Abstract

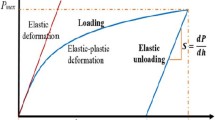

Nanoindentation is an experimental technique used for the determination of Young modulus. The commonly used Oliver-Pharr analysis based on the assumption of the equivalence of indentation curves obtained with a Berkovich and a conical indenter is employed. Nevertheless, a break-down of this equivalence in projected area between the pyramidal and conical geometry was found. This discrepancy leads to an overestimation of Young modulus and needs to be corrected with coefficient \(\beta\). It corrects the difference between Young modulus from the conical and the Berkovich indentation but cannot correct the indentation curves. This paper aims at the FEM study of modelling of the nanoindentation test, the influence of the Oliver-Pharr analysis assumptions, the comparison and unification of the different values of \(\beta\) for the Berkovich and the conical indentation with a rigid and a diamond indenter, the correction of the indentation curves, and the explanation of the differences between the FEM calculated and experimentally measured indentation curves.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

S.W. Moore, M.T. Manzari, Y.-L. Shen, Int J Smart Nano Mater 1, 2 (2010). https://doi.org/10.1080/19475411003589889

A.M.S. Dias, G.C.D. Godoy, Mater. Sci. Forum (2010). https://doi.org/10.4028/www.scientific.net/MSF.636-637.1186

K.-D. Bouzakis, N. Michailidis, S. Hadjiyiannis, G. Skordaris, G. Erkens, Mater. Charact. 49, 2 (2002). https://doi.org/10.1016/S1044-5803(02)00361-3

T. Chudoba, P. Schwaller, R. Rabe, J.-M. Breguet, J. Michler, Philos. Mag. 86, 33–35 (2006). https://doi.org/10.1080/14786430600746424

Y.J. Park, G.M. Pharr, Thin Solid Films (2004). https://doi.org/10.1016/S0040-6090(03)01102-7

S. Pathak, S.R. Kalidindi, Mater. Sci. Eng. R Rep. (2015). https://doi.org/10.1016/j.mser.2015.02.001

A.C. Fisher-Cripps, Nanoindentation (2004). https://doi.org/10.1007/978-1-4757-5943-3_2

Z. Shi, X. Feng, Y. Huang, J. Xiao, K.C. Hwang, Int. J. Plast. 26, 1 (2010). https://doi.org/10.1016/j.ijplas.2009.06.008

W.C. Oliver, G.M. Pharr, J. Mater. Res. 7, 6 (1992). https://doi.org/10.1557/JMR.1992.1564

S. Shim, W.C. Oliver, G.M. Pharr, Int. J. Surf. Sci. Eng. 1, 2–3 (2007). https://doi.org/10.1504/IJSURFSE.2007.015028

W.C. Oliver, G.M. Pharr, J. Mater. Res. 19, 1 (2004). https://doi.org/10.1557/jmr.2004.19.1.3

D. Torres-Torres, J. Muñoz-Saldaña, L.A. Gutierrez-Ladron-de Guevara, A. Hurtado-Macías, M.V. Swain, Model Simul. Mat. Sci. Eng. 18, 7 (2010). https://doi.org/10.1088/0965-0393/18/7/075006

C. Shi, H. Zhao, H. Huang, L. Xu, L. Ren, M. Bai, J. Li, X. Hu, Mater. Trans. 54(6), 958–963 (2013). https://doi.org/10.2320/matertrans.M2012400

J. Kovář, V. Fuis, J. Tomáštík, Acta Polytech. CTU Proc. (2020). https://doi.org/10.14311/APP.2020.27.0131

J. Krier, J. Breuils, L. Jacomine, H. Pelletier, J. Mater. Res. 27, 1 (2012). https://doi.org/10.1557/jmr.2011.387

M. Jamal, M.N. Morgan, Inventions 4, 3 (2019). https://doi.org/10.3390/inventions4030040

G.M. Pharr, A. Bolshakov, J. Mater. Res. 17, 10 (2002). https://doi.org/10.1557/JMR.2002.0386

K.R. Gadelrab, M. Chiesa, F.A. Bonilla, J. Mater. Res. 27, 1 (2012). https://doi.org/10.1557/jmr.2011.229

N.A. Sakharova, J.V. Fernandes, J.M. Antunes, M.C. Oliveira, Int. J. Solids Struct. 46, 5 (2009). https://doi.org/10.1016/j.ijsolstr.2008.10.032

T. Andriollo, J. Thorborg, J. Hattel, Model. Simulat. Mater. Sci. Eng. 25, 4 (2017). https://doi.org/10.1088/1361-651X/aa6831

J.C. Hay, A. Bolshakov, G.M. Pharr, J. Mater. Res. 14, 6 (1999). https://doi.org/10.1557/JMR.1999.0306

Y. Tanaka, Y. Seino, K. Hattori, ACTA IMEKO 9(5), 265–269 (2020). https://doi.org/10.21014/acta_imeko.v9i5.982

T. Chudoba, N.M. Jennett, J. Phys. D Appl. Phys. 41, 21 (2008). https://doi.org/10.1088/0022-3727/41/21/215407

R.B. King, Int. J. Solids. Struct. 23, 12 (1987). https://doi.org/10.1016/0020-7683(87)90116-8

J.J. Vlassak, W.D. Nix, J. Mech. Phys. Solids 42, 8 (1994). https://doi.org/10.1016/0022-5096(94)90033-7

I.N. Sneddon, Int. J. Eng. Sci. 3, 1 (1965). https://doi.org/10.1016/0022-5096(94)90033-710.1016/0020-7225(65)90019-4

P.-L. Larsson, A.E. Giannakopoulos, E. Söderlund, D.J. Rowcliffe, R. Vestergaard, Int. J. Solids Struct. 33, 2 (1996). https://doi.org/10.1016/0020-7683(95)00033-7

K.R. Gadelrab, F.A. Bonilla, M. Chiesa, J. Non-Cryst. Solids 358(2), 392–398 (2012). https://doi.org/10.1016/j.jnoncrysol.2011.10.011

Load controlled vs displacement controlled models – which one to use in FEA? (2021). https://featips.com/

B. Beake, A. Harris, T. Liskiewicz, Mater. Charact. 1, 89 (2015). https://doi.org/10.1201/b19177-2

Technical Glass Products, Inc. (TGP) (2021). https://technicalglass.com/technical_properties/

Atlas of stress-strain curves, 2nd Edition (ASM International, Materials Park OH, USA, 2002).

J. Kovář, V. Fuis, R. Čtvrtlík, Eng. Mech. (Brno, 2020). https://doi.org/10.21495/5896-3-298

Acknowledgments

This study was realized with the support by the grant FSI-S-20-6164 and with the institutional support RVO: 61388998. The authors also gratefully acknowledge the support by the Operational Program Research, Development and Education, projects No. CZ.02.1.01/0.0/0.0/17_049/0008422 and No. CZ.02.1.01/0.0/0.0/16_019/0000754 of the Ministry of Education, Youth and Sports of the Czech Republic. RČ and JT also thank the project No. TN01000038 of the Technology Agency of the Czech Republic for support of their workplace.

Funding

This study was realized with the support by the grant FSI-S-20–6164 and with the institutional support RVO: 61388998. The authors also gratefully acknowledge the support by the Operational Program Research, Development and Education, Projects No. CZ.02.1.01/0.0/0.0/17_049/0008422 and No. CZ.02.1.01/0.0/0.0/16_019/0000754 of the Ministry of Education, Youth and Sports of the Czech Republic. RČ and JT also thank the Project No. TN01000038 of the Technology Agency of the Czech Republic for support of their workplace.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study and writing the paper. The FEM calculations and calculations of the correction factors were done by JK and VF. The experimental analysis and evaluation of the results of nanoindentation were done by RČ and JT. The concept of the paper was designed by JK, VF and RČ. The first draft of the manuscript was written by JK and all authors commented, read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kovář, J., Fuis, V., Čtvrtlík, R. et al. The discrepancy between the indentation curves obtained by the finite element method calculation with a Berkovich and a conical indenter. Journal of Materials Research 37, 1750–1761 (2022). https://doi.org/10.1557/s43578-022-00574-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00574-6