Abstract

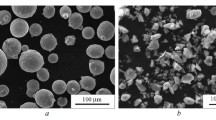

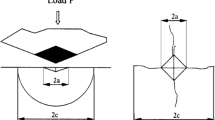

This study aimed to investigate the densification, microstructural, mechanical, and tribological properties of TiB2–NiCr composite. TiB2–NiCr composite was fabricated by spark plasma sintering (SPS) at different sintering temperatures ranging between 800 and 900 °C. The relative density of TiB2–NiCr composite increased by increasing SPS temperature, reaching a maximum for the composite sintered at 900 °C (~ 96.5%). The dry sliding wear performance of TiB2–NiCr composite was studied in the temperature range of 25–600 °C. Worn surface was analyzed by scanning electron microscopy (SEM) equipped with an energy dispersive X-ray spectrometer (EDS). The wear rate decreased with increasing SPS temperature. The higher densification, achieved by increasing SPS temperature resulted in lower porosity, better interfacial bonding, and higher hardness, all of which decreased the wear rate of the composite. The high-temperature wear behavior of composite showed promising performance. This study suggested that sintered TiB2–NiCr composites could be promising for wear resistance applications at elevated temperatures.

Graphical abstract

The effects of SPS temperature on densification, microstructural, mechanical, and tribological behavior of TiB2–NiCr composite over a wide temperature range

Similar content being viewed by others

References

A.H. Navidpour, M. Fakhrzad, Photocatalytic activity of Zn2SnO4 coating deposited by air plasma spraying. Appl. Surf. Sci. Adv. 6, 100153 (2021)

A.H. Navidpour, A. Hosseinzadeh, J.L. Zhou, Z. Huang, Progress in the application of surface engineering methods in immobilizing TiO2 and ZnO coatings for environmental photocatalysis. Catal. Rev. Sci. Eng. (2021). https://doi.org/10.1080/01614940.2021.1983066

A.H. Navidpour, M. Salehi, H.R. Salimijazi, Y. Kalantari, M. Azarpour Siahkali, Photocatalytic activity of flame-sprayed coating of zinc ferrite powder. J. Therm. Spray. Technol. 26, 2030–2039 (2017)

A.H. Navidpour, Y. Kalantari, M. Salehi, M. Amirnasr, M. Rismanchian, M. Azarpour Siahkali, Plasma-sprayed photocatalytic zinc oxide coatings. J. Therm. Spray. Technol. 26, 717–727 (2017)

A.H. Navidpour, M. Salehi, M. Amirnasr, M. AzarpourSiahkal, Y. Kalantari, M. Mohammadnezhad, Photocatalytic iron oxide coatings produced by thermal spraying process. J. Therm. Spray. Technol. 24, 1487–1497 (2015)

A.H. Navidpour, M. Fakhrzad, M. Tahari, Novel photocatalytic coatings based on tin oxide semiconductor. Surf. Eng. 35(3), 216–226 (2019)

S. Nekahi, F. Sadegh Moghanlou, M. Vajdi, Z. Ahmadi, A. Motallebzadeh, M. Shahedi Asl, Microstructural, thermal and mechanical characterization of TiB2–SiC composites doped with short carbon fibers. Int. J. Refract. Hard. Met. 82, 129–135 (2019)

Z. Hamidzadeh Mahaseni, M. Dashti Germi, Z. Ahmadi, M. Shahedi Asl, Microstructural investigation of spark plasma sintered TiB2 ceramics with Si3N4 addition. Ceram. Int. 44(11), 13367–13372 (2018)

F. Shayesteh, S.A. Delbari, Z. Ahmadi, M. Shokouhimehr, M. Shahedi Asl, Influence of TiN dopant on microstructure of TiB2 ceramic sintered by spark plasma. Ceram. Int. 45(5), 5306–5311 (2019)

G.B. Raju, B. Basu, Development of high temperature TiB2-based ceramics. Key. Eng. Mater. 395, 89–124 (2009)

T.S.R.C.H. Murthy, J.K. Sonber, K. Sairam, R.D. Bedse, J.K. Chakarvartty, Development of refractory and rare earth metal borides and carbides for high temperature applications. Mater. Today. Proc. 3(9), 3104–3113 (2016)

J.H. Park, Y.H. Lee, Y.H. Koh, H.E. Kim, S. Su Baek, Effect of hot-pressing temperature on densification and mechanical properties of titanium diboride with silicon nitride as a sintering aid. J. Am. Ceram. Soc. 83(6), 1542–1544 (2004)

M. Barandika, J. Sánchez, T. Rojo, R. Cortés, F. Castro, Fe-Ni-Ti binder phases for TiB2-based cermets: a thermodynamic approach. Scr. Mater. 39, 1395–1400 (1998)

T. Zhang, S. Song, C. Xie, G. He, B. Xing, R. Li, Q. Zhen, Preparation of highly-dense TiB2 ceramic with excellent mechanical properties by spark plasma sintering using hexagonal TiB2 plates. Mater. Res. Express 6, 125055 (2019)

J. Park, Y. Koh, H. Kim, C. Hwang, E. Kang, Densification and mechanical properties of titanium diboride with silicon nitride as a sintering aid. J. Am. Ceram. Soc. 82(11), 3037–3042 (2004)

S. Torizuka, K. Sato, H. Nishio, T. Kishi, Effect of SiC on interfacial reaction and sintering mechanism of TiB2. J. Am. Ceram. Soc. 78(6), 1606–1610 (1995)

S. Baik, P.F. Becher, Effect of oxygen contamination on densification of TiB2. J. Am. Ceram. Soc. 70(8), 527–530 (1987)

G. Zhao, C. Huang, H. Liu, B. Zou, H. Zhu, J. Wang, A study on in-situ synthesis of TiB2–SiC ceramic composites by reactive hot pressing. Ceram. Int. 40(1), 2305–2313 (2014)

S.K. Bhaumik, C. Divakar, A.K. Singh, G.S. Upadhyaya, Synthesis and sintering of TiB2 and TiB2–TiC composite under high pressure. Mater. Sci. Eng. A 279(1), 275–281 (2000)

N.A. Sabahi, M. Azadbeh, A.M. Shahedi, Effects of in-situ formed TiB whiskers on microstructure and mechanical properties of spark plasma sintered Ti–B4C and Ti–TiB2 composites. Sci. Iran 25, 762–771 (2018)

M. Akhlaghi, S.A. Tayebifard, E. Salahi, A.M. Shahedi, Spark plasma sintering of TiAl–Ti3AlC2 composite. Ceram. Int. 44(17), 21759–21764 (2018)

Z.A. Munir, U. Anselmi-Tamburini, M. Ohyanagi, The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. J. Mater. Sci. 41, 763–777 (2006)

M. Suarez, A. Fernandez, J.L. Menendez, R. Torrecillas, J. Hennicke, R. Kirchner, U.H. Kessel, Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. Sinter. Appl. 13, 319–342 (2013)

D.V. Dudina, B.B. Bokhonov, E.A. Olevsky, Fabrication of porous materials by spark plasma sintering: a review. Materials 12(3), 541 (2019)

M. Abedi, S. Sovizi, A. Azarniya, D. Giuntini, M.E. Seraji, H.R.M. Hosseini, C. Amutha, S. Ramakrishna, A. Mukasyan, An analytical review on spark plasma sintering of metals and alloys: from processing window, phase transformation, and property perspective. Crit. Rev. Solid State Mater. Sci. (2022). https://doi.org/10.1080/10408436.2022.2049441

A. Bellosi, M. Frédéric, S. Diletta, Fast densification of ultra-high-temperature ceramics by spark plasma sintering. Int. J. Appl. Ceram. Technol. 3(1), 32–40 (2006)

Z. Zhang, X. Shen, F. Wang, S. Lee, L. Wang, Densification behavior and mechanical properties of the spark plasma sintered monolithic TiB2 ceramics. Mater. Sci. Eng. A 527(21), 5947–5951 (2010)

M. ShahediAsl, Z. Ahmadi, S. Parvizi, Z. Balak, I. Farahbakhsh, Contribution of SiC particle size and spark plasma sintering conditions on grain growth and hardness of TiB2 composites. Ceram. Int. 43(16), 13924–1393 (2017)

S. Tian, Z. Liao, W. Guo, Q. He, H. Wang, W. Wang, Effects of theTiB2–SiC volume ratio and spark plasma sintering temperature on the properties and microstructure of TiB2–BN–SiC composite ceramics. Crystals 12, 29 (2021)

F. Ghafuri, M. Ahmadian, R. Emadi, M. Zakeri, Effects of SPS parameters on the densification and mechanical properties of TiB2-SiC composite. Ceram. Int. 45(8), 10550–10557 (2019)

S. Oguntuyi, O. Johnson, M. Shongwe, Spark plasma sintering of ceramic matrix composite of ZrB2 and TiB2: microstructure, densification, and mechanical properties—a review. Met. Mater. Int. 27, 2146–2159 (2020)

Z. Ahmadi, B. Nayebi, M. Shahedi Asl, I. Farahbakhsh, Z. Balak, Densification improvement of spark plasma sintered TiB2-based composites with micron-, submicron- and nano-sized SiC particulates. Ceram. Int. 44(10), 11431–11437 (2018)

G. Raju, B. Basu, Densification, sintering reactions, and properties of titanium diboride with titanium disilicide as a sintering aid. J. Am. Ceram. Soc. 90(11), 3415–3423 (2007)

M. Dashti Germi, Z. Hamidzadeh Mahaseni, Z. Ahmadi, M. Shahedi Asl, Phase evolution during spark plasma sintering of novel Si3N4-doped TiB2–SiC composite. Mater. Charact. 145, 225–232 (2018)

L. Júnior, Í. Tomaz, M. Oliveira, L. Simão, S. Monteiro, Development and evaluation of TiB2–AlN ceramic composites sintered by spark plasma. Ceram. Int. 42(16), 18718–18723 (2016)

Z. Li, H. Yu, D. Sun, Structural and microstructural effects produced by microwave sintering over La2O3 doped TiB2–Ni composites. Ceram. Int. 47(19), 26692–26703 (2021)

M. Wang, W. Wang, J. Zhou, H. Chen, Z. Chang, The fabrication and characterization of a TiB2/Ni composite using spark plasma sintering. Trans. Indian Inst. Met. 71, 2349–2360 (2018)

M. Vlasova, A. Bykov, M. Kakazey, P. Aguilar, I. Melnikov, I. Rosales, R. Tapia, Formation and properties of TiB2–Ni composite ceramics. Sci. Sinter. 48, 137–146 (2016)

G. Zhao, J. Wang, Y. Deng, T. Yan, W. Liang, T. Li, L. Zhang, Q. Jia, Y. Wan, The study of the tribological properties of TiB2/Cr multilayered coatings over a wide temperature range. J. Mater. Res. Technol. 16, 290–301 (2022)

Z. Zhang, X. Shen, F. Wang, S. Lee, Q. Fan, M. Cao, Low-temperature densification of TiB2 ceramic by the spark plasma sintering process with Ti as a sintering aid. Scr. Mater. 66(3), 167–170 (2012)

C. Yang, H. Guo, D. Mo, S. Qu, X. Li, W. Zhang, L. Zhang, Bulk TiB2–Based ceramic composites with improved mechanical property using Fe–Ni–Ti–Al as a sintering aid. Mater. 7(10), 7105–7117 (2014)

A. Horlock, D. McCartney, P. Shipway, J. Wood, Thermally sprayed Ni(Cr)–TiB2 coatings using powder produced by self-propagating high temperature synthesis: microstructure and abrasive wear behavior. Mater. Sci. Eng. A 336(1), 88–98 (2002)

B. Lotfi, P. Shipway, D. McCartney, H. Edris, Abrasive wear behavior of Ni(Cr)–TiB2 coatings deposited by HVOF spraying of SHS-derived cermet powders. Wear 254(3), 340–349 (2003)

N. Zhang, N. Zhang, X. Wei, Y. Zhang, D. Li, Microstructure and tribological performance of TiB2–NiCr composite coating deposited by APS. Coatings 7(12), 238 (2017)

N. Zhang, N. Zhang, S. Guan, S. Li, G. Zhang, Y. Zhang, Composition versus wear behavior of air plasma sprayed NiCr–TiB2–ZrB2 composite coating. Coatings 8(8), 273 (2018)

Z. Zhao, H. Li, T. Yang, H. Zhu, Tribological properties of HVOF-sprayed TiB2–NiCr coatings with agglomerated feedstocks. J. Therm. Spray. Technol. 27, 718–726 (2018)

L. Nikzad, R. Licheri, T. Ebadzadeh, R. Orrù, G. Cao, Effect of ball milling on reactive spark plasma sintering of B4C–TiB2 composites. Ceram. Int. 38(8), 6469–6480 (2012)

A. Jam, L. Nikzad, M. Razavi, TiC-based cermet prepared by high-energy ball-milling and reactive spark plasma sintering. Ceram. Int. 43(2), 2448–2455 (2017)

A. Locci, R. Orrù, G. Cao, Z. Munir, Effect of ball milling on simultaneous spark plasma synthesis and densification of TiC–TiB2 composites. Mater. Sci. Eng. A 434(1), 23–29 (2006)

M. Abdolahpour Salari, G. Merhan Muğlu, M. Rezaei, M. Saravana Kumar, H. Pulikkalparambil, S. Siengchin, In-situ synthesis of TiN and TiB2 compounds during reactive spark plasma sintering of BN–Ti composites. Sci. Sinter. 1(1), 48–53 (2021)

Y.H. Koh, S.Y. Lee, H.E. Kim, Oxidation behavior of titanium boride at elevated temperatures. J. Am. Ceram. Soc. 84(1), 239–241 (2001)

T. Murthy, J. Sonber, C. Subramanian, R. Hubli, N. Krishnamurthy, A. Suri, Densification and oxidation behavior of a novel TiB2–MoSi2–CrB2 composite. Int. J. Refract. Metal Hard Mater. 36, 243–253 (2013)

C. Wu, Y. Li, X. Cheng, S. Xie, Microstructural evolution and oxidation behavior of TiB2SiC B4C composite fabricated by reactive spark plasma sintering. J. Alloys Compd. 765, 158–165 (2018)

Z. Ahmadi, Z. Hamidzadeh Mahaseni, M. Dashti Germi, M. Shahedi Asl, Microstructure of spark plasma sintered TiB2 and TiB2–AlN ceramics. Adv. Ceram. Prog. 5(1), 36–40 (2019)

S. Nekahi, F. Sadegh Moghanlou, M. Vajdi, Z. Ahmadi, A. Motallebzadeh, M. Shahedi Asl, Microstructural, thermal and mechanical characterization of TiB2–SiC composites doped with short carbon fibers. Int. J. Refract Met. Hard Mater. 82, 129–135 (2019)

F. Sadegh Moghanlou, S. Nekahi, M. Vajdi, Z. Ahmadi, A. Motallebzadeh, A. Shokouhimehr, M. Shokouhimehr, S. Jafargholinejad, M. Shahedi Asl, Effects of graphite nano-flakes on thermal and microstructural properties of TiB2–SiC composites. Ceram. Int. 46(8), 11622–11630 (2020)

T. Nguyen, Z. Hamidzadeh Mahaseni, M. Dashti Germi, S. Delbari, Q. Le, Z. Ahmadi, M. Shokouhimehr, M. Shahedi, A. Namini, Densification behavior and microstructure development in TiB2 ceramics doped with h-BN. Ceram. Int. 46(11), 18970–18975 (2020)

D. King, W. Fahrenholtz, G. Hilmas, Microstructural effects on the mechanical properties of SiC-15 vol% TiB2 particulate-reinforced ceramic composites. J. Am. Ceram. Soc. 96(2), 577–583 (2012)

S. Oguntuyi, M. Shongwe, L. Tshabalala, O. Johnson, N. Malatji, Effects of SiC on the microstructure, densification, hardness and wear performance of TiB2 ceramic matrix composite consolidated via spark plasma sintering. Arab. J. Sci. Eng. (2021). https://doi.org/10.1007/s13369-022-07026-7

Z. Zhang, Y. Chen, L. Zuo, Y. Zhang, Y. Qi, K. Gao, The effect of volume fraction of WC particles on wear behavior of in-situ WC/Fe composites by spark plasma sintering. Int. J. Refract. Hard. Met. 69, 196–208 (2017)

X. Wu, D. Wang, V. De Andrade, Y. Jiang, W. Wang, S. Wen, K. Gao, H. Huang, S. Chen, Z. Nie, Dry sliding wear of microalloyed Er-containing Al–10Sn–4Si–1Cu alloy. J. Mater. Res. Technol. 9(6), 14828–14840 (2020)

H. Wang, H. Li, H. Zhu, F. Cheng, D. Wang, Z. Li, A comparative study of plasma sprayed TiB2–NiCr and Cr3C2–NiCr composite coatings. Mater. Lett. 153, 110–113 (2015)

B. Nayebi, Z. Ahmadi, M. Shahedi Asl, S. Parvizi, M. Shokouhimehr, Influence of vanadium content on the characteristics of spark plasma sintered ZrB2–SiC–V composites. J. Alloys Compd. 805, 725–732 (2019)

N. Radhika, M.L.V. Priyanka, Investigation of adhesive wear behavior of zirconia reinforced aluminium metal matrix composite. J. Eng. Sci. Technol. Rev. 12(6), 1685–1696 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fakhrzad, M., Faramarzi, M., Navidpour, A.H. et al. Effects of spark plasma sintering temperature on the tribological performance of TiB2–NiCr composite. Journal of Materials Research 38, 2225–2238 (2023). https://doi.org/10.1557/s43578-023-00952-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-00952-8