Abstract

Aluminum matrix syntactic foams (AMSFs) reinforced by Al2O3 hollow sphere (HS) with three different distributions of the particles were successfully produced by a self-developed counter-gravity infiltration casting technique. The effects of the size and distribution of particles on the quasi-static compressive behavior and failure mechanisms of the AMSFs was investigated. Microstructural images showed a clear interface between the fillers and matrix and no obvious shrinkage cavity was detected. The quasi-static compressive stress–strain curve of the AMSFs underwent three stages, namely linear-elastic, plateau, and then densification stages. The long plateau stage indicated that the AMSFs have excellent energy absorption capacity. The compressive strength and specific energy absorption capacity of the syntactic foam was lower when smaller particles were used and the compressive strength of bimodal AMSFs was much lower than that of monomodal AMSFs. The deformation of the AMSFs under compressive load, indicates that the distribution of the particles has an important influence on the failure mechanism of the AMSFs.

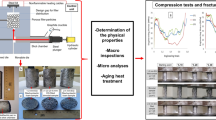

Graphical abstract

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as these data also form part of an ongoing study. The data are available from the corresponding author on reasonable request.

References

I.N. Orbulov, A. Szlancsik, On the mechanical properties of aluminum matrix syntactic foams. Adv. Eng. Mater. 20, 1700980 (2018)

L.O. Afolabi, Z.M. Ariff, S.F.S. Hashim, T. Alomayri, S. Mahzan, K.-A. Kamarudin, I.D. Muhammad, Syntactic foams formulations, production techniques, and industry applications: a review. J. Mater. Res. Technol. 9, 10698–10718 (2020)

Ç. Bolat, İ. C. AkgÜN, A. GÖKsenlİ, On the way to real applications: Aluminum matrix syntactic foams. Euro. Mech. Sci. 4, 131–141 (2020)

I.N. Orbulov, A. Kemény, Á. Filep, Z. Gácsi, Compressive characteristics of bimodal aluminium matrix syntactic foams. Compos. Part A 124, 105479 (2019)

G.A. Rocha Rivero, B.F. Schultz, J.B. Ferguson, N. Gupta, P.K. Rohatgi, Compressive properties of al-a206/sic and mg-az91/sic syntactic foams. J. Mater. Res. 28, 2426–2435 (2013)

B. Katona, G. Szebényi, I.N. Orbulov, Fatigue properties of ceramic hollow sphere filled aluminium matrix syntactic foams. Mater. Sci. Eng. A 679, 350–357 (2017)

A. Szlancsik, B. Katona, A. Kemeny, D. Karoly, On the filler materials of metal matrix syntactic foams. Materials 12, 2023 (2019)

C. Wang, F. Jiang, S. Shao, T. Yu, C. Guo, Acoustic properties of 316l stainless steel hollow sphere composites fabricated by pressure casting. Metals 10, 1047 (2020)

A.D. Akinwekomi, Microstructural characterisation and corrosion behaviour of microwave-sintered magnesium alloy az61/fly ash microspheres syntactic foams. Heliyon 5, e01531 (2019)

A.D. Akinwekomi, J.A. Adebisi, A.A. Adediran, Compressive characteristics of aluminum-fly ash syntactic foams processed by microwave sintering. Metall. Mater. Trans. A 50, 4257–4260 (2019)

K.N. Braszczyńska-Malik, J. Kamieniak, Az91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 128, 209–216 (2017)

H. Puga, V.H. Carneiro, C. Jesus, J. Pereira, V. Lopes, Influence of particle diameter in mechanical performance of al expanded clay syntactic foams. Compos. Struct. 184, 698–703 (2018)

I.N. Orbulov, A. Szlancsik, A. Kemény, D. Kincses, Compressive mechanical properties of low-cost, aluminium matrix syntactic foams. Compos. Part A 135, 105923 (2020)

S. Broxtermann, M. Vesenjak, L. Krstulović-Opara, T. Fiedler, Quasi static and dynamic compression of zinc syntactic foams. J. Alloys Compd. 768, 962–969 (2018)

N. Movahedi, M. Vesenjak, L. Krstulović-Opara, I.V. Belova, G.E. Murch, T. Fiedler, Dynamic compression of functionally-graded metal syntactic foams. Compos. Struct. 261, 113308 (2021)

I.V.B.M. Taherishargh, G.E. Murch, T. Fiedler, Pumice/aluminium syntacticfoam. Mater. Sci. Eng. A 635, 102–108 (2015)

K. Al-Sahlani, S. Broxtermann, D. Lell, T. Fiedler, Effects of particle size on the microstructure and mechanical properties of expanded glass-metal syntactic foams. Mater. Sci. Eng. A 728, 80–87 (2018)

S. Broxtermann, M.M. Su, H. Hao, T. Fiedler, Comparative study of stir casting and infiltration casting of expanded glass-aluminium syntactic foams. J. Alloys Compd. 845, 155415 (2020)

Y. Lin, Q. Zhang, J. Chang, H. Wang, X. Feng, J. Wang, Microstructural characterization and compression mechanical response of glass hollow spheres/al syntactic foams with different mg additions. Mater. Sci. Eng. A 766, 138338 (2019)

Q. Zhang, Y. Lin, H. Chi, J. Chang, G. Wu, Quasi-static and dynamic compression behavior of glass cenospheres/5a03 syntactic foam and its sandwich structure. Compos. Struct. 183, 499–509 (2018)

V. Manakari, G. Parande, M. Doddamani, M. Gupta, Evaluation of wear resistance of magnesium/glass microballoon syntactic foams for engineering/biomedical applications. Ceram. Int. 45, 9302–9305 (2019)

G. Anbuchezhiyan, B. Mohan, D. Sathianarayanan, T. Muthuramalingam, Synthesis and characterization of hollow glass microspheres reinforced magnesium alloy matrix syntactic foam. J. Alloys Compd. 719, 125–132 (2017)

P. Kubelka, C. Kádár, N. Jost, Effect of the interface on the compressive properties of magnesium syntactic foams. Mater. Lett. 287, 129293 (2021)

L. Pan, Y. Yang, M.U. Ahsan, D.D. Luong, N. Gupta, A. Kumar, P.K. Rohatgi, Zn-matrix syntactic foams: Effect of heat treatment on microstructure and compressive properties. Mater. Sci. Eng. A 731, 413–422 (2018)

E. Linul, D. Lell, N. Movahedi, C. Codrean, T. Fiedler, Compressive properties of zinc syntactic foams at elevated temperatures. Compos. Part B 167, 122–134 (2019)

S. Pandey, A.N.C. Venkat, D.P. Mondal, J.D. Majumdar, A.K. Jha, H. Rao, H. Kumar, Effect of cenosphere size and volume fraction on the microstructure and deformation behavior of ti-cenosphere syntactic foam made through powder metallurgy route. Mater. Perform. Charac. 5, 20160021 (2016)

Q. Yang, B. Yu, H. Hu, G. Hu, Z. Miao, Y. Wei, W. Sun, Melt flow and solidification during infiltration in making steel matrix syntactic foams. Mater. Sci. Technol. 35, 1831–1839 (2019)

H. Sazegaran, A.-R. Kiani-Rashid, J.V. Khaki, Effects of sphere size on the microstructure and mechanical properties of ductile iron–steel hollow sphere syntactic foams. Int. J. Miner. Metall. Mater. 23, 676–682 (2016)

L. Pérez, M. Villalobos, C. Órdenes, R.A.L. Drew, C. Ruiz-Aguilar, I. Alfonso, Elastic modulus estimation for copper syntactic foams reinforced with iron hollow spheres of different wall thicknesses. J. Mater. Eng. Perform. 28, 100–106 (2018)

C. Qian, C. Liang, Z. He, W. Ji, Effect of layer thickness in layered aluminum matrix syntactic foam. Materials 12, 4172 (2019)

M. Taherishargh, E. Linul, S. Broxtermann, T. Fiedler, The mechanical properties of expanded perlite-aluminium syntactic foam at elevated temperatures. J. Alloys Compd. 737, 590–596 (2018)

C.S. Chaitanya, R.N. Rao, Surface failure of syntactic foams in sliding contact. Mater. Today: Proc. 15, 63–67 (2019)

A. Vishwakarma, D.P. Mondal, S. Birla, S. Das et al., Effect of cenosphere size on the dry sliding wear behaviour lm13-cenosphere syntactic foam. Tribol. Int. 110, 8–22 (2017)

A. Szlancsik, B. Katona, I.N. Orbulov, M. Taherishargh, T. Fiedler, Fatigue properties of ep/a356 aluminium matrix syntactic foams with different densities. IOP Confer. Ser.: Mater. Sci. Eng. 426, 012045 (2018)

B. Katona, A. Szlancsik, T. Tábi, I.N. Orbulov, Compressive characteristics and low frequency damping of aluminium matrix syntactic foams. Mater. Sci. Eng. A 739, 140–148 (2019)

Y. Zhang, Y. Zhao, Hysteretic energy dissipation in aluminium matrix syntactic foam under intermittent cyclic compression. Materialia 6, 100286 (2019)

C. Kadar, F. Chmelik, D. Ugi, K. Mathis, M. Knapek, Damage characterization during compression in a perlite-aluminum syntactic foam. Materials 12, 3342 (2019)

M.J. Nayyeri, S.M.H. Mirbagheri, Evaluation of failure mechanisms of high strength tailor-made metallic foams (TMFs). Mater. Lett. 185, 89–91 (2016)

Q. Yu, Y. Zhao, A. Dong, Y. Li, Preparation and properties of c/c hollow spheres and the energy absorption capacity of the corresponding aluminum syntactic foams. Materials 11, 997 (2018)

A. Kemény, B. Leveles, T. Bubonyi, I.N. Orbulov, Effect of particle size and volume ratio of ceramic hollow spheres on the mechanical properties of bimodal composite metal foams. Compos. Part A 140, 106152 (2021)

N. Movahedi, G.E. Murch, I.V. Belova, T. Fiedler, Functionally graded metal syntactic foam: fabrication and mechanical properties. Mater. Design 168, 107652 (2019)

A. Pandey, S. Birla, D.P. Mondal, S. Das, V.A.N. Ch, Compressive deformation behavior and strain rate sensitivity of al-cenosphere hybrid foam with mono-modal, bi-modal and tri-modal cenosphere size distribution. Mater. Charact. 144, 563–574 (2018)

M. Cao, F. Jiang, C. Guo, Y. Li, T. Yu, R. Qin, Interface characterization and mechanical property of an aluminum matrix syntactic foam with multi-shelled hollow sphere structure. Ceram. Int. 48, 1882–18833 (2022)

K.N. Braszczyńska-Malik, J. Kamieniak, Analysis of interface between components in az91 magnesium alloy foam composite with ni-p coated fly ash cenospheres. J. Alloys Compd. 720, 352–359 (2017)

ISO 13314:2011—Mechanical testing of metals—ductility testing—compression test for porous and cellular metals (2011)

N. Movahedi, S.M.H. Mirbagheri, Comparison of the energy absorption of closed-cell aluminum foam produced by various foaming agents. Strength Mater. 48, 444–449 (2016)

I. Duarte, M. Vesenjak, L. Krstulović-Opara, Compressive behaviour of unconstrained and constrained integral-skin closed-cell aluminium foam. Compos. Struct. 154, 231–238 (2016)

M. HeidariGhaleh, N. Ehsani, H.R. Baharvandi, Compressive properties of a356 closed-cell aluminum foamed with a caco3 foaming agent without stabilizer particles. Met. Mater. Int. 27, 3856–3861 (2020)

N. Movahedi, E. Linul, L. Marsavina, The temperature effect on the compressive behavior of closed-cell aluminum-alloy foams. J. Mater. Eng. Perform. 27, 99–108 (2017)

Funding

This work is funded by the Guangdong Major Project of Basic and Applied Basic Research (2021B0301030002), Basic and Applied Basic Research Fund Project of Guangdong Province (2021A1515110333), Liaoning Province Applied Basic Research Program Project (2023JH2/101600064).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mei, Y., Fu, C., Fu, Y. et al. Effect of particle size and distribution of hollow spheres on the compressive behavior of aluminum matrix syntactic foams. Journal of Materials Research 38, 4408–4419 (2023). https://doi.org/10.1557/s43578-023-01153-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01153-z