Abstract

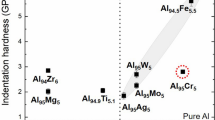

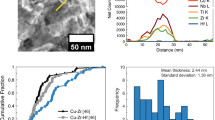

The deliberate use of solute enrichment at grain boundaries, otherwise known as segregation engineering, is a promising approach to tailor the properties of interface-dominated materials such as nanocrystalline alloys. The ensuing chemical and structural evolution at grain boundaries can give rise to thermal stability and excellent mechanical properties, but the interplay between enrichment, phase decomposition, grain growth, and mechanical behavior exists in a vast composition and processing space. In this study, a combinatorial synthesis and rapid characterization approach was applied to segregation-engineered nanocrystalline Al–Ni–Ce alloys to assess the evolution of microstructure and resulting mechanical behavior as functions of alloying content and annealing conditions. In addition to the identification of alloys and processing conditions that give rise to exceptional thermal stability, strength retention, and homogeneous plastic flow, we construct combined thermal stability and deformation mechanism maps that demarcate several important regimes of behavior.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

Code availability

Not applicable.

References

D. Raabe, M. Herbig, S. Sandlöbes, Y. Li, D. Tytko, M. Kuzmina, D. Ponge, P.-P. Choi, Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces. Curr. Opin. Solid State Mater. Sci. 18, 253–261 (2014). https://doi.org/10.1016/J.COSSMS.2014.06.002

T.J. Rupert, The role of complexions in metallic nano-grain stability and deformation. Curr. Opin. Solid State Mater. Sci. 20, 257–267 (2016). https://doi.org/10.1016/J.COSSMS.2016.05.005

T.J. Rupert, D.S. Gianola, Y. Gan, K.J. Hemker, Experimental observations of stress-driven grain boundary migration. Science 326, 1686–1690 (2009)

M.-R. He, S.K. Samudrala, G. Kim, P.J. Felfer, A.J. Breen, J.M.C. Cairney, D.S. Gianola, J.M.C. Cairney, Linking stress-driven microstructural evolution in nanocrystalline aluminium with grain boundary doping of oxygen. Nat Commun 7, 1–7 (2016). https://doi.org/10.1038/pj.2016.37

R.I. Babicheva, S.V. Dmitriev, L. Bai, Y. Zhang, S.W. Kok, G. Kang, K. Zhou, Effect of grain boundary segregation on the deformation mechanisms and mechanical properties of nanocrystalline binary aluminum alloys. Comput. Mater. Sci. 117, 445–454 (2016). https://doi.org/10.1016/j.commatsci.2016.02.013

H.A. Murdoch, C.A. Schuh, Estimation of grain boundary segregation enthalpy and its role in stable nanocrystalline alloy design. J. Mater. Res. 28, 2154–2163 (2019). https://doi.org/10.1557/jmr.2013.211

J.F. Nie, Y.M. Zhu, J.Z. Liu, X.Y. Fang, Periodic segregation of solute atoms in fully coherent twin boundaries. Science 340, 957–960 (2013). https://doi.org/10.1126/science.1229369

A. Devaraj, W. Wang, R. Vemuri, L. Kovarik, X. Jiang, M. Bowden, J.R.R. Trelewicz, S. Mathaudhu, A. Rohatgi, Grain boundary segregation and intermetallic precipitation in coarsening resistant nanocrystalline aluminum alloys. Acta Mater. 165, 698–708 (2019). https://doi.org/10.1016/j.actamat.2018.09.038

K.A. Darling, M. Rajagopalan, M. Komarasamy, M.A. Bhatia, B.C. Hornbuckle, R.S. Mishra, K.N. Solanki, Extreme creep resistance in a microstructurally stable nanocrystalline alloy. Nature 537, 378–381 (2016). https://doi.org/10.1038/nature19313

T. Frolov, K.A. Darling, L.J. Kecskes, Y. Mishin, Stabilization and strengthening of nanocrystalline copper by alloying with tantalum. Acta Mater. 60, 2158–2168 (2012). https://doi.org/10.1016/J.ACTAMAT.2012.01.011

C.C. Koch, R.O. Scattergood, K.A. Darling, J.E. Semones, Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43, 7264–7272 (2008). https://doi.org/10.1007/s10853-008-2870-0

K.A. Darling, B.K. VanLeeuwen, C.C. Koch, R.O. Scattergood, Thermal stability of nanocrystalline Fe-Zr alloys. Mater. Sci. Eng. A 527, 3572–3580 (2010). https://doi.org/10.1016/j.msea.2010.02.043

Y. Hu, T.J. Rupert, Atomistic modeling of interfacial segregation and structural transitions in ternary alloys. J. Mater. Sci. 54, 3975–3993 (2019). https://doi.org/10.1007/s10853-018-3139-x

W. Xing, A.R. Kalidindi, D. Amram, C.A. Schuh, Solute interaction effects on grain boundary segregation in ternary alloys. Acta Mater. 161, 285–294 (2018). https://doi.org/10.1016/j.actamat.2018.09.005

A.L. Vasiliev, M. Aindow, M.J. Blackburn, T.J. Watson, Phase stability and microstructure in devitrified Al-rich Al-Y-Ni alloys. Intermetallics 12, 349–362 (2004). https://doi.org/10.1016/j.intermet.2003.11.007

Y.H. Gao, L.F. Cao, J. Kuang, H. Song, G. Liu, J.Y. Zhang, J. Sun, Solute repositioning to tune the multiple microalloying effects in an Al–Cu alloy with minor Sc, Fe and Si addition. Mater. Sci. Eng. A 803, 140509 (2021). https://doi.org/10.1016/j.msea.2020.140509

C.M. Grigorian, T.J. Rupert, Thick amorphous complexion formation and extreme thermal stability in ternary nanocrystalline Cu-Zr-Hf alloys. Acta Mater. 179, 172–182 (2019)

J.D. Schuler, T.J. Rupert, Materials selection rules for amorphous complexion formation in binary metallic alloys. Acta Mater. 140, 196–205 (2017)

A. Khalajhedayati, T.J. Rupert, High-temperature stability and grain boundary complexion formation in a nanocrystalline Cu-Zr alloy. JOM 67, 2788–2801 (2015). https://doi.org/10.1007/s11837-015-1644-9

G.H. Balbus, F. Wang, D.S. Gianola, Suppression of shear localization in nanocrystalline Al–Ni–Ce via segregation engineering. Acta Mater. 188, 63–78 (2020). https://doi.org/10.1016/j.actamat.2020.01.041

G.H. Balbus, J. Kappacher, D.J. Sprouster, F. Wang, J. Shin, Y.M. Eggeler, T.J. Rupert, J.R. Trelewicz, D. Kiener, V. Maier-Kiener, D.S. Gianola, Disordered interfaces enable high temperature thermal stability and strength in a nanocrystalline aluminum alloy. Acta Mater. (2021). https://doi.org/10.1016/j.actamat.2021.116973

F. Liu, R. Kirchheim, Nano-scale grain growth inhibited by reducing grain boundary energy through solute segregation. J. Cryst. Growth 264, 385–391 (2004). https://doi.org/10.1016/j.jcrysgro.2003.12.021

R. Kirchheim, Grain coarsening inhibited by solute segregation. Acta Mater. 50, 413–419 (2002). https://doi.org/10.1016/S1359-6454(01)00338-X

J. Weissmüller, Alloy effects in nanostructures. Nanostruct. Mater. 3, 261–272 (1993). https://doi.org/10.1016/0965-9773(93)90088-S

T. Chookajorn, H.A. Murdoch, C.A. Schuh, Design of stable nanocrystalline alloys. Science 337, 951–954 (2012). https://doi.org/10.1126/science.1224737

J.R. Trelewicz, C.A. Schuh, Grain boundary segregation and thermodynamically stable binary nanocrystalline alloys. Phys. Rev. 79, 094112 (2009). https://doi.org/10.1103/PhysRevB.79.094112

C.E. Krill III., R. Klein, S. Janes, R. Birringer, Thermodynamic stabilization of grain boundaries in nanocrystalline alloys. Mater. Sci. Forum 179–181, 443–448 (1995). https://doi.org/10.4028/www.scientific.net/MSF.179-181.443

M. Saber, H. Kotan, C.C. Koch, R.O. Scattergood, Thermodynamic stabilization of nanocrystalline binary alloys. J. Appl. Phys. 113, 063515 (2013). https://doi.org/10.1063/1.4791704

K.A. Darling, M.A. Tschopp, R.K. Guduru, W.H. Yin, Q. Wei, L.J. Kecskes, Microstructure and mechanical properties of bulk nanostructured Cu–Ta alloys consolidated by equal channel angular extrusion. Acta Mater. 76, 168–185 (2014). https://doi.org/10.1016/J.ACTAMAT.2014.04.074

A. Michels, C.E. Krill, H. Ehrhardt, R. Birringer, D.T. Wu, Modelling the influence of grain-size-dependent solute drag on the kinetics of grain growth in nanocrystalline materials. Acta Mater. 47, 2143–2152 (1999). https://doi.org/10.1016/S1359-6454(99)00079-8

M. Rajagopalan, K. Darling, S. Turnage, R.K. Koju, B. Hornbuckle, Y. Mishin, K.N. Solanki, Microstructural evolution in a nanocrystalline Cu-Ta alloy: A combined in-situ TEM and atomistic study. Mater. Des. 113, 178–185 (2017). https://doi.org/10.1016/j.matdes.2016.10.020

M.A. Atwater, R.O. Scattergood, C.C. Koch, The stabilization of nanocrystalline copper by zirconium. Mater. Sci. Eng.: A 559, 250–256 (2013). https://doi.org/10.1016/j.msea.2012.08.092

R.K. Koju, K.A. Darling, K.N. Solanki, Y. Mishin, Atomistic modeling of capillary-driven grain boundary motion in Cu-Ta alloys. Acta Mater. (2018). https://doi.org/10.1016/j.actamat.2018.01.027

P.R. Cantwell, M. Tang, S.J. Dillon, J. Luo, G.S. Rohrer, M.P. Harmer, Grain boundary complexions. Acta Mater. 62, 1–48 (2014). https://doi.org/10.1016/j.actamat.2013.07.037

S.J. Dillon, M. Tang, W.C. Carter, M.P. Harmer, Complexion: A new concept for kinetic engineering in materials science. Acta Mater. 55, 6208–6218 (2007). https://doi.org/10.1016/J.ACTAMAT.2007.07.029

J.D. Schuler, O.K. Donaldson, T.J. Rupert, Amorphous complexions enable a new region of high temperature stability in nanocrystalline Ni-W. Scr. Mater. 154, 49–53 (2018). https://doi.org/10.1016/J.SCRIPTAMAT.2018.05.023

G. Sha, L. Yao, X. Liao, S.P. Ringer, Z.C. Duan, T.G. Langdon, Segregation of solute elements at grain boundaries in an ultrafine grained Al–Zn–Mg–Cu alloy. Ultramicroscopy 111, 500–505 (2011). https://doi.org/10.1016/J.ULTRAMIC.2010.11.013

M. Hans, P. Keuter, A. Saksena, J.A. Sälker, M. Momma, H. Springer, J. Nowak, D. Zander, D. Primetzhofer, J.M. Schneider, Opportunities of combinatorial thin film materials design for the sustainable development of magnesium-based alloys. Sci. Rep. (2021). https://doi.org/10.1038/s41598-021-97036-6

R. Pei, Y. Zou, D. Wei, T. Al-Samman, Grain boundary co-segregation in magnesium alloys with multiple substitutional elements. Acta Mater. 208, 116749 (2021). https://doi.org/10.1016/j.actamat.2021.116749

C.Y. Wang, L.W. Yang, Y.W. Cui, M.T. Pérez-Prado, High throughput analysis of solute effects on the mechanical behavior and slip activity of beta titanium alloys. Mater. Des. 137, 371–383 (2018). https://doi.org/10.1016/J.MATDES.2017.10.029

R. Schoeppner, C. Ferguson, L. Pethö, C. Guerra-Nuñez, A.A. Taylor, M. Polyakov, B. Putz, J.M. Breguet, I. Utke, J. Michler, Interfacial adhesion of alumina thin films over the full compositional range of ternary fcc alloy films: A combinatorial nanoindentation study. Mater. Des. 193, 108802 (2020). https://doi.org/10.1016/j.matdes.2020.108802

S.-I. Jun, P.D. Rack, T.E. McKnight, A.V. Melechko, M.L. Simpson, Electrical and microstructural characterization of molybdenum tungsten electrodes using a combinatorial thin film sputtering technique. J. Appl. Phys. 97, 054906 (2005). https://doi.org/10.1063/1.1855395

T. Iwasaki, N. Itagaki, T. Den, H. Kumomi, K. Nomura, T. Kamiya, H. Hosono, Combinatorial approach to thin-film transistors using multicomponent semiconductor channels: An application to amorphous oxide semiconductors in In–Ga–Zn–O system. Appl. Phys. Lett. 90, 242114 (2007). https://doi.org/10.1063/1.2749177

P. Ziolkowski, M. Wambach, A. Ludwig, E. Mueller, Application of high-throughput seebeck microprobe measurements on thermoelectric half-Heusler thin film combinatorial material libraries. ACS Comb. Sci. 20, 1–18 (2018). https://doi.org/10.1021/acscombsci.7b00019

R. Collette, Y. Wu, A. Olafsson, J.P. Camden, P.D. Rack, Combinatorial thin film sputtering AuxAl1–x alloys: Correlating composition and structure with optical properties. ACS Comb. Sci. 20, 633–642 (2018). https://doi.org/10.1021/ACSCOMBSCI.8B00091

A. Ludwig, N. Zotov, A. Savan, S. Groudeva-Zotova, Investigation of hard magnetic properties in the Fe–Pt system by combinatorial deposition of thin film multilayer libraries. Appl. Surf. Sci. 252, 2518–2523 (2006). https://doi.org/10.1016/J.APSUSC.2005.04.058

A. Marshal, K.G. Pradeep, D. Music, L. Wang, O. Petracic, J.M. Schneider, Combinatorial evaluation of phase formation and magnetic properties of FeMnCoCrAl high entropy alloy thin film library. Sci. Rep. (2019). https://doi.org/10.1038/s41598-019-44351-8

J. Li, F.S. Gittleson, Y. Liu, J. Liu, A.M. Loye, L. McMillon-Brown, T.R. Kyriakides, J. Schroers, A.D. Taylor, Exploring a wider range of Mg–Ca–Zn metallic glass as biocompatible alloys using combinatorial sputtering. Chem. Commun. 53, 8288–8291 (2017). https://doi.org/10.1039/C7CC02733H

J.M. Gregoire, P.J. McCluskey, D. Dale, S. Ding, J. Schroers, J.J. Vlassak, Combining combinatorial nanocalorimetry and X-ray diffraction techniques to study the effects of composition and quench rate on Au–Cu–Si metallic glasses. Scr. Mater. 66, 178–181 (2012). https://doi.org/10.1016/J.SCRIPTAMAT.2011.10.034

J.H. Yao, C. Hostert, D. Music, A. Frisk, M. Björck, J.M. Schneider, Synthesis and mechanical properties of Fe–Nb–B thin-film metallic glasses. Scr. Mater. 67, 181–184 (2012). https://doi.org/10.1016/J.SCRIPTAMAT.2012.04.011

S. Ding, J. Gregoire, J.J. Vlassak, J. Schroers, Solidification of Au-Cu-Si alloys investigated by a combinatorial approach. J. Appl. Phys. 111, 114901 (2012). https://doi.org/10.1063/1.4722996

A. Marshal, K.G. Pradeep, D. Music, S. Zaefferer, P.S. De, J.M. Schneider, Combinatorial synthesis of high entropy alloys: Introduction of a novel, single phase, body-centered-cubic FeMnCoCrAl solid solution. J. Alloys Compd. 691, 683–689 (2017). https://doi.org/10.1016/J.JALLCOM.2016.08.326

Z. Li, A. Ludwig, A. Savan, H. Springer, D. Raabe, Combinatorial metallurgical synthesis and processing of high-entropy alloys. J. Mater. Res. 33, 3156–3169 (2018). https://doi.org/10.1557/jmr.2018.214

S.A. Kube, S. Sohn, D. Uhl, A. Datye, A. Mehta, J. Schroers, Phase selection motifs in high entropy alloys revealed through combinatorial methods: Large atomic size difference favors BCC over FCC. Acta Mater. 166, 677–686 (2019). https://doi.org/10.1016/J.ACTAMAT.2019.01.023

D.B. Miracle, M. Li, Z. Zhang, R. Mishra, K.M. Flores, Emerging capabilities for the high-throughput characterization of structural materials. Annu. Rev. Mater. Res. 51, 131–164 (2021). https://doi.org/10.1146/ANNUREV-MATSCI-080619-022100

S.A. Kube, W. Xing, A. Kalidindi, S. Sohn, A. Datye, D. Amram, C.A. Schuh, J. Schroers, Combinatorial study of thermal stability in ternary nanocrystalline alloys. Acta Mater. 188, 40–48 (2020). https://doi.org/10.1016/j.actamat.2020.01.059

Y.J. Li, A. Kostka, A. Savan, A. Ludwig, Phase decomposition in a nanocrystalline CrCoNi alloy. Scr. Mater. 188, 259–263 (2020). https://doi.org/10.1016/J.SCRIPTAMAT.2020.07.054

A. Inoue, H. Kimura, Fabrications and mechanical properties of bulk amorphous, nanocrystalline, nanoquasicrystalline alloys in aluminum-based system. J. Light Met. 1, 31–41 (2001). https://doi.org/10.1016/S1471-5317(00)00004-3

C.V. Thompson, R. Carel, Texture development in polycrystalline thin films. Mater. Sci. Eng., B 32, 211–219 (1995). https://doi.org/10.1016/0921-5107(95)03011-5

R.K. Gupta, B.S. Murty, N. Birbilis, An Overview of High-Energy Ball Milled Nanocrystalline Aluminum Alloys (Springer, Cham, 2017)

L. Ajdelsztajn, B. Jodoin, G.E. Kim, J.M. Schoenung, Cold spray deposition of nanocrystalline aluminum alloys. Metall. Mater. Trans. A 36, 657–666 (2005)

F. Endres, M. Bukowski, R. Hempelmann, H. Natter, Electrodeposition of nanocrystalline metals and alloys from ionic liquids. Angew. Chem. Int. Ed. 42, 3428–3430 (2003). https://doi.org/10.1002/anie.200350912

C.V. Thompson, Grain growth in thin films. Annu. Rev. Mater. Sci. 20, 245–268 (1990). https://doi.org/10.1063/1.3058054

M. Ohring, Materials Science of Thin Films (Elsevier, Amsterdam, 2001)

H. Okamoto, Al-Ni (Aluminum-Nickel). J. Phase Equilib. 14, 257 (1993)

K.A. Gschneidner, F.W. Calderwood, The Al-Ce (Aluminum-Cerium) System Equilibrium Diagram, n.d.

K. Maung, J.C. Earthman, F.A. Mohamed, Inverse Hall-Petch behavior in diamantane stabilized bulk nanocrystalline aluminum. Acta Mater. 60, 5850–5857 (2012). https://doi.org/10.1016/j.actamat.2012.07.026

Y. Ito, K. Edalati, Z. Horita, High-pressure torsion of aluminum with ultrahigh purity (99.9999%) and occurrence of inverse Hall-Petch relationship. Mater. Sci. Eng. A 679, 428–434 (2017). https://doi.org/10.1016/j.msea.2016.10.066

J. Schioøtz, K.W. Jacobsen, A maximum in the strength of nanocrystalline copper. Science 301, 1357–1359 (2003). https://doi.org/10.1126/SCIENCE.1086636

L. Wang, J. Teng, P. Liu, A. Hirata, E. Ma, Z. Zhang, M. Chen, X. Han, Grain rotation mediated by grain boundary dislocations in nanocrystalline platinum. Nat. Commun. (2014). https://doi.org/10.1038/ncomms5402

Z. Shan, E.A. Stach, J.M.K. Wiezorek, J.A. Knapp, D.M. Follstaedt, S.X. Mao, Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654–657 (2004). https://doi.org/10.1126/science.1098741

T.J. Rupert, J.R. Trelewicz, C.A. Schuh, Grain boundary relaxation strengthening of nanocrystalline Ni–W alloys. J. Mater. Res. 27, 1285–1294 (2012). https://doi.org/10.1557/jmr.2012.55

J. Hu, Y.N. Shi, X. Sauvage, G. Sha, K. Lu, Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 355, 1292–1296 (2017). https://doi.org/10.1126/science.aal5166

O. Renk, V. Maier-Kiener, I. Issa, J.H. Li, D. Kiener, R. Pippan, Anneal hardening and elevated temperature strain rate sensitivity of nanostructured metals: Their relation to intergranular dislocation accommodation. Acta Mater. 165, 409–419 (2019). https://doi.org/10.1016/j.actamat.2018.12.002

X. Huang, N. Hansen, N. Tsuji, Hardening by annealing and softening by deformation in nanostructured metals. Science 312, 249–251 (2006). https://doi.org/10.1126/science.1124268

A. Hasnaoui, H. Van Swygenhoven, P.M. Derlet, On non-equilibrium grain boundaries and their effect on thermal and mechanical behaviour: A molecular dynamics computer simulation. Acta Mater. 50, 3927–3939 (2002). https://doi.org/10.1016/S1359-6454(02)00195-7

N.Q. Vo, J. Schäfer, R.S. Averback, K. Albe, Y. Ashkenazy, P. Bellon, Reaching theoretical strengths in nanocrystalline Cu by grain boundary doping. Scr. Mater. 65, 660–663 (2011). https://doi.org/10.1016/J.SCRIPTAMAT.2011.06.048

Q. Li, J. Wang, H. Wang, X. Zhang, Achieving strong and stable nanocrystalline Al alloys through compositional design. J. Mater. Res. 2021, 1–25 (2021). https://doi.org/10.1557/S43578-021-00363-7

O. Renk, A. Hohenwarter, K. Eder, K.S. Kormout, J.M. Cairney, R. Pippan, Increasing the strength of nanocrystalline steels by annealing: Is segregation necessary? Scr. Mater. 95, 27–30 (2015). https://doi.org/10.1016/J.SCRIPTAMAT.2014.09.023

A.E. Perrin, C.A. Schuh, Stabilized nanocrystalline alloys: The intersection of grain boundary segregation with processing science. Annu. Rev. Mater. Res. 51, 241–268 (2021). https://doi.org/10.1146/ANNUREV-MATSCI-080819-121823

Y.H. Gao, L.F. Cao, J. Kuang, H. Song, G. Liu, J.Y. Zhang, J. Sun, Solute repositioning to tune the multiple microalloying effects in an Al–Cu alloy with minor Sc, Fe and Si addition. Mater. Sci. Eng.: A 803, 140509 (2021). https://doi.org/10.1016/j.msea.2020.140509

D.W. Hoffman, Perspective on stresses in magnetron-sputtered thin films. J. Vac. Sci. Technol., A: Vac. Surf. Films 12, 953 (1998). https://doi.org/10.1116/1.579073

I.G. Mcdonald, W.M. Moehlenkamp, D. Arola, J. Wang, Residual stresses in Cu/Ni multilayer thin films measured using the Sin2ψ method. Exp. Mech. 59, 111–120 (2019). https://doi.org/10.1007/s11340-018-00447-2

S. Suresh, A.E. Giannakopoulos, A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755–5767 (1998). https://doi.org/10.1016/S1359-6454(98)00226-2

T.Y. Tsui, W.C. Oliver, G.M. Pharr, Influences of stress on the measurement of mechanical properties using nanoindentation: Part I. Experimental studies in an aluminum alloy. J. Mater. Res. 11, 752–759 (1996). https://doi.org/10.1557/JMR.1996.0091

A. Bolshakov, W.C. Oliver, G.M. Pharr, Influences of stress on the measurement of mechanical properties using nanoindentation: Part II. Finite element simulations. J. Mater. Res. 11, 760–768 (1996). https://doi.org/10.1557/JMR.1996.0092

K. Hono, Y. Zhang, A.P. Tsai, A. Inoue, T. Sakurai, Solute partitioning in partially crystallized Al-Ni-Ce(-Cu) metallic glasses. Scr. Metall. Mater. 32, 191–196 (1995). https://doi.org/10.1016/S0956-716X(99)80035-1

S. Ruan, C.A. Schuh, Electrodeposited Al–Mn alloys with microcrystalline, nanocrystalline, amorphous and nano-quasicrystalline structures. Acta Mater. 57, 3810–3822 (2009). https://doi.org/10.1016/J.ACTAMAT.2009.04.030

N.A. Belov, E.S. Naumova, Prospects for designing structural cast eutectic alloys on Al-Ce-Ni system base. Metally (Moscow), pp. 146–152 (1996)

H. Wang, Z. Li, Z. Chen, B. Yang, Thermodynamic optimization of the Ni-Al-Ce ternary system. J. Phase Equilib. Diffus. 37, 222–228 (2016). https://doi.org/10.1007/s11669-015-0447-6

A. Hasnaoui, H. Van Swygenhoven, P.M. Derlet, Cooperative processes during plastic deformation in nanocrystalline fcc metals: A molecular dynamics simulation. Phys. Rev. B 66, 184112 (2002). https://doi.org/10.1103/PhysRevB.66.184112

A. Khalajhedayati, T.J. Rupert, Emergence of localized plasticity and failure through shear banding during microcompression of a nanocrystalline alloy. Acta Mater. 65, 326–337 (2014). https://doi.org/10.1016/j.actamat.2013.10.074

T. Brink, K. Albe, From metallic glasses to nanocrystals: Molecular dynamics simulations on the crossover from glass-like to grain-boundary-mediated deformation behaviour. Acta Mater. 156, 205–214 (2018). https://doi.org/10.1016/j.actamat.2018.06.036

R.W. Cheary, A. Coelho, A fundamental parameters approach to X-ray line-profile fitting. J. Appl. Crystallogr. 25, 109–121 (1992). https://doi.org/10.1107/S0021889891010804

A.L. Patterson, The Scherrer formula for X-ray particle size determination. Phys. Rev. 56, 978 (1939). https://doi.org/10.1103/PhysRev.56.978

C. Noyan, T.C. Huang, B.R. York, Residual stress/strain analysis in thin films by X-ray diffraction. Crit. Rev. Solid State Mater. Sci. 20, 125 (1995). https://doi.org/10.1080/10408439508243733

T. Lei, J. Shin, D.S. Gianola, T.J. Rupert, Bulk nanocrystalline Al alloys with hierarchical reinforcement structures via grain boundary segregation and complexion formation. Acta Mater. 221, 117394 (2021). https://doi.org/10.1016/j.actamat.2021.117394

Funding

This material is based upon work supported by the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office Award Number DE‐EE0009114. GHB acknowledges support from the National Science Foundation Graduate Research Fellowship under Grant No. 1650114. This work employed the MRL Shared Experimental Facilities at UC Santa Barbara, which are supported by the MRSEC Program of the NSF under Award No. DMR 1720256; a member of the NSF-funded Materials Research Facilities Network (www.mrfn.org).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shin, J., Wang, F., Balbus, G.H. et al. Optimizing thermal stability and mechanical behavior in segregation-engineered nanocrystalline Al–Ni–Ce alloys: A combinatorial study. Journal of Materials Research 37, 3083–3098 (2022). https://doi.org/10.1557/s43578-022-00715-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00715-x