Abstract

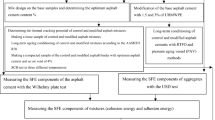

Porous asphalt concrete (PAC) is prone to fatigue cracking and moisture damage due to its open gradation and high air voids. This study presented a systematic evaluation of the role of moisture damage on the fatigue performance of PAC. The mixture was designed with a high-viscosity modified asphalt and target air void of 20%. Moisture damage was induced into the compacted specimens via different numbers of freeze–thaw (F–T) cycles, and was quantified by the parameter Dm defined as loss in the indirect tensile (IDT) strength. Fatigue characterization adopted both the single- and two-stage loading patterns and was approached by phenomenological modeling. Results indicated that the PAC strength reduced with the F–T cycle number at a decreasing rate, following an exponential decay function. The single-stage fatigue characterization yielded an S–N relationship where the intercept and slope both depended exponentially on Dm. In the two-stage characterization, the Miner’s sum declined with Dm indicating the weakening effect of the moisture conditioning. Fatigue life results from the high-low sequence seemed to suggest the presence and escalation of material sensitivity to the load level change between the two stages for F–T cycle ≥ 3. The Corten–Dolan model was adapted and applied to the two-stage loading. For both the high-low and low–high sequences, a unified expression for the parameter d in terms of Dm and the first cycle ratio α was derived. The investigation revealed that the fatigue performance of PAC became more sensitive to stress level with higher moisture damage, and exhibited higher dependence on moisture damage under larger load levels.

Similar content being viewed by others

References

Mansour TN, Putman BJ (2013) Influence of aggregate gradation on the performance properties of porous asphalt mixtures. J Mater Civ Eng 25(2):281–288

Hernandez-Saenz MA, Caro S, Arámbula-Mercado E, Martin AE (2016) Mix design, performance and maintenance of permeable friction courses (PFC) in the United States: state of the art. Constr Build Mater 111:358–367

Brattebo BO, Booth DB (2003) Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res 37(18):4369–4376

Roseen RM, Ballestero TP, Houle JJ, Briggs JF, Houle KM (2012) Water quality and hydrologic performance of a porous asphalt pavement as a storm-water treatment strategy in a cold climate. J Environ Eng 138:81–89

Mo LT, Huurman M, Wu SP, Molenaar AAA (2011) Bitumen-stone adhesive zone damage model for the meso-mechanical mixture design of reveling resistant porous asphalt concrete. Int J Fatigue 33:1490–1503

Cao W, Mohammad LN, Barghabany P, Cooper SB III, Salari S (2018) Comparison of asphalt mixtures crack resistance at intermediate temperatures using advanced test methods and theories. Transp Res Rec 2672(28):416–425

Mogawer W, Austerman A, Roque R, Underwood BS, Mohammad L, Zou J (2015) Ageing and rejuvenators: Evaluating their impact on high RAP mixtures fatigue cracking characteristics using advanced mechanistic models and testing methods. Road Mater Pavement Des 16(s2):1–28

Cao W, Mohammad LN, Elseifi M (2017) Assessing the effects of RAP, RAS, and warm-mix technologies on fatigue performance of asphalt mixtures and pavements using viscoelastic continuum damage approach. Road Mater Pavement Des 18(s4):353–371

Zhang Z, Roque R, Birgisson B, Sangpetgnam B (2001) Identification and verification of a suitable crack growth law for asphalt mixtures. J Assoc Asphalt Paving Technol 70:206–241

Cong L, Wang T, Tan L, Yuan J, Shi J (2018) Laboratory evaluation on performance of porous polyurethane mixtures and OGFC. Constr Build Mater 169:436–442

Wu JP, Herrington PR, Alabaster D (2019) Long-term durability of epoxy-modified open-graded porous asphalt wearing course. Int J Pavement Eng 20(8):920–927

Zhang J, Huang W, Zhang Y, Lv Q, Yan C (2020) Evaluating four typical fibers used for OGFC mixture modification regarding drainage, raveling, rutting and fatigue resistance. Constr Build Mater 253:119131

Xie Z, Shen J, Earnest M, Li B, Jackson M (2015) Fatigue performance evaluation of rubberized porous European mixture by simplified viscoelastic continuum damage model. Transp Res Rec 2506:90–99

Margaritis A, Pipintakos G, Varveri A, Jacobs G, Hasheminejad N, Blom J, Van den bergh W (2021) Towards an enhanced fatigue evaluation of bituminous mortars. Constr Build Mater 275:121578

Hospodka M, Hofko B, Blab R (2018) Introducing a new specimen shape to assess the fatigue performance of asphalt mastic by dynamic shear rheometer testing. Mater Struct 51:46

Kringos N, Scarpas A (2005) Raveling of asphaltic mixes due to water damage: computational identification of controlling parameters. Transp Res Rec 1929:79–87

Xu H, Chen F, Yao X, Tan Y (2018) Micro-scale moisture distribution and hydrologically active pores in partially saturated asphalt mixtures by X-ray computed tomography. Constr Build Mater 160:653–667

Nobakht M, Zhang D, Sakhaeifar MS, Lytton RL (2020) Characterization of the adhesive and cohesive moisture damage for asphalt concrete. Constr Build Mater 247:118616

Dan H-C, He L-H, Zhao L-H (2020) Experimental investigation on the resilient response of unbound graded aggregate materials by using large-scale dynamic triaxial tests. Road Mater Pavement Des 21(2):434–451

Khattak MJ, Kyatham V (2008) Viscoelastic behavior of hydrated lime-modified asphalt matrix and hot-mix asphalt under moisture damage conditions. Transp Res Rec 2057:64–74

Kim Y-R, Little DN, Lytton RL (2004) Effect of moisture damage on material properties and fatigue resistance of asphalt mixtures. Transp Res Rec 1891:48–54

Sebaaly PE, Hajj EY, Sathanathan T, Shivakolunthar S (2017) A comprehensive evaluation of moisture damage of asphalt concrete mixtures. Int J Pavement Eng 18(2):169–182

Partl MN, Pasquini E, Canestrari F, Virgili A (2010) Analysis of water and thermal sensitivity of open graded asphalt rubber mixtures. Constr Build Mater 24:283–291

Association of Japan Highway (1996) Guide for porous asphalt pavement. Maruzen Corporation, Tokyo

Ameri M, Esfahani MA (2008) Evaluation and performance of hydrated lime and limestone powder in porous asphalt. Road Mater Pavement Des 9(4):651–664

Kandhal P (2002) Design, construction, and maintenance of open-graded asphalt friction courses, Information Series 115. National Asphalt Pavement Association, Lanham, MD

American Society for Testing and Materials (2013) Standard practice for open-graded friction course (OGFC) mix design. ASTM D7064, ASTM International, West Conshohocken, PA

Alvarez AE, Epps-Martin A, Estakhri C, Izzo R (2010) Evaluation of durability tests for permeable friction course mixtures. Int J Pavement Eng 11(1):49–60

Liu K, Deng L, Jang K (2017) Study on extreme low temperature climatic zoning of high-grade highway with asphalt pavement in South China. Highway Eng 42(6):206–212

Ministry of Transport of the People's Republic of China (2011) Standard test methods of bitumen and bituminous mixtures for highway engineering. JTG E20–2011, China Communications Press, Beijing, China

You L, You Z, Dai Q, Guo S, Wang J, Schultz M (2018) Characteristics of water-foamed asphalt mixture under multiple freeze-thaw cycles: laboratory evaluation. J Mater Civ Eng 30(11):04018270

Tarefder R, Faisal H, Barlas G (2018) Freeze-thaw effects on fatigue life of hot mix asphalt and creep stiffness of asphalt binder. Cold Reg Sci Technol 153:197–204

Dan H-C, Bai G-W, Zhu Z (2021) Application of deep learning-based image recognition technology to asphalt–aggregate mixtures: methodology. Constr Build Mater 297:123770

Miner MA (1945) Cumulative damage in fatigue. J Appl Mech 67:A159–A164

Skorupa M (1999) Load interaction effects during fatigue crack growth under variable amplitude loading—a literature review. Part II: qualitative interpretation. Fatigue Fract Eng Mater Struct 22:905–926

Zuo F-J, Huang H-Z, Zhu S-P, Lv Z, Gao H (2015) Fatigue life prediction under variable amplitude loading using a non-linear damage accumulation model. Int J Damage Mech 24(5):767–784

Liu Q, Gao Y, Li Y, Xue Q (2020) Fatigue life prediction based on a novel improved version of the Corten–Dolan model considering load interaction effect. Eng Struct 221:111036

Corten HT, Dolan TJ (1956) Cumulative fatigue damage. In Proceedings of the international conference on fatigue of metals, Institution of Mechanical Engineering and American Society of Mechanical Engineers, London, pp 235–246

Gao HY, Huang H-Z, Lv Z, Zuo F-J, Wang H-K (2015) An improved Corten–Dolan’s model based on damage and stress state effects. J Mech Sci Technol 29(8):3215–3223

Chen DG (1996) The method of determining the exponent d in the Corten–Dolan’s fatigue damage formular. J Mech Strength 18(1):21–24

Zhu S-P, Huang H-Z, Liu Y, He L-P, Liao Q (2012) A practical method for determining the Corten–Dolan exponent and its application to fatigue life prediction. Int J Turbo Jet Engines 29(2):79–87

Funding

The authors would like to acknowledge the financial supports from the Natural Science Foundation of Hunan Province (Grant No. 2020JJ4702), Guizhou Transportation Science and Technology Foundation of China (Grant No. 2019–122-006), and Jiangxi Transportation Science and Technology Foundation of China (Grant No. 2020H0028).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dan, HC., Ling, C., Cao, W. et al. Fatigue behavior and phenomenological modeling of porous asphalt concrete under freeze–thaw cycling. Mater Struct 54, 235 (2021). https://doi.org/10.1617/s11527-021-01829-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01829-0