Abstract

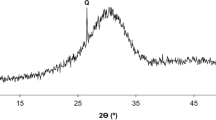

The aim of this work was to benchmark several binders by testing their capacity to resist external sulfate attack (ESA) under similar experimental conditions. Concrete samples were fabricated from seven different binders: two Portland cements, one blast furnace slag Portland cement, one super sulfated ground granulated blast furnace slag cement, one sodium carbonate alkali-activated slag cement, one metakaolin geopolymer and one calcium sulfoaluminate-belite cement. Mechanical strength measurements were used to characterize the concretes in the hardened state. Resistance to ESA was studied by measuring the longitudinal expansion of concretes submerged in a sulfate solution. In order to better understand the behavior of the binders in ESA, this study was completed by microstructural and mineralogical analyses carried out before and after attack by using Scanning Electron Microscopy with Energy Dispersive Spectroscopy (SEM/EDS), X-ray diffraction and thermodynamic calculations. It was found that ordinary Portland cement had high expansions (> 0.1%) due to the formation of excess ettringite caused by the reaction between aluminates and sulfates. Portland cement without C3A presented lower expansions but gypsum was found to be responsible for cracking at later ages. Alternative binders had low expansions, in the range of 0.01–0.03%, explained by the absence of C3A and portlandite, in addition to the formation of ettringite during hydration (case of ettringite binders) and the absence of calcium (case of the geopolymer-based metakaolin).

Similar content being viewed by others

Notes

Characteristic strength, i.e., value of strength below which 5% of the population of all possible strength determinations of the volume of concrete under consideration are expected to fall [EN 206]; the first value is for cylinders, the second for cubes.

References

Müllauer W, Beddoe RE, Heinz D (2013) Sulfate attack expansion mechanisms. Cem Concr Res 52:208–215. https://doi.org/10.1016/j.cemconres.2013.07.005

Komljenović M, Džunuzović N, Nikolić V (2018) Resistance to external sulfate attack - comparison of two alkali-activated binders. MATEC Web of Conf 163:6001. https://doi.org/10.1051/matecconf/201816306001

Bescher E, Rice EK, Ramseyer C, Roswurm S (2016) Sulfate resistance of calcium sulphoaluminate cement. J Struct Integr Maint 1:131–139. https://doi.org/10.1080/24705314.2016.1211235

Ye H, Chen Z, Huang L (2019) Mechanism of sulfate attack on alkali-activated slag: the role of activator composition. Cem Concr Res 125:105868. https://doi.org/10.1016/j.cemconres.2019.105868

Ismail I, Bernal SA, Provis JL, Hamdan S, Van Deventer JSJ (2013) Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater Struct/Mater et Constr 46:361–373. https://doi.org/10.1617/s11527-012-9906-2

Santhanam M, Cohen MD, Olek J (2002) Mechanism of sulfate attack: a fresh look - Part 1 summary of experimental results. Cem Concr Res 32:915–921. https://doi.org/10.1016/S0008-8846(02)00724-X

Schmidt T, Lothenbach B, Romer M, Neuenschwander J, Scrivener K (2009) Physical and microstructural aspects of sulfate attack on ordinary and limestone blended Portland cements. Cem Concr Res 39:1111–1121. https://doi.org/10.1016/j.cemconres.2009.08.005

Tian B, Cohen MD (2000) Does gypsum formation during sulfate attack on concrete lead to expansion? Cem Concr Res 30:117–123. https://doi.org/10.1016/S0008-8846(99)00211-2

Idiart AE, López CM, Carol I (2011) Chemo-mechanical analysis of concrete cracking and degradation due to external sulfate attack: a meso-scale model. Cement Concr Compos 33:411–423. https://doi.org/10.1016/j.cemconcomp.2010.12.001

Scherer GW (2004) Stress from crystallization of salt. Cem Concr Res 34:1613–1624. https://doi.org/10.1016/j.cemconres.2003.12.034

Scherer GW (1999) Crystallization in pores. Cem Concr Res 29:1347–1358. https://doi.org/10.1016/S0008-8846(99)00002-2

Mehta PK (1973) Mechanism of expansion associated with ettringite formation. Cem Concr Res 3:1–6. https://doi.org/10.1016/0008-8846(73)90056-2

Gollop RS, Taylor HFW (1995) Microstructural and microanalytical studies of sulfate attack III sulfate-resisting portland cement: reactions with sodium and magnesium sulfate solutions. Cem Concr Res 25:1581–1590. https://doi.org/10.1016/0008-8846(95)00151-2

Heller L, Ben-Yair M (2007) Effect of sulphate solutions on normal and sulphate-resisting portland cement. J Appl Chem 14:20–30. https://doi.org/10.1002/jctb.5010140103

Ghosh SN (1983) ed., Advances in cement technology, 1st ed. https://doi.org/10.1016/c2013-0-06042-2

Trägårdh J, Bellmann F (2001) Sulphate attack, in: structural survey, pp. 89–118. https://doi.org/10.1108/ss.2001.11019bab.003

Ouyang C, Nanni A, Chang WF (1988) Internal and external sources of sulfate ions in portland cement mortar: two types of chemical attack. Cem Concr Res 18:699–709. https://doi.org/10.1016/0008-8846(88)90092-0

Džunuzović N, Komljenović M, Nikolić V, Ivanović T (2017) External sulfate attack on alkali-activated fly ash-blast furnace slag composite. Constr Build Mater 157:737–747. https://doi.org/10.1016/j.conbuildmat.2017.09.159

Duan P, Yan C, Zhou W (2016) Influence of partial replacement of fly ash by metakaolin on mechanical properties and microstructure of fly ash geopolymer paste exposed to sulfate attack. Ceram Int 42:3504–3517. https://doi.org/10.1016/j.ceramint.2015.10.154

Karakoç MB, Türkmen I, Maraş MM, Kantarci F, Demirbota R (2016) Sulfate resistance of ferrochrome slag based geopolymer concrete. Ceram Int 42:1254–1260. https://doi.org/10.1016/j.ceramint.2015.09.058

Elyamany HE, Abd Elmoaty AEM, Elshaboury AM (2018) Magnesium sulfate resistance of geopolymer mortar. Constr Build Mater 184:111–127. https://doi.org/10.1016/j.conbuildmat.2018.06.212

Sata V, Sathonsaowaphak A, Chindaprasirt P (2012) Resistance of lignite bottom ash geopolymer mortar to sulfate and sulfuric acid attack. Cement Concr Compos 34:700–708. https://doi.org/10.1016/j.cemconcomp.2012.01.010

Komljenović M, Baščarević Z, Marjanović N, Nikolić V (2013) External sulfate attack on alkali-activated slag. Constr Build Mater 49:31–39. https://doi.org/10.1016/j.conbuildmat.2013.08.013

Bakharev T, Sanjayan JG, Cheng YB (2002) Sulfate attack on alkali-activated slag concrete. Cem Concr Res 32:211–216. https://doi.org/10.1016/S0008-8846(01)00659-7

Allahverdi A, Hashemi H, Mahinroosta M (2020) Resistance of alkali-activated slag cement against sodium sulfate. Iran J Mater Sci Eng. https://doi.org/10.22068/ijmse.17.1.23

Chindaprasirt P, Rattanasak U, Taebuanhuad S (2013) Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater Struct 46:375–381. https://doi.org/10.1617/s11527-012-9907-1

Alcamand HA, Borges PHR, Silva FA, Trindade ACC (2018) The effect of matrix composition and calcium content on the sulfate durability of metakaolin and metakaolin/slag alkali-activated mortars. Ceram Int 44:5037–5044. https://doi.org/10.1016/j.ceramint.2017.12.102

Chen IA, Hargis CW, Juenger MCG (2012) Understanding expansion in calcium sulfoaluminate-belite cements. Cem Concr Res 42:51–60. https://doi.org/10.1016/j.cemconres.2011.07.010

Hargis CW, Lothenbach B, Müller CJ, Winnefeld F (2019) Further insights into calcium sulfoaluminate cement expansion. Adv Cem Res 31:160–177. https://doi.org/10.1680/jadcr.18.00124

Ogawa K, Roy DM (1982) C4A3S̄ hydration, ettringite formation, and its expansion mechanism: III. Effect of CaO, NaOH and NaCl; conclusions. Cem Concr Res 12:247–256. https://doi.org/10.1016/0008-8846(82)90011-4

Beretka J, Marroccoli M, Sherman N, Valenti GL (1996) The influence of C4A3S̄ content and WS ratio on the performance of calcium sulfoaluminate-based cements. Cem Concr Res 26:1673–1681. https://doi.org/10.1016/S0008-8846(96)00164-0

Kurdowski W, Thiel A (1981) On the role of free calcium oxide in expansive cements. Cem Concr Res 11:29–40. https://doi.org/10.1016/0008-8846(81)90006-5

Glasser FP, Zhang L (2001) High-performance cement matrices based on calcium sulfoaluminate-belite compositions. Cem Concr Res 31:1881–1886. https://doi.org/10.1016/S0008-8846(01)00649-4

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cem Concr Res 41:1232–1243. https://doi.org/10.1016/j.cemconres.2010.11.012

Grounds T, Nowell DV, Wilburn FW (2003) Resistance of supersulfated cement to strong sulfate solutions. J Therm Anal Calorim 72:181–190. https://doi.org/10.1023/A:1023928021602

Niu Q, Zhang R (2015) Effect of supersulphated cement on sulfate attack of cement mortar, In: Proceedings of the 3rd international conference on advances in energy and environmental science 2015, Atlantis Press, Paris, France. https://doi.org/10.2991/icaees-15.2015.269

Bernardo G, Telesca A, Valenti GL (2006) A porosimetric study of calcium sulfoaluminate cement pastes cured at early ages. Cem Concr Res 36:1042–1047. https://doi.org/10.1016/j.cemconres.2006.02.014

Ndiaye K, Cyr M, Ginestet S (2020) Development of a cementitious material for thermal energy storage at low temperature. Constr Build Mater 242:118130. https://doi.org/10.1016/j.conbuildmat.2020.118130

Hewlett PC, Liska M (2019) eds., Lea’s chemistry of cement and concrete, Elsevier. https://doi.org/10.1016/C2013-0-19325-7

Trentin PO, Magro IC, Souza LRMN, Homrich JTO, Angulski da Luz C, Bonini JS (2019) Comparativo entre cimento Portland e cimento supersulfatado submetidos ao ataque por sulfato de sódio: resistência mecânica e variação dimensional. Revista Técnico-Científica. https://doi.org/10.4322/2526-7248.050

Diaz Caselles L (2020) Stabilisation des sulfates et du molybdène par des liants alternatifs, 2020. http://www.theses.fr/2020TOU30255/document

Chen W, Brouwers HJH (2007) The hydration of slag, part 2: reaction models for blended cement. J Mater Sci 42:444–464. https://doi.org/10.1007/s10853-006-0874-1

Kolani B, Buffo-Lacarrière L, Sellier A, Escadeillas G, Boutillon L, Linger L (2012) Hydration of slag-blended cements. Cement Concr Compos 34:1009–1018. https://doi.org/10.1016/j.cemconcomp.2012.05.007

Winnefeld F, Lothenbach B (2010) Hydration of calcium sulfoaluminate cements - experimental findings and thermodynamic modelling. Cem Concr Res 40:1239–1247. https://doi.org/10.1016/j.cemconres.2009.08.014

Pouhet R, Cyr M (2016) Formulation and performance of flash metakaolin geopolymer concretes. Constr Build Mater 120:150–160. https://doi.org/10.1016/j.conbuildmat.2016.05.061

Hardjito D, Wallah SE, Sumajouw DMJ, Rangan BV (2004) Factors influencing the compressive strength of fly ash-based geopolymer concrete. Civil Eng Dim 6:88–93. https://doi.org/10.9744/ced.6.2.pp.%2088-93

Lothenbach B, Le Saout G, Ben Haha M, Figi R, Wieland E (2012) Hydration of a low-alkali CEM III/B-SiO2 cement (LAC). Cem Concr Res 42:410–423. https://doi.org/10.1016/j.cemconres.2011.11.008

Winnefeld F, Gluth GJG, Bernal SA, Bignozzi MC, Carabba L, Chithiraputhiran S, Dehghan A, Dolenec S, Dombrowski-Daube K, Dubey A, Ducman V, Jin Y, Peterson K, Stephan D, Provis JL (2020) RILEM TC 247-DTA round robin test: sulfate resistance, alkali-silica reaction and freeze–thaw resistance of alkali-activated concretes. Mater Struct 53:140. https://doi.org/10.1617/s11527-020-01562-0

Leemann A, Loser R (2012) Accelerated sulfate resistance test for concrete - chemical and microstructural aspects, In: 2nd International conference on microstructural-related durability of cementitious composites, pp 1–12

Kaufmann J, Loser R, Winnefeld F, Leemann A (2021) Sulfate resistance and phase composition of shotcrete. Tunn Undergr Space Technol 109:103760. https://doi.org/10.1016/j.tust.2020.103760

Cyr M, Rivard P, Labrecque F, Daidié A (2008) High-pressure device for fluid extraction from porous materials: application to cement-based materials. J Am Ceram Soc 91:2653–2658. https://doi.org/10.1111/j.1551-2916.2008.02525.x

Parkhurst DL, Appelo CAJ (2013) PHREEQC (Version 3)-A computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Model Tech B 6:99–4259

Helgeson HC (1969) Thermodynamics of hydrothermal systems at elevated temperatures and pressures. Am J Sci 267:729–804. https://doi.org/10.2475/ajs.267.7.729

Blanc P, Lassin A, Piantone P, Azaroual M, Jacquemet N, Fabbri A, Gaucher EC (2012) Thermoddem: a geochemical database focused on low temperature water/rock interactions and waste materials. Appl Geochem 27:2107–2116. https://doi.org/10.1016/j.apgeochem.2012.06.002

Winnefeld F, Martin LHJ, Müller CJ, Lothenbach B (2017) Using gypsum to control hydration kinetics of CSA cements. Constr Build Mater 155:154–163. https://doi.org/10.1016/j.conbuildmat.2017.07.217

Berrio A, Rodriguez C, Tobón JI (2018) Effect of Al2O3/SiO2 ratio on ye’elimite production on CSA cement. Constr Build Mater 168:512–521. https://doi.org/10.1016/j.conbuildmat.2018.02.153

García-Maté M, Santacruz I, De La Torre ÁG, León-Reina L, Aranda MAG (2012) Rheological and hydration characterization of calcium sulfoaluminate cement pastes. Cement Concr Compos 34:684–691. https://doi.org/10.1016/j.cemconcomp.2012.01.008

Baux C, Phelipot-Mardelé A, Lanos C, Pierre A (2014) Mechanical performances of super sulfated cements. Key Eng Mater 617:32–35

Kovtun M, Kearsley EP, Shekhovtsova J (2015) Chemical acceleration of a neutral granulated blast-furnace slag activated by sodium carbonate. Cem Concr Res 72:1–9. https://doi.org/10.1016/j.cemconres.2015.02.014

Zhang H, Luo S (2007) Modeling the leaching behavior of simulated HLW-glass using PHREEQC. Nucl Sci Tech/Hewuli 18:150–153. https://doi.org/10.1016/S1001-8042(07)60037-2

Benavente D, Brimblecombe P, Grossi CM (2015) Thermodynamic calculations for the salt crystallisation damage in porous built heritage using PHREEQC. Environ Earth Sci 74:2297–2313. https://doi.org/10.1007/s12665-015-4221-1

Stuyfzand PJ (1989) An accurate, relatively simple calculation of the saturation index of calcite for fresh to salt water. J Hydrol 105:95–107. https://doi.org/10.1016/0022-1694(89)90098-X

Balendran RV, Pang HW, Wen HX (1998) Use of scanning electron microscopy in concrete studies. Struct Surv 16:146–153. https://doi.org/10.1108/02630809810232718

Scrivener K, Snellings R, Lothenbach B (eds) (2015) A practical guide to microstructural analysis of cementitious materials. Crc Press

Feng P, Garboczi EJ, Miao C, Bullard JW (2015) Microstructural origins of cement paste degradation by external sulfate attack. Constr Build Mater 96:391–403. https://doi.org/10.1016/j.conbuildmat.2015.07.186

Whittaker M, Black L (2015) Current knowledge of external sulfate attack. Adv Cem Res 27:532–545. https://doi.org/10.1680/adcr.14.00089

Wild S, Kinuthia JM, Jones GI, Higgins DD (1999) Suppression of swelling associated with ettringite formation in lime stabilized sulphate bearing clay soils by partial substitution of lime with ground granulated blastfurnace slag. Eng Geol 51:257–277. https://doi.org/10.1016/S0013-7952(98)00069-6

Wild S, Tasong WA (1999) Influence of ground granulated blastfurnace slag on the sulphate resistance of lime-stabilized kaolinite. Mag Concr Res 51:247–254. https://doi.org/10.1680/macr.1999.51.4.247

Diaz Caselles L, Hot J, Roosz C, Cyr M (2020) Stabilization of soils containing sulfates by using alternative hydraulic binders. Appl Geochem 113:104494. https://doi.org/10.1016/j.apgeochem.2019.104494

Ogawa K, Roy DM (1982) C4A3S hydration, ettringite formation, and its expansion mechanism: II microstructural observation of expansion. Cem Concr Res 12:101–109. https://doi.org/10.1016/0008-8846(82)90104-1

Yu C, Sun W, Scrivener K (2015) Degradation mechanism of slag blended mortars immersed in sodium sulfate solution. Cem Concr Res 72:37–47. https://doi.org/10.1016/j.cemconres.2015.02.015

Cerulli T, Pistolesi C, Maltese C, Salvioni D (2003) Durability of traditional plasters with respect to blast furnace slag-based plaster. Cem Concr Res 33:1375–1383. https://doi.org/10.1016/S0008-8846(03)00072-3

Kharchenco I, Alekseev V (2019) Effect of ettringite morphology on the properties of expanding cement systems. E3S Web Conf 110:01037. https://doi.org/10.1051/e3sconf/201911001037

Yu J, Qian J, Tang J, Ji Z, Fan Y (2019) Effect of ettringite seed crystals on the properties of calcium sulphoaluminate cement. Constr Build Mater 207:249–257. https://doi.org/10.1016/j.conbuildmat.2019.02.130

Escadeillas G, Hornain H (2008) La durabilité des bétons vis-a-vis des environnements chimiquement agressifs. In: La Durabilité Des Bétons, pp. 613–705

Tosun K, Baradan B (2010) Effect of ettringite morphology on DEF-related expansion. Cem Concr Compos 32:271–280. https://doi.org/10.1016/j.cemconcomp.2010.01.002

Pajares I, Martínez-Ramírez S, Blanco-Varela M (2003) Evolution of ettringite in presence of carbonate, and silicate ions. Cem Concr Compos 25: 861–865. https://doi.org/10.1016/S0958-9465(03)00113-6

Ben Haha M, Lothenbach B, Le Saout G, Winnefeld F (2012) Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag — Part II: effect of Al2O3. Cem Concr Res 42:74–83. https://doi.org/10.1016/j.cemconres.2011.08.005

Funding

This work was supported by the French Ministry of Higher Education and Research and the National Association for Research and Technology (ANRT) in the framework of French Cifre fellowships.

Author information

Authors and Affiliations

Contributions

LDC Investigation, Methodology, Writing—Original Draft, Project administration. JH Supervision, Writing—review and editing. FC Conceptualization, Validation. MC Conceptualization, Writing—review and editing, Supervision, Funding acquisition, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Diaz Caselles, L., Hot, J., Cassagnabère, F. et al. External sulfate attack: comparison of several alternative binders. Mater Struct 54, 216 (2021). https://doi.org/10.1617/s11527-021-01813-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01813-8