Abstract

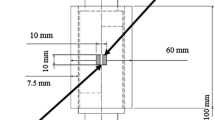

The objective of this work is focused in the accomplishment of Si3N4/Cu–Zn/AISI 304 joints and its interfacial study during liquid-state bonding. Sandwich type assemblies Si3N4/Cu–Zn/AISI 304 were produced at temperatures of 950 °C, 980 °C, and 1000 °C using different holding times (1–40 min) in argon atmosphere. The interfaces were characterized through SEM using EPMA in order to reveal the interaction between contact surfaces during joining process. The results showed that Si3N4 could not be bonded to AISI 304 at temperature lower than 1000 °C; however, successful joining was achieved at 1000 °C. Joining occurred by the formation of a reactive interface with several reaction products on the metal side of the joint. Shear testing gave a maximum joint strength of 66 MPa for Si3N4/Cu–Zn/AISI 304 samples produced at 1000 °C and 15 min, showing the intimate relationship between the interface and the joint strength.

Graphical abstract

Similar content being viewed by others

References

O. Tunckan, H. Yurdakul, S. Turan, Identification and quantification of reaction phases at Si3N4-Ti interfaces by using analytical transmission electron microscopy techniques. Ceram. Int. 39, 1087 (2013)

B.R. Golla, J.W. Ko, J.M. Kim, H.D. Kim, Effect of particle size and oxygen content of Si on processing, microstructure and thermal conductivity of sintered reaction bonded Si3N4. J. Alloys Compd. 595, 60 (2014)

J. Janczak-Rusch, G. Kaptay, L.P.H. Jeurgens, Interfacial design for joining technologies: an historical perspective. J. Mater. Eng. Perf. 23(5), 1608 (2014). https://doi.org/10.1007/s11665-014-0928-5

L. Lang, Z. Ren, J. Yu, Z. Yang, Y. Zhong, Microstructure and mechanical properties of partial transient liquid phase bonded Si3N4-DZ483 superalloy joints. Mater. Lett. 121, 223 (2014). https://doi.org/10.1016/j.matlet.2014.01.072

H. Firmanto, P. Hussain, O. Mamat, Reaction layers of the diffusion-bonded sialon and high-chromium steel. J. Appl. Sci. 11(10), 1809 (2011)

K. Martinsen, S.J. Hu, B.E. Carlson, Joining of dissimilar materials. CIRP Ann. Manuf. Technol. 64, 679 (2015). https://doi.org/10.1016/j.cirp.2015.05.006

X. Wu, R.S. Chandel, H. Li, H.P. Seow, S. Wu, Induction brazing of Inconel 718 to Inconel X-750 using Ni-Cr-Si-B amorphous foil. J. Mater. Proc. Technol. 104, 34 (2000)

C.F. Liu, J. Zhang, Y. Zhou, Q.C. Meng, M. Naka, Effect of Ti content on microstructure and strength of Si3N4/Si3N4 joints brazed with Cu-Pd-Ti filler metals. Mater. Sci. Eng. A 491, 483 (2008)

R.K. Roy, A.K. Panda, S.K. Das, Govind, A. Mitra. Development of a copper-based filler alloy for brazing stainless steels. Mater. Sci. Eng. A 523, 312 (2009)

L. Ceja-Cárdenas, J. Lemus-Ruiz, S.D. de la Torre, R. Escalona-González, Interfacial behavior in the brazing of silicon nitride joint using a Nb-foil interlayer. J. Mater. Proc. Technol. 213(3), 411 (2013). https://doi.org/10.1016/j.jmatprotec.2012.09.019

Z. Poniznik, Z. Nowak, M. Batista, Numerical modeling of deformation and fracture of reinforcing fibers in ceramic-metal composites. Int. J. Dam. Mech. 26, 711 (2017). https://doi.org/10.1177/1056789515611945

J.G. Flores, J. Cervantes, J. Lemus, Joining of silicon nitride to metal (Mo and Ti) using a Cu-foil interlayer. Mater Sci. For. 509, 99 (2006). https://doi.org/10.4028/www.scientific.net/MSF.509.99

J. Lemus-Ruiz, J.A. Verduzco, J. González-Sánchez, V.H. López, Characterization, shear strength and corrosion resistance of self joining AISI 304 using a Ni-Fe-Cr-Si metallic glass foil. J. Mater. Proc. Technol. 223, 16 (2015). https://doi.org/10.1016/j.jmatprotec.2015.03.038

Y. He, J. Zhang, P. Lv, Ch. Liu, Characterization of the Si3N4/42CrMo joints vacuum brazed with Pd modified filler alloy for high temperature application. Vacuum 109, 86 (2014). https://doi.org/10.1016/j.vacuum.2014.06.027

J. Lemus-Ruiz, L. Ceja-Cárdenas, E. Bedolla-Becerril, V.H. López-Morelos. Production, characterization, and mechanical evaluation of dissimilar metal/ceramic joints. Nanocomposites with unique properties and applications in medicine and industry. J. Cuppoletti (Ed.), InTech, Chap 10, 205 (2011).

G. Castro-Sánchez, C. I. Otero-Vázquez, J. Lemus-Ruiz, Fabrication and evaluation of hybrid components of WC/Inconel 600 by liquid state diffusion bonding. J. Mater. Sci. Eng. Adv. Technol. 16(1), 1 (2017). https://doi.org/10.18642/jmseat_7100121800

Acknowledgements

The authors would like to thank to Universidad Michoacana de San Nicolás de Hidalgo (UMSNH) and CONACYT Mexico for the facilities of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Data availability

The authors declare that the datasets generated during and/or analyzed during the current study are included in full in the results of this paper.

Rights and permissions

About this article

Cite this article

León-Gerónimo, Á., Miranda-Hernández, Q., Verduzco-Martínez, J.A. et al. Evaluation of Si3N4/AISI 304 steel joints produced by reactive brazing using Cu–Zn filler alloy. MRS Advances 6, 932–936 (2021). https://doi.org/10.1557/s43580-021-00183-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-021-00183-1