Abstract

Significant attention in the literature is directed toward the development of scaling relations that relate the properties of nanoporous metals to bulk materials in order to help in their design. Although nanoporous gold has been under extensive study to develop the proper scaling relations, the literature still lacks a specific model that predicts its properties based on a combination of surface parameters, ligament size, and relative density. This work is part of the ongoing trials to introduce such scaling relations. Therefore, utilizing literature-reported results, the authors are proposing scaling relations that account for the coupling effect of surface area to solid volume ratio, ligament size, and relative density to predict the elastic modulus, yield stress, and ultimate stress under uniaxial loading. Moreover, a comparison between the proposed model and existing scaling laws in the literature is presented.

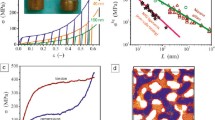

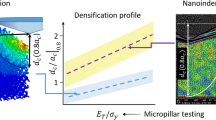

Graphic abstract

Similar content being viewed by others

References

A.M. Hodge, J. Biener, J.R. Hayes, P.M. Bythrow, C.A. Volkert, A.V. Hamza, Scaling equation for yield strength of nanoporous open-cell foams. Acta Mater. 55, 1343–1349 (2007). https://doi.org/10.1016/j.actamat.2006.09.038

G. Pia, M. Carta, F. Delogu, Nanoporous Au foams: variation of effective Young’s modulus with ligament size. Scr. Mater. 144, 22–26 (2018). https://doi.org/10.1016/j.scriptamat.2017.09.038

N.J. Briot, T. Kennerknecht, C. Eberl, T.J. Balk, Mechanical properties of bulk single crystalline nanoporous gold investigated by millimetre-scale tension and compression testing. Philos. Magn. 94, 847–866 (2014). https://doi.org/10.1080/14786435.2013.868944

L.Z. Liu, H.J. Jin, Scaling equation for the elastic modulus of nanoporous gold with “fixed” network connectivity. Appl. Phys. Lett. (2017). https://doi.org/10.1063/1.4984108

H.J. Jin, L. Kurmanaeva, J. Schmauch, H. Rösner, Y. Ivanisenko, J. Weissmüller, Deforming nanoporous metal: Role of lattice coherency. Acta Mater. 57, 2665–2672 (2009). https://doi.org/10.1016/j.actamat.2009.02.017

J.F. Rodriguez-Nieva, C.J. Ruestes, Y. Tang, E.M. Bringa, Atomistic simulation of the mechanical properties of nanoporous gold. Acta Mater. 80, 67–76 (2014). https://doi.org/10.1016/j.actamat.2014.07.051

C.J. Ruestes, D. Farkas, A. Caro, E.M. Bringa, Hardening under compression in Au foams. Acta Mater. 108, 1–7 (2016). https://doi.org/10.1016/j.actamat.2016.02.030

B.N.D. Ngô, B. Roschning, K. Albe, J. Weissmüller, J. Markmann, On the origin of the anomalous compliance of dealloying-derived nanoporous gold. Scr. Mater. 130, 74–77 (2017). https://doi.org/10.1016/j.scriptamat.2016.11.006

C.J. Ruestes, D. Schwen, E.N. Millán, E. Aparicio, E.M. Bringa, Mechanical properties of Au foams under nanoindentation. Comput. Mater. Sci. 147, 154–167 (2018). https://doi.org/10.1016/j.commatsci.2018.02.019

D. Farkas, A. Caro, E. Bringa, D. Crowson, Mechanical response of nanoporous gold. Acta Mater. 61, 3249–3256 (2013). https://doi.org/10.1016/j.actamat.2013.02.013

N. Huber, R.N. Viswanath, N. Mameka, J. Markmann, J. Weißmüller, Scaling laws of nanoporous metals under uniaxial compression. Acta Mater. 67, 252–265 (2014). https://doi.org/10.1016/j.actamat.2013.12.003

B.N.D. Ngô, A. Stukowski, N. Mameka, J. Markmann, K. Albe, J. Weissmüller, Anomalous compliance and early yielding of nanoporous gold. Acta Mater. 93, 144–155 (2015). https://doi.org/10.1016/j.actamat.2015.04.021

M. Bürckert, N.J. Briot, T.J. Balk, Uniaxial compression testing of bulk nanoporous gold. Philos. Magn. 97, 1157–1178 (2017). https://doi.org/10.1080/14786435.2017.1292060

D. Lee, X. Wei, M. Zhao, X. Chen, S.C. Jun, J. Hone, J.W. Kysar, Plastic deformation in nanoscale gold single crystals and open-celled nanoporous gold. Model. Simul. Mater. Sci. Eng. (2007). https://doi.org/10.1088/0965-0393/15/1/S15

B. Roschning, N. Huber, Scaling laws of nanoporous gold under uniaxial compression: effects of structural disorder on the solid fraction, elastic Poisson’s ratio, Young’s modulus and yield strength. J. Mech. Phys. Solids. 92, 55–71 (2016). https://doi.org/10.1016/j.jmps.2016.02.018

L.J. Gibson, M.F. Ashby, Cellular solids. MRS Bull. 28, 429–450 (1997). https://doi.org/10.1557/mrs2003.79

L.Z. Liu, X.L. Ye, H.J. Jin, Interpreting anomalous low-strength and low-stiffness of nanoporous gold: quantification of network connectivity. Acta Mater. 118, 77–87 (2016). https://doi.org/10.1016/j.actamat.2016.07.033

C.A. Volkert, E.T. Lilleodden, D. Kramer, J. Weissmüller, Approaching the theoretical strength in nanoporous Au. Appl. Phys. Lett. 89, 10–13 (2006). https://doi.org/10.1063/1.2240109

N. Beets, D. Farkas, S. Corcoran, Deformation mechanisms and scaling relations in the mechanical response of nano-porous Au. Acta Mater. 165, 626–637 (2019). https://doi.org/10.1016/j.actamat.2018.12.006

K.R. Mangipudi, E. Epler, C.A. Volkert, Topology-dependent scaling laws for the stiffness and strength of nanoporous gold. Acta Mater. 119, 115–122 (2016). https://doi.org/10.1016/j.actamat.2016.08.012

K. Hu, M. Ziehmer, K. Wang, E.T. Lilleodden, Nanoporous gold: 3D structural analyses of representative volumes and their implications on scaling relations of mechanical behaviour. Philos. Mag. 96, 3322–3335 (2016). https://doi.org/10.1080/14786435.2016.1222087

R. Dou, B. Derby, Strain gradients and the strength of nanoporous gold. J. Mater. Res. 25, 746–753 (2010). https://doi.org/10.1557/JMR.2010.0099

J. Biener, A.M. Hodge, A.V. Hamza, L.M. Hsiung, J.H. Satcher, Nanoporous Au: a high yield strength material. J. Appl. Phys. 97, 1–5 (2005). https://doi.org/10.1063/1.1832742

J. Biener, A.M. Hodge, A.V. Hamza, Microscopic failure behavior of nanoporous gold. Appl. Phys. Lett. 87, 1–3 (2005). https://doi.org/10.1063/1.2051791

N.J. Briot, T.J. Balk, Developing scaling relations for the yield strength of nanoporous gold. Philos. Mag. 95, 2955–2973 (2015). https://doi.org/10.1080/14786435.2015.1078512

N. Mameka, K. Wang, J. Markmann, E.T. Lilleodden, J. Weissmüller, Nanoporous gold—testing macro-scale samples to probe small-scale mechanical behavior. Mater. Res. Lett. 4, 27–36 (2016). https://doi.org/10.1080/21663831.2015.1094679

N. Badwe, X. Chen, K. Sieradzki, Mechanical properties of nanoporous gold in tension. Acta Mater. 129, 251–258 (2017). https://doi.org/10.1016/j.actamat.2017.02.040

A. Giri, J. Tao, L. Wang, M. Kirca, A.C. To, Compressive behavior and deformation mechanism of nanoporous open-cell foam with ultrathin ligaments. J. Nanomech. Micromech. 4, A4013012 (2013). https://doi.org/10.1061/(asce)nm.2153-5477.0000079

M.H. Saffarini, G.Z. Voyiadjis, C.J. Ruestes, M. Yaghoobi, Ligament size dependency of strain hardening and ductility in nanoporous gold. Comput. Mater. Sci. 186, 109920 (2020). https://doi.org/10.1016/j.commatsci.2020.109920

J. Biener, A.M. Hodge, J.R. Hayes, C.A. Volkert, L.A. Zepeda-Ruiz, A.V. Hamza, F.F. Abraham, Size effects on the mechanical behavior of nanoporous Au. Nano Lett. 6, 2379–2382 (2006). https://doi.org/10.1021/nl061978i

X.Y. Sun, G.K. Xu, X. Li, X.Q. Feng, H. Gao, Mechanical properties and scaling laws of nanoporous gold. J. Appl. Phys. (2013). https://doi.org/10.1063/1.4774246

N. Mameka, J. Markmann, J. Weissmüller, On the impact of capillarity for strength at the nanoscale. Nat. Commun. 8, 1–9 (2017). https://doi.org/10.1038/s41467-017-01434-2

R. Xia, X.Q. Feng, G.F. Wang, Effective elastic properties of nanoporous materials with hierarchical structure. Acta Mater. 59, 6801–6808 (2011). https://doi.org/10.1016/j.actamat.2011.07.039

A. Stukowski, Computational analysis methods in atomistic modeling of crystals. JOM 66, 399–407 (2014). https://doi.org/10.1007/s11837-013-0827-5

N. Mameka, J. Markmann, H.J. Jin, J. Weissmüller, Electrical stiffness modulation - confirming the impact of surface excess elasticity on the mechanics of nanomaterials. Acta Mater. 76, 272–280 (2014). https://doi.org/10.1016/j.actamat.2014.04.067

R. Namakian, G.Z. Voyiadjis, P. Kwaśniak, On the slip and twinning mechanisms on first order pyramidal plane of magnesium: molecular dynamics simulations and first principal studies. Mater. Des. 191, 108648 (2020). https://doi.org/10.1016/j.matdes.2020.108648

J. Lao, M. Naghdi Tam, D. Pinisetty, N. Gupta, Molecular dynamics simulation of FCC metallic nanowires: a review. JOM 65, 175–184 (2013). https://doi.org/10.1007/s11837-012-0465-3

W. Liang, M. Zhou, Discovery, characterization and modelling of novel shape memory behaviour of fcc metal nanowires. Philos. Mag. 87, 2191–2220 (2007). https://doi.org/10.1080/14786430701280943

D. Huang, Q. Zhang, P. Qiao, Molecular dynamics evaluation of strain rate and size effects on mechanical properties of FCC nickel nanowires. Comput. Mater. Sci. 50, 903–910 (2011). https://doi.org/10.1016/j.commatsci.2010.10.028

Y.H. Wen, Z.Z. Zhu, R.Z. Zhu, Molecular dynamics study of the mechanical behavior of nickel nanowire: strain rate effects. Comput. Mater. Sci. 41, 553–560 (2008). https://doi.org/10.1016/j.commatsci.2007.05.012

Z. Yang, Z. Lu, Y.P. Zhao, Atomistic simulation on size-dependent yield strength and defects evolution of metal nanowires. Comput. Mater. Sci. 46, 142–150 (2009). https://doi.org/10.1016/j.commatsci.2009.02.015

H. Ikeda, Y. Qi, T. Çagin, K. Samwer, W.L. Johnson, W.A. Goddard, Strain rate induced amorphization in metallic nanowires. Phys. Rev. Lett. 82, 2900–2903 (1999). https://doi.org/10.1103/PhysRevLett.82.2900

H.A. Wu, A.K. Soh, X.X. Wang, Z.H. Sun, Strength and Fracture of Single Crystal Metal Nanowire (Trans Tech Publications Ltd, Baech, 2004), pp. 33–38

R. Xia, C. Xu, W. Wu, X. Li, X.Q. Feng, Y. Ding, Microtensile tests of mechanical properties of nanoporous Au thin films. J. Mater. Sci. 44, 4728–4733 (2009). https://doi.org/10.1007/s10853-009-3731-1

L. Lührs, C. Soyarslan, J. Markmann, S. Bargmann, J. Weissmüller, Elastic and plastic Poisson’s ratios of nanoporous gold. Scr. Mater. 110, 65–69 (2016). https://doi.org/10.1016/j.scriptamat.2015.08.002

V.S. Deshpande, N.A. Fleck, Isotropic constitutive models for metallic foams, n.d. www.elsevier.com/locate/jmps (accessed August 13, 2020).

G.Z. Voyiadjis, M. Yaghoobi, Size Effects in Plasticity: From Macro to Nano, 1st edn. (Elsevier, Amsterdam, 2019).

G.Z. Voyiadjis, R.K.A. Al-Rub, Gradient plasticity theory with a variable length scale parameter. Int. J. Solids Struct. 42, 3998–4029 (2005). https://doi.org/10.1016/j.ijsolstr.2004.12.010

G.Z. Voyiadjis, D. Faghihi, Gradient plasticity for thermo-mechanical processes in metals with length and time scales. Philos. Mag. 93, 1013–1053 (2013). https://doi.org/10.1080/14786435.2012.740576

G.Z. Voyiadjis, B. Deliktas, Modeling of Strengthening and Softening in Inelastic Nanocrystalline Materials with Reference to the Triple Junction and Grain Boundaries Using Strain Gradient Plasticity (Springer, New York, 2010), pp. 3–26

K.R. Mangipudi, E. Epler, C.A. Volkert, On the multiaxial yielding and hardness to yield stress relation of nanoporous gold. Scr. Mater. 146, 150–153 (2018). https://doi.org/10.1016/j.scriptamat.2017.11.033

Y.C. Kim, E.J. Gwak, S. Min Ahn, J. Il Jang, H.N. Han, J.Y. Kim, Indentation size effect in nanoporous gold. Acta Mater. 138, 52–60 (2017). https://doi.org/10.1016/j.actamat.2017.07.040

L. Lührs, B. Zandersons, N. Huber, J. Weissmüller, Plastic Poisson’s ratio of nanoporous metals: a macroscopic signature of tension-compression asymmetry at the nanoscale. Nano Lett. 17, 6258–6266 (2017). https://doi.org/10.1021/acs.nanolett.7b02950

A. Leitner, V. Maier-Kiener, J. Jeong, M.D. Abad, P. Hosemann, S.H. Oh, D. Kiener, Interface dominated mechanical properties of ultra-fine grained and nanoporous Au at elevated temperatures. Acta Mater. 121, 104–116 (2016). https://doi.org/10.1016/j.actamat.2016.08.071

Acknowledgments

G.Z.V. acknowledges the financial support provided by a grant from the National Science Foundation EPSCoR CIMM (Grant Number #OIA-1541079). C.J.R. thanks SiiP-UNCuyo Grant and ANPCyT PICT funding.

Author information

Authors and Affiliations

Contributions

MHS: Conceptualization, Methodology, Software, Validation, Formal analysis, Investigation, Data Curation, Writing—Original Draft, Writing—Review & Editing, and Visualization. GZV: Resources, Writing—Review & Editing, Visualization, Supervision, Project administration, and Funding acquisition. CJR: Validation, Formal analysis, Writing—Review & Editing, and Visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Saffarini, M.H., Voyiadjis, G.Z. & Ruestes, C.J. Scaling laws for nanoporous metals under uniaxial loading. Journal of Materials Research 36, 2729–2741 (2021). https://doi.org/10.1557/s43578-021-00161-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00161-1