Abstract

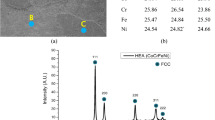

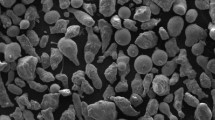

The influence of CoCrFeMnNi high-entropy alloy (HEA) particle addition on the microstructure and mechanical properties of the \({\text{Al}}_{6082}\) the composite was examined. Mechanical alloying was used to develop the CoCrFeMnNi HEA, while stir-squeeze casting assisted with an ultrasonic transducer was used to process the \({\text{Al}}_{6082}\) alloy and \({\text{C}}_{{\mathrm{Al}}_{6082}+{\mathrm{HEA}}_{x\mathrm{wt\%}}}\) composites (where, x = 2, 4, 6, 8). The microstructural and morphological investigation was carried out using XRD, EDS, FESEM, and elemental mapping techniques. At the as-cast condition, the hardness, yield strength, and ultimate tensile strength of the \({\text{C}}_{{\text{Al}}_{6082}+{\text{HEA}}_{8{\text{wt}}\%}}\) composite were increased by 28.57%, 79.46%, and 87.931%, respectively, over monolithic alloy, which was associated with a consistent distribution of HEA particles. Furthermore, it possessed the best tensile strength, yield strength, and fracture strain when compared with \({\text{C}}_{{\text{Al}}_{6082}+{\text{HEA}}}\) composites, indicating a better interaction among HEA particles and Al matrix, and a high dislocation density in the Al matrix.

Graphical abstract

Similar content being viewed by others

Data availability

The processed data will be made available on reasonable request as at this time is part of an ongoing study.

References

T.W. Lu, W.P. Chen, P. Wang, M.D. Mao, Y.X. Liu, Z.Q. Fu, Enhanced mechanical properties and thermo-physical properties of 7075Al hybrid composites reinforced by the mixture of Cr particles and SiCp. J. Alloys Compd. 735, 1137–1144 (2018). https://doi.org/10.1016/j.jallcom.2017.11.227

P. Xie et al., Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 10(1), 1–12 (2019). https://doi.org/10.1038/s41467-019-11848-9

A.S. Sharma, S. Yadav, K. Biswas, B. Basu, High-entropy alloys and metallic nanocomposites: processing challenges, microstructure development and property enhancement. Mater. Sci. Eng. R 131, 1–42 (2018). https://doi.org/10.1016/j.mser.2018.04.003

G.M. Karthik, G.D.J. Ram, R.S. Kottada, Friction deposition of titanium particle reinforced aluminum matrix composites. Mater. Sci. Eng. A 653, 71–83 (2016). https://doi.org/10.1016/j.msea.2015.12.005

S. Scudino, G. Liu, M. Sakaliyska, K.B. Surreddi, J. Eckert, Powder metallurgy of Al-based metal matrix composites reinforced with β-Al3Mg2 intermetallic particles: Analysis and modeling of mechanical properties. Acta Mater. 57(15), 4529–4538 (2009). https://doi.org/10.1016/j.actamat.2009.06.017

S. Selvakumar, I. Dinaharan, R. Palanivel, B. Ganesh Babu, Characterization of molybdenum particles reinforced Al6082 aluminum matrix composites with improved ductility produced using friction stir processing. Mater. Charact. 125, 13–22 (2017). https://doi.org/10.1016/j.matchar.2017.01.016

S. Kumar, V. Balasubramanian, Effect of reinforcement size and volume fraction on the abrasive wear behaviour of AA7075 Al/SiCp P/M composites-a statistical analysis. Tribol. Int. 43(1–2), 414–422 (2010). https://doi.org/10.1016/j.triboint.2009.07.003

M. Acilar, F. Gul, Effect of the applied load, sliding distance and oxidation on the dry sliding wear behaviour of Al-10Si/SiCp composites produced by vacuum infiltration technique. Mater. Des. 25(3), 209–217 (2004). https://doi.org/10.1016/j.matdes.2003.09.015

Y. Xie, X. Meng, R. Zang, Y. Chang, L. Wan, Y. Huang, Deformation-driven modification towards strength-ductility enhancement in Al–Li–Mg–Zn–Cu lightweight high-entropy alloys. Mater. Sci. Eng. A 830, 142332 (2022). https://doi.org/10.1016/j.msea.2021.142332

J. Li, X. Meng, L. Wan, Y. Huang, Welding of high entropy alloys: progresses, challenges and perspectives. J. Manuf. Process. 68, 293–331 (2021). https://doi.org/10.1016/j.jmapro.2021.05.042

J.W. Yeh et al., Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004). https://doi.org/10.1002/adem.200300567

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377(1–2), 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

E.J. Pickering, N.G. Jones, High-entropy alloys: a critical assessment of their founding principles and future prospects. Int. Mater. Rev. 61(3), 183–202 (2016). https://doi.org/10.1080/09506608.2016.1180020

J.W. Yeh, Recent progress in high-entropy alloys. Ann. Chim. Sci. des Mater. 31(6), 633–648 (2006). https://doi.org/10.3166/acsm.31.633-648

A. Arab, Y. Guo, Q. Zhou, P. Chen, Fabrication of nanocrystalline AlCoCrFeNi high entropy alloy through shock consolidation and mechanical alloying. Entropy 21(9), 880 (2019). https://doi.org/10.3390/e21090880

Y. Wu, P.K. Liaw, Y. Zhang, Preparation of bulk tizrnbmov and nbtialtav high-entropy alloys by powder sintering. Metals (Basel) 11(11), 1–12 (2021). https://doi.org/10.3390/met11111748

A. Parakh, M. Vaidya, N. Kumar, R. Chetty, B.S. Murty, Effect of crystal structure and grain size on corrosion properties of AlCoCrFeNi high entropy alloy. J. Alloys Compd. 863, 158056 (2021). https://doi.org/10.1016/j.jallcom.2020.158056

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, P.K. Liaw, Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 118, 100777 (2021). https://doi.org/10.1016/j.pmatsci.2021.100777

E. Abbasi, K. Dehghani, Phase prediction and microstructure of centrifugally cast non-equiatomic Co-Cr-Fe-Mn-Ni(Nb, C) high entropy alloys. J. Alloys Compd. 783, 292–299 (2019). https://doi.org/10.1016/j.jallcom.2018.12.329

B. Gwalani et al., Compositionally graded high entropy alloy with a strong front and ductile back. Mater. Today Commun. 20, 100602 (2019). https://doi.org/10.1016/j.mtcomm.2019.100602

L. Tian, M. Fu, W. Xiong, Microstructural evolution of AlCoCrFeNiSi high-entropy alloy powder during mechanical alloying and its coating performance. Materials (2018). https://doi.org/10.3390/ma11020320

A. Kumar, A. Singh, A. Suhane, Mechanically alloyed high entropy alloys: existing challenges and opportunities. J. Mater. Res. Technol. 17, 2431–2456 (2022). https://doi.org/10.1016/j.jmrt.2022.01.141

K. Praveen Kumar, M. Gopi Krishna, J. Babu Rao, N.R.M.R. Bhargava, Fabrication and characterization of 2024 aluminium—high entropy alloy composites. J. Alloys Compd. 640, 421–427 (2015). https://doi.org/10.1016/j.jallcom.2015.03.093

Z.W. Wang, Y.B. Yuan, R.X. Zheng, K. Ameyama, C.L. Ma, Microstructures and mechanical properties of extruded 2024 aluminum alloy reinforced by FeNiCrCoAl3 particles. Trans. Nonferrous Met. Soc. China 24(7), 2366–2373 (2014). https://doi.org/10.1016/S1003-6326(14)63358-6

R.K. Prabakaran, A.N. Sait, V. Senthilkumar, Synthesis and characteristization of high entropy alloy (crmnfenicu) reinforced AA6061 aluminium matrix composite. Mech. Mech. Eng. 21(2), 415–424 (2017)

J. Li et al., Friction stir processing of high-entropy alloy reinforced aluminum matrix composites for mechanical properties enhancement. Mater. Sci. Eng. A 792, 139755 (2020). https://doi.org/10.1016/j.msea.2020.139755

E. Ananiadis, K.T. Argyris, T.E. Matikas, A.K. Sfikas, A.E. Karantzalis, Microstructure and corrosion performance of aluminium matrix composites reinforced with refractory high-entropy alloy particulates. Appl. Sci. 11(3), 1–12 (2021). https://doi.org/10.3390/app11031300

Y. Liu, J. Chen, X. Wang, T. Guo, J. Liu, Significantly improving strength and plasticity of Al-based composites by in-situ formed AlCoCrFeNi core–shell structure. J. Mater. Res. Technol. 15, 4117–4129 (2021). https://doi.org/10.1016/j.jmrt.2021.10.016

Y.L. Chen, Y.H. Hu, C.A. Hsieh, J.W. Yeh, S.K. Chen, Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system. J. Alloys Compd. 481(1–2), 768–775 (2009). https://doi.org/10.1016/j.jallcom.2009.03.087

T. Lu et al., The influence of nanocrystalline CoNiFeAl0.4Ti0.6Cr0.5 high-entropy alloy particles addition on microstructure and mechanical properties of SiCp/7075Al composites. Mater. Sci. Eng. A 726, 126–136 (2018). https://doi.org/10.1016/j.msea.2018.04.080

X. Jiang, M. Galano, F. Audebert, Extrusion textures in Al, 6061 alloy and 6061/SiCp nanocomposites. Mater. Charact. 88, 111–118 (2014). https://doi.org/10.1016/j.matchar.2013.11.009

K. Huang, K. Marthinsen, Q. Zhao, R.E. Logé, The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials. Prog. Mater. Sci. 92, 284–359 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.004

J. Liu et al., Improved structural homogeneity and mechanical properties of nanoparticles reinforced Al composites after orthogonal thermomechanical processes. J. Alloys Compd. 767, 293–301 (2018). https://doi.org/10.1016/j.jallcom.2018.07.083

J. Liu et al., Simultaneously increasing strength and ductility of nanoparticles reinforced Al composites via accumulative orthogonal extrusion process. Mater. Res. Lett. (2018). https://doi.org/10.1080/21663831.2018.1471421

Y. Sun, L. Fu, Z. Fu, A. Shan, E.J. Lavernia, Enhanced thermal stability and ductility in a nanostructured Ni-based alloy. Scr. Mater. 141, 1–5 (2017). https://doi.org/10.1016/j.scriptamat.2017.07.013

X. Wu et al., Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. (2015). https://doi.org/10.1073/pnas.1517193112

Z. Wang et al., Tensile properties of Al–12Si matrix composites reinforced with Ti–Al-based particles. J. Alloys Compd. 630, 256–259 (2015). https://doi.org/10.1016/j.jallcom.2014.12.254

Y. Zhao, X. Ma, H. Chen, X. Zhao, X. Liu, Preferred orientation and interfacial structure in extruded nano-Al 3 BC/6061 Al. Mater. Des. 131, 23–31 (2017). https://doi.org/10.1016/j.matdes.2017.05.088

A.R. Miedema, On the heat of formation of solid alloys. II. J. Less-Common Met. 46(1), 67–83 (1976). https://doi.org/10.1016/0022-5088(76)90180-6

X. Yang, Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132(2–3), 233–238 (2012). https://doi.org/10.1016/j.matchemphys.2011.11.021

Y. Song, D. Kim, S. Nam, K.A. Lee, H. Choi, Effect of milling duration on oxide-formation behavior of oxide-dispersion-strengthened high-entropy alloys. Arch. Metall. Mater. 66(3), 735–740 (2021). https://doi.org/10.24425/amm.2021.136371

A. Fourmont, S. Le Gallet, O. Politano, C. Desgranges, F. Baras, Effects of planetary ball milling on AlCoCrFeNi high entropy alloys prepared by Spark Plasma Sintering: experiments and molecular dynamics study. J. Alloys Compd. 820, 153448 (2020). https://doi.org/10.1016/j.jallcom.2019.153448

W.W. Zhang et al., A novel high-strength Al-based nanocomposite reinforced with Ti-based metallic glass nanoparticles produced by powder metallurgy. Mater. Sci. Eng. A 734, 34–41 (2018). https://doi.org/10.1016/j.msea.2018.07.082

R.N. Shahid, S. Scudino, Strengthening of Al-Fe3Al composites by the generation of harmonic structures. Sci. Rep. 8(1), 1–12 (2018). https://doi.org/10.1038/s41598-018-24824-y

H. Yang, T.D. Topping, K. Wehage, L. Jiang, E.J. Lavernia, J.M. Schoenung, Tensile behavior and strengthening mechanisms in a submicron B4C-reinforced Al trimodal composite. Mater. Sci. Eng. A 616, 35–43 (2014). https://doi.org/10.1016/j.msea.2014.07.079

M. Yang, D. Yan, F. Yuan, P. Jiang, E. Ma, X. Wu, Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength. Proc. Natl. Acad. Sci. USA 115(28), 7224–7229 (2018). https://doi.org/10.1073/pnas.1807817115

N. Chawla, J.J. Williams, R. Saha, Mechanical behavior and microstructure characterization of sinter-forged SiC particle reinforced aluminum matrix composites. J. Light Met. 2(4), 215–227 (2002). https://doi.org/10.1016/S1471-5317(03)00005-1

G.E. Dieter, Mechanical metallurgy. Mech. Metall. (2011). https://doi.org/10.5962/bhl.title.35895

K.B. Nie, X.J. Wang, K. Wu, X.S. Hu, M.Y. Zheng, Development of SiCp/AZ91 magnesium matrix nanocomposites using ultrasonic vibration. Mater. Sci. Eng. A 540, 123–129 (2012). https://doi.org/10.1016/j.msea.2012.01.112

H. Yang, L. Jiang, M. Balog, P. Krizik, J.M. Schoenung, Reinforcement size dependence of load bearing capacity in ultrafine-grained metal matrix composites. Metall. Mater. Trans. A 48(9), 4385–4392 (2017). https://doi.org/10.1007/s11661-017-4186-7

L. Zhao, H. Lu, Z. Gao, Microstructure and mechanical properties of Al/graphene composite produced by high-pressure torsion. Adv. Eng. Mater. 17(7), 976–981 (2015). https://doi.org/10.1002/adem.201400375

S.F. Hassan, M. Gupta, Effect of particulate size of Al2O3 reinforcement on microstructure and mechanical behavior of solidification processed elemental Mg. J. Alloys Compd. 419(1–2), 84–90 (2006). https://doi.org/10.1016/j.jallcom.2005.10.005

L. Jiang et al., Toughening of aluminum matrix nanocomposites via spatial arrays of boron carbide spherical nanoparticles. Acta Mater. 103, 128–140 (2016). https://doi.org/10.1016/j.actamat.2015.09.057

Z. Zhang et al., Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles. Scr. Mater. 65(8), 652–655 (2011). https://doi.org/10.1016/j.scriptamat.2011.06.037

X. Du, T. Gao, Z. Qian, Y. Wu, X. Liu, The in-situ synthesis and strengthening mechanism of the multi-scale SiC particles in Al-Si-C alloys. J. Alloys Compd. 750, 935–944 (2018). https://doi.org/10.1016/j.jallcom.2018.04.006

W. Jiang, J. Zhu, G. Li, F. Guan, Y. Yu, Z. Fan, Enhanced mechanical properties of 6082 aluminum alloy via SiC addition combined with squeeze casting. J. Mater. Sci. Technol. 88, 119–131 (2021). https://doi.org/10.1016/j.jmst.2021.01.077

K. Ravi Kumar, T. Pridhar, V.S. Sree Balaji, Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash(CSA) reinforced aluminium (Al 6082) matrix hybrid composite. J. Alloys Compd. 765, 171–179 (2018). https://doi.org/10.1016/j.jallcom.2018.06.177

J. Zhu, W. Jiang, G. Li, F. Guan, Y. Yu, Z. Fan, Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J. Mater. Process. Technol. 283, 116699 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116699

K. Ravikumar, K. Kiran, V.S. Sreebalaji, Characterization of mechanical properties of aluminium/tungsten carbide composites. Meas. J. Int. Meas. Confed. 102, 142–149 (2017). https://doi.org/10.1016/j.measurement.2017.01.045

P. Roy, S. Singh, K. Pal, Enhancement of mechanical and tribological properties of SiC- and CB-reinforced aluminium 7075 hybrid composites through friction stir processing. Adv. Compos. Mater. 28(sup1), 1–18 (2019). https://doi.org/10.1080/09243046.2017.1405596

Acknowledgments

We author sincerely acknowledge the support provided by the Maulana Azad National Institute of Technology, Bhopal, and extend their gratitude to the Materials Research center, Malaviya National Institute of Technology Jaipur for their Key support.

Funding

No Funding is available.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Singh, A. & Suhane, A. Synthesis and characterization of a novel CoCrFeMnNi high-entropy alloy-reinforced AA6082 composite. Journal of Materials Research 37, 2961–2978 (2022). https://doi.org/10.1557/s43578-022-00701-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00701-3