Abstract

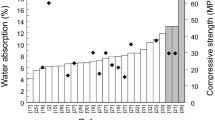

The quality control of aggregates for concrete involves determining their water absorption and apparent density, indicators of the material’s porosity. The standard methods were developed for natural aggregates and are less appropriate for construction and demolition waste recycled aggregates (RAs), which have greater porosity and variability. This paper presents a rapid and accurate method to measure water absorption of RAs, combining 0.5 h vacuum saturation with ~2 h microwave oven drying kinetics. The new method anticipates the results by 43.5 h in comparison of standard ASTM C127, making it appealing for quality control operations. Statistical analysis shows new method gives statistically equivalent results for porous recycled aggregates but it over estimates low porosity natural aggregates. Results of the proposed method are different less than 0.5 % of those obtained by standard methods when testing three RAs with absorptions varying between 5 and 19 %. Operator did not influence the results of the new method. Details of the new experimental procedure and equipment developed are given. Suggestions for further improvement of the new method presented.

Similar content being viewed by others

References

Tam CM, Tam VWY, Wang K (2007) Ways to facilitate the use of recycled aggregate concrete. Proc ICE Waste Resour Manag 160:125–129. doi:10.1680/warm.2007.160.3.125

Wu Z, Yu ATW, Shen L, Liu G (2014) Quantifying construction and demolition waste: an analytical review. Waste Manag 34:1683–1692. doi:10.1016/j.wasman.2014.05.010

Agrela F, Sánchez de Juan M, Ayuso J et al (2011) Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr Build Mater 25:3950–3955. doi:10.1016/j.conbuildmat.2011.04.027

Angulo SC, Carrijo PM, Figueiredo AD et al (2010) On the classification of mixed construction and demolition waste aggregate by porosity and its impact on the mechanical performance of concrete. Mater Struct 43:519–528. doi:10.1617/s11527-009-9508-9

Behera M, Bhattacharyya SK, Minocha AK et al (2014) Recycled aggregate from C&D waste and its use in concrete—a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516. doi:10.1016/j.conbuildmat.2014.07.003

Vázquez E (2013) Construction and demolition waste recycling in a broader environmental perspective. In: Vázquez E (ed) Progress of recycling in the built environment. Springer, Dordrecht, pp 5–35

Soutsos MN, Tang K, Millard SG (2011) Concrete building blocks made with recycled demolition aggregate. Constr Build Mater 25:726–735. doi:10.1016/j.conbuildmat.2010.07.014

Edwards JP, Wint J, Ghazireh N, Cearns P (2007) WAS005-002: Final Report - Recycled and stabilised materials in trench reinstatement. Waste & Resources Action Programme, 33 p

Arulrajah A, Piratheepan J, Disfani M, Bo M (2013) Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J Mater Civ Eng 25:1077–1088. doi:10.1061/(ASCE)MT.1943-5533.0000652

de Juan MS, Gutiérrez PA (2009) Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr Build Mater 23:872–877. doi:10.1016/j.conbuildmat.2008.04.012

Medina C, Sánchez de Rojas MI, Frías M (2013) Properties of recycled ceramic aggregate concretes: water resistance. Cem Concr Compos 40:21–29. doi:10.1016/j.cemconcomp.2013.04.005

Pacheco-Torgal F, Jalali S (2010) Reusing ceramic wastes in concrete. Constr Build Mater 24:832–838. doi:10.1016/j.conbuildmat.2009.10.023

Belin P, Habert G, Thiery M, Roussel N (2014) Cement paste content and water absorption of recycled concrete coarse aggregates. Mater Struct. doi:10.1617/s11527-013-0128-z

Butler L, West JS, Tighe SL (2011) The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem Concr Res 41:1037–1049. doi:10.1016/j.cemconres.2011.06.004

Hoffmann C, Schubert S, Leemann A, Motavalli M (2012) Recycled concrete and mixed rubble as aggregates: influence of variations in composition on the concrete properties and their use as structural material. Constr Build Mater 35:701–709. doi:10.1016/j.conbuildmat.2011.10.007

Quattrone M, Angulo SC, Damineli BL, John VM (2014) Influence of recycled aggregate in binder intensity of concretes. In: Concrete Innovation Conference - CIC2014, At Oslo, Norway

Duan ZH, Poon CS (2014) Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater Des 58:19–29. doi:10.1016/j.matdes.2014.01.044

Kou S-C, Poon C-S, Wan H-W (2012) Properties of concrete prepared with low-grade recycled aggregates. Constr Build Mater 36:881–889. doi:10.1016/j.conbuildmat.2012.06.060

Hendriks CF (2004) A new vision on the building cycle. Uitgeverij Æneas BV

Ogawa H, Nawa T (2012) Improving the quality of recycled fine aggregate by selective removal of brittle defects. J Adv Concr Technol 10:395–410. doi:10.3151/jact.10.395

Alaejos P, de Juan MS, Rueda J et al (2013) Quality Assurance of recycled aggregates. In: Vázquez E (ed) Progress of recycling in the built environment. Springer, Dordrecht, pp 229–273

Recommendation of RILEM (1994) Specifications for concrete with recycled aggregates. Mater Struct 27:557–559. doi:10.1007/BF02473217

C09 Committee (2012) ASTM C127:2012 - Test method for density, relative density (specific gravity), and absorption of coarse aggregate. ASTM International

ABNT/CB-018 (2009) ABNT NBR NM 53:2009 Coarse aggregate—determination of the bulk specific gravity, apparent specific gravity and water absorption

CEN TC B/502/6 (2013) EN 1097-6:2013 Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption

Djerbi Tegguer A (2012) Determining the water absorption of recycled aggregates utilizing hydrostatic weighing approach. Constr Build Mater 27:112–116. doi:10.1016/j.conbuildmat.2011.08.018

Safiuddin M, Mahmud HB, Jumaat MZ (2011) Efficacy of ASTM saturation techniques for measuring the water absorption of concrete. Arab J Sci Eng 36:761–768. doi:10.1007/s13369-011-0080-6

Schouenborg B, Aurstad J, Pétursson P (2004) Test methods adapted to alternative aggregates. In: Vázquez E, Hendriks ChF, Janssen GMT (eds) International RILEM conference on the use of recycled materials in buildings and structures, Barcelona, p 1154

Tam VWY, Gao XF, Tam CM, Chan CH (2008) New approach in measuring water absorption of recycled aggregates. Constr Build Mater 22:364–369. doi:10.1016/j.conbuildmat.2006.08.009

Zaharieva R, Buyle-Bodin F, Skoczylas F, Wirquin E (2003) Assessment of the surface permeation properties of recycled aggregate concrete. Cem Concr Compos 25:223–232. doi:10.1016/S0958-9465(02)00010-0

C09 Committee (2007) ASTM C 128 test method for density, relative density (specific gravity), and absorption of fine aggregate. ASTM International, West Conshohocken

You Z, Mills-Beale J, Williams RC, Dai Q (2009) Development of new test procedures for determining the specific gravity and absorption of fine and coarse aggregates. Michigan Department of Transportation Construction Paving Unit

Mills-Beale J, You Z, Williams RC, Dai Q (2009) Determining the specific gravities of coarse aggregates utilizing vacuum saturation approach. Constr Build Mater 23:1316–1322. doi:10.1016/j.conbuildmat.2008.07.025

D04 Committee (2009) ASTM D7370—test method for determination of relative density and absorption of fine, coarse and blended aggregate using combined vacuum saturation and rapid submersion. ASTM International, West Conshohocken

Kropp J (2005) Bestimmung der Kernfeuchte wassergesättigter: Bauschuttrezyklate anhand des Trocknungsverhaltens. In: Amtliche Mater. Bremen, Germany, 12 p

Mechling J-M, Lecomte A, Merriaux K (2003) Mesure de l’absorption d’eau des additions minérales des bétons par évaporométrie. Mater Struct 36:32–39. doi:10.1007/BF02481568

Miller A, Spragg R, Antico F et al (2014) Determining the moisture content of pre-wetted lightweight aggregate: assessing the variability of the paper towel and centrifuge methods. Int. Conf. Durab. Concr, Struct

Miller AE, Barrett TJ, Zander AR, Weiss WJ (2014) Using a centrifuge to determine moisture properties of lightweight fine aggregate for use in internal curing. Adv Civ Eng Mater 3:20130111. doi:10.1520/ACEM20130111

Kandhal P, Mallick R, Huner M (2000) Measuring bulk-specific gravity of fine aggregates: development of new test method. Transp Res Rec J Transp Res Board 1721:81–90. doi:10.3141/1721-10

Gentilini P, Yazoghli-Marzouk O, Delmotte V, Descantes Y (2015) Determination of the water content of fillerised fine aggregates in the saturated surface dry state. Constr Build Mater 98:662–670. doi:10.1016/j.conbuildmat.2015.08.131

C09 Committee (2013) ASTM C566—test method for total evaporable moisture content of aggregate by drying. ASTM International, West Conshohocken

MAIN ROADS Western Australia (2012) TEST METHOD WA 212.2–2012 Determination of the moisture content of aggregate - Microwave Oven Drying Method (Subsidiary Method)

McCabe W, Smith J, Harriott P (2004) Unit operations of chemical engineering, 7th edn. McGraw-Hill Science/Engineering/Math, Boston

Moss AAH, Nonhebel G (1971) Drying of solids in the chemical industry. Butterworth & Co Publishers Ltd, London

Ceaglske NH, Hougen OA (1937) Drying granular solids. Ind Eng Chem 29:805–813. doi:10.1021/ie50331a017

Box GEP (2009) Statistics for experimenters: design, innovation, and discovery, second edition + JMP version 6 software student edition, set. Wiley, New York

World Health Organization (2014) Electromagnetic fields & public health: Microwave ovens. In: WHO. http://www.who.int/peh-emf/publications/facts/info_microwaves/en/. Accessed 18 Sep 2014

Alarcon-Ruiz L, Platret G, Massieu E, Ehrlacher A (2005) The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem Concr Res 35:609–613. doi:10.1016/j.cemconres.2004.06.015

Arce GR (2005) Median and weighted median smoothers. In: Arce GR (ed) Nonlinear signal process. Wiley, Hoboken, pp 80–138

Webb PA (2001) Volume and density determinations for particle technologists. http://www.micromeritics.com/Library/Technical-Articles-Research-Applications.aspx. Accessed 19 Mar 2014

Webb PA (2001) An introduction to the physical characterization of materials by mercury intrusion porosimetry with emphasis on reduction and presentation of experimental data. http://www.micromeritics.com/Library/Technical-Articles-Research-Applications.aspx. Accessed 19 Mar 2014

Idris A, Khalid K, Omar W (2004) Drying of silica sludge using microwave heating. Appl Therm Eng 24:905–918. doi:10.1016/j.applthermaleng.2003.10.001

Araszkiewicz M, Koziol A, Oskwarek A, Lupinski M (2004) Microwave drying of porous materials. Dry Technol 22:2331–2341. doi:10.1081/DRT-200040014

Makul N, Rattanadecho P, Agrawal DK (2014) Applications of microwave energy in cement and concrete—a review. Renew Sustain Energy Rev 37:715–733. doi:10.1016/j.rser.2014.05.054

Angulo S (2005) Caracterização de agregados de resíduos de construção e demolição reciclados e a influência de suas características no comportamento de concretos. Universidade de São Paulo, São Paulo

Damineli BL (2007) Estudo de métodos para caracterização de propriedades físicas de agregados graúdos de resíduos de construção e demolição reciclados. Universidade de São Paulo, São Paulo

Taylor HFW (1997) Cement chemistry. Thomas Telford, London

Acknowledgments

Bruno Damineli’s work is supported by FAPESP (grant 2013/03688-3). Marco Quattrone’s work is supported by FAPESP (grant 2012/15195-9). Sergio Angulo’s work is supported by FAPESP (grant 2012/25496-6). The information and views set out in this study are those of the authors and do not necessarily reflect the opinion of FAPESP.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Damineli, B.L., Quattrone, M., Angulo, S.C. et al. Rapid method for measuring the water absorption of recycled aggregates. Mater Struct 49, 4069–4084 (2016). https://doi.org/10.1617/s11527-015-0773-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0773-5