temperature results in a weaker fitting equation. It is also possible that the incorporation of a variety of factors in the binder’s resistance to flow may overload the fitting equation since this rheological parameter is rather simple compared to the more advanced parameters derived from the master curves and can be fitted by fewer chemical parameters i.e. carbonyls. The estimation of parameters also shows the strength of the chemical parameters per binder and its effect on rheology.

Finally, the actual and predicted (via the chemical analysis) rheological parameters are plotted in Fig. 4. The graphs highlight the convergence of the actual and predicted values for the three of the four parameters. Moreover, since correlations exist between the crossover values one is able to estimate the rest of the rheological values. The fact that the ageing effect has been taken into account in these values shows that fundamental chemistry may be the foundation stone that governs the bitumen performance. Looking back to the fundamentals of bitumen chemistry and its evolution with ageing, as well as the effect on the latent factors and the factor analysis regression will allow for the understanding of the chemical indices that deserve special attention.

4 Conclusions

This study addressed the effect of the laboratory ageing simulation on chemistry and rheology for three unmodified binders of different type and established a linking framework for the rheological performance based on fundamental chemistry parameters.

A variety of statistical methods were utilised such as bivariate analysis, correlation matrices, the Wilcoxon exact test, Factor analysis and regression for the different variables. Advanced spectroscopic techniques (FTIR, EPR, TOF–SIMS, 1H-NMR) and DSR rheological testing were employed to determine all the utilised variables. This work attempted to give answers to questions concerning the convergence of bitumen chemistry among different ageing simulations.

Exploration of two ageing simulations which showed convergence between the resulting rheological values, indicated that besides rheology, bitumen chemistry can follow similar ageing trends among different simulations. These observations allowed for the estimation of some meaningful rheological values (Gc, ΔΤc and R) by fundamental chemical indices. The statistical framework supported that advanced rheological values can be fairly accurately estimated only if a number of fundamental chemical parameters is taken into account in these fitting equations, whereas for more basic rheological properties, i.e. viscosity, the number of chemical parameters needed for an acceptable fit may be less.

Summarising, multivariate statistics have shown their potential to understand the association of the laboratory ageing changes in bitumen’s chemistry and rheology and assisted in elucidating the role of chemistry in the rheological performance of bitumen. This work may provide useful information on the specific chemical variables to focus on and control in potential bituminous advancements. Moreover, taking into account certain limits that exist for the rheological parameters of bitumen i.e. onset of cracking, one could also be able to impose certain limits for the chemical parameters based on the linking framework of this study. Based on these limits, chemical interventions on bitumen can be performed in a more comprehensive manner in the future when anti-oxidants or rejuvenators are implemented. To generalise the observations of this training dataset, in future work, a wider number of binders including commonly conventional ones of intermediate bitumen grade, modified and field aged binders should be used as a validation dataset.

Change history

23 February 2023

A Correction to this paper has been published: https://doi.org/10.1617/s11527-023-02123-x

References

Asphalt Institute Inc. and European Bitumen Association-Eurobitume (2015). The bitumen industry: A global perspective.

Redelius P, Soenen H (2015) Relation between bitumen chemistry and performance. Fuel 140:34–43. https://doi.org/10.1016/j.fuel.2014.09.044

Hajj R, Young S (2021) An analysis of theoretical and empirical relationships between two asphalt binder cracking parameters. Road Mater Pavement Des 22:S180–S196. https://doi.org/10.1080/14680629.2021.1906734

Cavalli MC, Zaumanis M, Mazza E, Partl MN, Poulikakos LD (2018) Aging effect on rheology and cracking behaviour of reclaimed binder with bio-based rejuvenators. J Clean Prod 189:88–97. https://doi.org/10.1016/j.jclepro.2018.03.305

Petersen JC, Glaser R (2011) Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater Pavement Des 12:795–819. https://doi.org/10.1080/14680629.2011.9713895

Hou X, Xiao F, Wang J, Amirkhanian S (2018) Identification of asphalt aging characterization by spectrophotometry technique. Fuel 226:230–239. https://doi.org/10.1016/j.fuel.2018.04.030

Molenaar AAA, Hagos ET, van de Ven MFC (2010) Effects of aging on the mechanical characteristics of bituminous binders in PAC. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000021

Margaritis A, Pipintakos G, Jacobs G, Hernando D, Bruynen M, Bruurs J, Van den Bergh W (2021) Evaluating the role of recycling rate and rejuvenator on the chemo-rheological properties of reclaimed polymer-modified binders. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2021.1905700

Hofko B, Alavi MZ, Grothe H, Jones D, Harvey J (2017) Repeatability and sensitivity of FTIR ATR spectral analysis methods for bituminous binders. Mater Struct 50:187. https://doi.org/10.1617/s11527-017-1059-x

The Shell Bitumen Handbook, 6th edition, ICE Publishing, 2015. https://doi.org/10.1680/tsbh.58378.

Ma L, Varveri A, Jing R, Erkens S (2021) Comprehensive review on the transport and reaction of oxygen and moisture towards coupled oxidative ageing and moisture damage of bitumen. Constr Build Mater 283:122632. https://doi.org/10.1016/j.conbuildmat.2021.122632

Mirwald J, Nura D, Eberhardsteiner L, Hofko B (2022) Impact of UV–Vis light on the oxidation of bitumen in correlation to solar spectral irradiance data. Constr Build Mater 316:125816. https://doi.org/10.1016/j.conbuildmat.2021.125816

Petersen JC (2009) A Review of the fundamentals of asphalt oxidation. Transp Res Rec J Transp Res Board. https://doi.org/10.17226/23002

Lu X, Isacsson U (2002) Effect of ageing on bitumen chemistry and rheology. Constr Build Mater 16:15–22. https://doi.org/10.1016/s0950-0618(01)00033-2

Weigel S, Stephan D (2018) Relationships between the chemistry and the physical properties of bitumen. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2017.1338189

Fischer HR, Cernescu A (2015) Relation of chemical composition to asphalt microstructure–details and properties of micro-structures in bitumen as seen by thermal and friction force microscopy and by scanning near-filed optical microscopy. Fuel. 153:628–633. https://doi.org/10.1016/j.fuel.2015.03.043

Mühlich U, Pipintakos G, Tsakalidis C (2021) Mechanism based diffusion-reaction modelling for predicting the influence of SARA composition and ageing stage on spurt completion time and diffusivity in bitumen. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120592

Yu X, Burnham NA, Tao M (2015) Surface microstructure of bitumen characterized by atomic force microscopy. Adv Colloid Interface Sci 218:17–33. https://doi.org/10.1016/j.cis.2015.01.003

Petersen J, Harnsberger P (1998) Asphalt aging: dual oxidation mechanism and its interrelationships with asphalt composition and oxidative age hardening, transp. res. Rec J Transp Res Board 1638:47–55. https://doi.org/10.3141/1638-06

Lu X, Soenen H, Sjövall P, Pipintakos G (2021) Analysis of asphaltenes and maltenes before and after long-term aging of bitumen. Fuel 304:121426. https://doi.org/10.1016/j.fuel.2021.121426

Pipintakos G, Vincent Ching HY, Soenen H, Sjövall P, Mühlich U, Van Doorslaer S, Varveri A, Van denbergh,Lu WX (2020) Experimental investigation of the oxidative ageing mechanisms in bitumen. Constr Build Mater 260:119702. https://doi.org/10.1016/j.conbuildmat.2020.119702

Pipintakos G, Soenen H, Ching HYV, Vande Velde C, Van Doorslaer S, Lemière F, Varveri A, Van den Bergh W (2021) Exploring the oxidative mechanisms of bitumen after laboratory short- and long-term ageing. Constr Build Mater 289:123182. https://doi.org/10.1016/j.conbuildmat.2021.123182

SHRP-A-370, Binder Characterization and Evaluation Volume 4: Test Methods, n.d.

Poulikakos LD, Santos S, Bueno M, Kuentzel S, Hugener M, Partl MN (2014) Influence of short and long term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr Build Mater 51:414–423. https://doi.org/10.1016/j.conbuildmat.2013.11.004

Qin Q, Schabron JF, Boysen RB, Farrar MJ (2014) Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 121:86–94. https://doi.org/10.1016/j.fuel.2013.12.040

Mirwald J, Werkovits S, Camargo I, Maschauer D, Hofko B, Grothe H (2020) Investigating bitumen long-term-ageing in the laboratory by spectroscopic analysis of the SARA fractions. Constr Build Mater 258:119577. https://doi.org/10.1016/j.conbuildmat.2020.119577

Margaritis A, Soenen H, Fransen E, Pipintakos G, Jacobs G, Blom J, Van den Bergh W (2020) Identification of ageing state clusters of reclaimed asphalt binders using principal component analysis ( PCA ) and hierarchical cluster analysis ( HCA ) based on chemo-rheological parameters. Constr Build Mater 244:118276. https://doi.org/10.1016/j.conbuildmat.2020.118276

Glover CJ, Davison RR, Domke CH, Ruan Y, Juristyarini P, Knorr DB, Jung SH (2005) Development of a new method for assessing asphalt binder durability with field validation. Texas Dept Transp 1872:1–1334

Mensching DJ, Gibson NH, Andriescu A, Rowe GM, Sias J, Assessing the Applicability of Rheological Parameters to Evaluate Modified Binders (2016).

Lesueur D, Elwardany MD, Planche JP, Christensen D, King GN (2021) Impact of the asphalt binder rheological behavior on the value of the ΔTc parameter. Constr Build Mater 293:123464. https://doi.org/10.1016/j.conbuildmat.2021.123464

EN12607–1, Bitumen and bituminous binders. Determination of the resistance to hardening under the influence of heat and air–Part 1: RTFOT method, 2007.

EN14769, Bitumen and Bituminous Binders. Accelerated Long-term Ageing Conditioning by a Pressure Ageing Vessel (PAV), 2012.

Mirwald J, Maschauer D, Hofko B, Grothe H (2020) Impact of reactive oxygen species on bitumen aging–The Viennese binder aging method. Constr Build Mater 257:119495. https://doi.org/10.1016/j.conbuildmat.2020.119495

Mirwald J, Werkovits S, Camargo I, Maschauer D, Hofko B, Grothe H (2020) Understanding bitumen ageing by investigation of its polarity fractions. Constr Build Mater 250:118809. https://doi.org/10.1016/j.conbuildmat.2020.118809

Pipintakos G, Ching HYV, Mühlich U, Soenen H, Van Doorslaer S, Sjövall P, Varveri A, Vande Velde C, Lu X (2022) Experimental validation of the dual-oxidation routes in bituminous binders BT-proceedings of the rilem international symposium on bituminous materials. In: Baaj H, Chailleux E, Tebaldi G, Sauzéat C, Mangiafico S (eds) Di Benedetto H. Springer, Cham, pp 903–909

Lu X, Redelius P (2007) Effect of bitumen wax on asphalt mixture performance. Constr Build Mater 21:1961–1970. https://doi.org/10.1016/j.conbuildmat.2006.05.048

Lamontagne J, Dumas P, Mouillet V, Kister J (2001) Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: application to road bitumens. Fuel 80:483–488. https://doi.org/10.1016/S0016-2361(00)00121-6

Rossi CO, Caputo P, De Luca G, Maiuolo L, Eskandarsefat S, Sangiorgi C (2018) 1H-NMR Spectroscopy: a possible approach to advanced bitumen characterization for industrial and paving applications. Appl Sci. https://doi.org/10.3390/app8020229

Christensen DW, Anderson DA, (1992) Interpretation of dynamic mechanical test data for paving grade asphalt cements (with discussion). J Assoc Asph Paving Technol. 61

Garcia Cucalon L, Kaseer F, Arámbula-Mercado E, Epps Martin A, Morian N, Pournoman S, Hajj E (2019) The crossover temperature: significance and application towards engineering balanced recycled binder blends. Road Mater. Pavement Des 20:1391–1412. https://doi.org/10.1080/14680629.2018.1447504

Zhang R, Sias JE, Dave EV (2020) Correlating laboratory conditioning with field aging for asphalt using rheological parameters. Transp Res Rec 2674:393–404. https://doi.org/10.1177/0361198120915894

Christensen DW, Anderson DA, Rowe GM (2017) Relaxation spectra of asphalt binders and the Christensen-Anderson rheological model. Road Mater Pavement Des 18:382–403. https://doi.org/10.1080/14680629.2016.1267448

W.S. Mogawer, T. Bennert, A. Austerman, C. Ericson, AAPT symposium: Investigating the aging mitigation capabilities of rejuvenators in high RAP mixtures using black space diagrams, binder rheology and mixture tests, in: Asph. Paving Technol. Assoc. Asph. Paving Technol. Tech. Sess., Association of Asphalt Paving Technologist, 2015: pp. 705–738.

Wang D, Falchetto AC, Riccardi C, Poulikakos L, Hofko B, Porot L, Wistuba MP, Baaj H, Mikhailenko P, Moon KH (2019) Investigation on the combined effect of aging temperatures and cooling medium on rheological properties of asphalt binder based on DSR and BBR. Road Mater Pavement Des 20:S409–S433

Anderson RM, King GN, Hanson DI, Blankenship PB, (2011) Evaluation of the relationship between asphalt binder properties and non-load related cracking. J Assoc Asph Paving Technol 80

Kennedy TW, Huber GA, Harrigan ET, Cominsky RJ, Hughes CS, Von Quintus H, Moulthrop JS (1994) Superior performing asphalt pavements (Superpave): The product of the SHRP asphalt research program. Strategic Highway Research Program, Washington

Acknowledgements

The authors gratefully acknowledge the constructive comments of Hilde Soenen (Nynas NV) which helped to improve considerably the manuscript as well as the University of Antwerp for funding and providing the lab equipment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to a retrospective Open Acess order.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pipintakos, G., Lommaert, C., Varveri, A. et al. Do chemistry and rheology follow the same laboratory ageing trends in bitumen?. Mater Struct 55, 146 (2022). https://doi.org/10.1617/s11527-022-01986-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-01986-w