Abstract

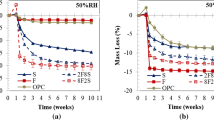

Considering the different hydration processes of concrete without accelerator, sprayed concrete with low-alkali accelerator not only presents short setting times and high early-age mechanical properties but also yields different hydration products. This study presents an analysis of the mechanical properties of concrete with and without accelerator and sprayed concrete with three water–binder (w/b) ratios and four dosages of fly ash (FA) after different curing ages. It also examines the setting time, mineral composition, thermogravimetric–differential scanning calorimetry curves and microscopic images of cement pastes with different accelerator amounts. Furthermore, the setting time and microstructure of accelerated sprayed concrete with different w/b ratios and FA contents are examined. Results show that the retarded action of gypsum disappears in the accelerated cement–accelerator–water system. C3A is quickly hydrated to form calcium aluminate hydrate (CAH) crystals, and a mesh structure is formed by ettringite, albite and CAH. A large amount of hydration heat improves the hydration rate of the cement clinker mineral and the resulting density, thereby improving mechanical properties at early curing ages. The setting times of the pastes increase with increasing w/b ratio and FA dosage. Thus, the hydration level, microstructure and morphology of the hydration products also change. Models of mechanical properties as functions of w/b, FA and curing age, as well as the relationship between compressive strength and splitting tensile strength, are established.

Similar content being viewed by others

References

Thomas A (2012) Sprayed concrete lined tunnel. Taylor and Francis, New York

Hemphill GB (2013) Practical tunnel construction. Wiley, Hoboken

Won J-P, Hwang U-J, Kim C-K, Lee S-J (2013) Mechanical performance of shotcrete made with a high-strength cement-based mineral accelerator. Concr Build Mater 2013(49):175–183

Prudêncio LR Jr (1998) Accelerating admixture for shotcrete. Cem Concr Compos 1998(20):213–219

Leung CKY, Lai R, Lee AYF (2005) Properties of wet-mixed fiber reinforced shotcrete and fiber reinforced concrete with similar composition. Cem Concr Res 2005(35):788–795

Jolin M, Beaupré D, Mindess S (1999) Tests to characterize properties of fresh dry-mix shotcrete. Cem Concr Res 1999(29):753–760

Li L, Wu A-x, Wang Y-m, Han B, Wang H-J, Wang C-l (2013) Mechanism of wet shotcrete interacting with rock in support system. J Cent South Univ 2013(20):821–829

Maltese C, Pistolesi C, Bravo A et al (2007) A case history: effect of moisture on the setting behavior of a Portland cement reacting with an alkali-free accelerator. Cem Concr Res 2007(37):856–865

Bullard JW, Jennings HM, Livingston RA et al (2011) Mechanisms of cement hydration. Rev Concr Res 2011(41):1208–1221

Lv P, Zhai J, Nie R et al (2004) Investigation on the early stage hydration of Portland cement using environmental scanning electron microscopy. J Chin Ceram Soc 2004(32):530–535 (in Chinese)

Jupe AC, Wilkinson AP, Funkhouser GP (2012) Simultaneous study of mechanical property development and early hydration chemistry in Portland cement slurries using X-ray diffraction and ultrasound reflection. Cem Concr Res 2012(48):1166–1173

Rikard Y, Jäglid U, Steenari B-M et al (2009) Early hydration and setting of Portland cement monitored by IR, SEM and Vicat techniques. Cem Concr Res 2009(39):433–439

Sun H, He Z, Gong A et al (2011) Influence of fly ash on microstructure of cement paste. Concrete 2011(33):79–82 (in Chinese)

Jiang L, Lin B, Cai T (1998) Study of hydration properties of cement binders with a large of fly ash. J Chin Ceram Soc 1998(26):695–701 (in Chinese)

Ou ZH, Ma BG, Jian SW (2011) Comparison of FT-IR, thermal analysis and XRD for determination of products of cement hydration. Adv Mater Res 168–170:518–522

Zeng Q, Li K, Fen-Chong T et al (2012) Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem Concr Res 2012(42):194–204

Hennings HM (2000) A model for the microstructure of calcium silicate hydrate in cement paste. Cem Concr Res 2000(30):101–116

Zhang G, Fang Y (1981) An analysis—how the composite aluminate type accelerator affects the behavior of the hydration of Portland cement. J Tongji Univ 1981(2):92–102 (in Chinese)

Liu C, Long S, Wu Y et al (2000) Study on the accelerating mechanism of accelerators in concrete. J Build Soc 2000(3):175–181 (in Chinese)

GB 175-2007. Common Portland cement

GB/T 1596-2005. Fly ash used for cement and concrete

GB 50086-2001. Specifications for bolt-shotcrete support

ASTM C191-08. Standard test methods for time of setting of hydraulic cement by Vicat needle

EN 14488-2-2006. Testing sprayed concrete. Part 2: compressive strength of young sprayed concrete

GB 50081-2002. Standard for method of mechanical properties on ordinary concrete

Niu D, Jiang L, Fei Q (2013) Deterioration mechanism of sulfate attack on concrete under freeze–thaw cycles. J Wuhan Univ Technol Mater Sci Ed 28:1172–1176

Mindess S, Young JF, Darwin D (2003) Concrete, 2nd edn. Pearson Education, Upper Saddle River, p 53

Acknowledgments

This research project was financially supported by National Natural Science Foundation of China (No. 51278403), and the Program for Changjiang Scholars and Innovative Research Team in University (IRT 13089).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Niu, D. & Zhang, Y. Microstructure and mechanical properties of accelerated sprayed concrete. Mater Struct 49, 1469–1484 (2016). https://doi.org/10.1617/s11527-015-0589-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0589-3