Abstract

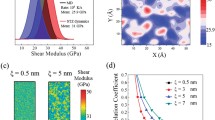

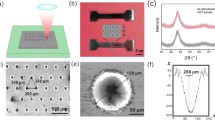

Monolithic metallic glass is a quasi-brittle material with little plasticity on a continuum scale, but tremendous local plasticity in nano- and micron scales. One way to enhance the macroscopic plasticity and toughness is to make composites with inclusions that can alter the local shear behavior. By far, however, the attempt still faces tremendous challenges. Here, we propose a new concept by introducing microstructures into the structureless glasses by spatially patterning the heterogeneities. One case study shown here is to form the stochastically distributed glass domains or “grains” and their boundaries that have different kinds of heterogeneities. We demonstrate that the granular metallic glass (GMG) can be toughened and even “hardened” by tuning the grain-boundary width, amount of free volumes, and grain size. The hardening mechanisms in the emerging GMG are intricately related to how shear banding is blocked or promoted by the spatially patterned heterogeneity if proper length scales of the heterogeneities are organized and function synchronously.

Impact statement

Different from crystalline materials, glassy materials do not have ordered atomic structures. As a result, they all appear brittle macroscopically, which includes metallic glasses despite the well-known metallic bonding that supposedly gives rise to ductility. As a twist, different from other types of glasses such as oxide glasses, metallic glasses possess tremendous ductility in nanometer and micrometer scales. Therefore, how to manage the microscopic ductility and extend it to macroscopic scale becomes one of the most challenging engineering as well as scientific problems facing materials scientists and engineers.

In this article, we present a “thought-experiment” to predict the possibility and viability of enhancing the plasticity of metallic glasses, and its strength as well. The main idea is to create a new design of the glassy materials, the granular glass, via spatially patterning heterogeneities. To prove this idea, we used finite element modeling. The extensive work and analysis show that this new approach is not only possible but effective in “engineering” ductility in the materials that are known as “brittle.” We expect this work to stimulate experiments that can turn this idea into reality.

Graphical abstract

Glassy materials do not have ordered atomic structures. As a result, they all appear brittle macroscopically. As a twist, different from other types of glasses such as oxide glasses, metallic glasses possess tremendous ductility in small scales on nanometers and micrometers. Therefore, how to manage the microscopic ductility and extend it to macroscopic scale becomes one of the most challenging engineering as well as scientific problems facing materials scientists and engineers. In this article, we predict the possibility and viability of enhancing the plasticity of metallic glasses, and its strength as well. The main idea is to create a new design of the glassy materials, the granular glass, via spatially patterning heterogeneities. To prove this idea, we used finite element modeling. The extensive work and analysis show that this new approach is not only possible but effective in “engineering” ductility into the materials that are known as “brittle.” We expect this work to stimulate experiments that can turn this idea into reality.

Similar content being viewed by others

Data availability

Data used in this work are available from the authors upon request.

Code availability

The code used in this work is primarily from ABAQUS, which is available commercially.

References

L.G. Sun, G. Wu, Q. Wang, J. Lu, Mater. Today 38, 114 (2020)

C.A. Schuh, T.C. Hufnagel, U. Ramamurty, Acta Mater. 55, 4067 (2007)

J.W. Liu, Q.P. Cao, L.Y. Chen, X.D. Wang, J.Z. Jiang, Acta Mater. 58, 4827 (2010)

W.-H. Wang, C. Dong, C. Shek, Mater. Sci. Eng. R. 44, 45 (2004)

M.H. Lee, K.S. Lee, J. Das, Scr. Mater. 62, 678 (2010)

Y. Zhang, W.H. Wang, A.L. Greer, Nat. Mater. 5, 857 (2006)

C. Suryanarayana, A. Inoue, Bulk Metallic Glasses (CRC Press, New York, 2011)

J. Das, M.B. Tang, W.H. Wang, J. Eckert, Phys. Rev. Lett. 94, 205501 (2005)

K.F. Yao, F. Ruan, Y.Q. Yang, N. Chen, Appl. Phys. Lett. 88, 122106 (2006)

S. Scudino, B. Jerliu, S. Pauly, Scr. Mater. 65, 815 (2011)

H. Choi-Yim, W.L. Johnson, Appl. Phys. Lett. 71(26), 3808 (1997)

C.C. Hays, C.P. Kim, W.L. Johnson, Phys. Rev. Lett. 13(84), 2901 (2000)

D.C. Hofmann, J.Y. Suh, A. Wiest, Nature 451, 1085 (2008)

S.F. Guo, L. Liu, N. Li, Y. Li, Scr. Mater. 62, 329 (2010)

D.H. Kim, W.T. Kim, E.S. Park, N. Mattern, J. Eckert, Prog. Mater. Sci. 58(8), 1103 (2013)

E.S. Park, D.H. Kim, Acta Mater. 54, 2597 (2006)

E.S. Park, J.S. Kyeong, D.H. Kim, Scr. Mater. 57, 49 (2007)

M. Zhao, M. Li, Metals 2, 488 (2012)

Y.W. Wang, M. Li, J.W. Xu, Scr. Mater. 113, 10 (2016)

Y.W. Wang, M. Li, J.W. Xu, Scr. Mater. 135, 41 (2017)

Y.W. Wang, M. Li, J.W. Xu, Scr. Mater. 130, 12 (2017)

H. Gleiter, Acta Mater. 48(1), 1 (2000)

H. Gleiter, Acta Mater. 56, 5875 (2008)

H. Gleiter, Beilstein J. Nanotechnol. 4, 517 (2013)

J.X. Fang, U. Vainio, W. Puff, Nano Lett. 12, 458 (2012)

C. Guo, B. Wu, S. Lan, G. Peng, X. Wang, H. Hahn, H. Gleiter, T. Feng, Mater. Res. Lett. 5, 293 (2017)

H. Gleiter, Prog. Mater. Sci. 33, 223 (1989)

N. Chen, D.V.L. Luzgin, K.F. Yao, J. Alloys Compd. 707, 371 (2017)

H. Gleiter, Th. Schimmel, H. Hahn, Nano Today 9(1), 17 (2014)

M. Zhao, M. Li, Appl. Phys. Lett. 93, 241906 (2008)

Y.F. Gao, Model. Simul. Mater. Sci. Eng. 14, 1329 (2006)

M. Zhao, M. Li, Y.F. Zheng, Philos. Mag. Lett. 91(11), 705 (2011)

J. Yi, W.H. Wang, J.J. Lewandowski, Acta Mater. 87(1), 1 (2015)

Q.K. Li, M. Li, Appl. Phys. Lett. 88, 241903 (2006)

C.Q. Chen, Y.T. Pei, O. Kuzmin, Z.F. Zhang, E. Ma, J.T.M. De Hosson, Phys. Rev. B. 83, 180201 (2011)

X. Wang, F. Jiang, H. Hahn, J. Li, H. Glitter, J. Sunna, J. Fang, Scr. Mater. 98, 40 (2015)

J.J. Marattukalama, V. Pacheco, D. Karlsson, L. Riekehr, J. Lindwall, F. Forsberg, U. Jansson, M. Sahlberg, B. Hjörvarsson, Addit. Manuf. 33, 101124 (2020)

Y. Ivanisenko, C. Kübel, S.H. Nandam, C. Wang, X. Mu, O. Adjaoud, K. Albe, H. Hahn, Adv. Eng. Mater. 20, 1800404 (2018)

S.H. Nandam, Y. Ivanisenko, R. Schwaiger, Z. Sniadecki, X. Mu, D. Wang, R. Chellali, T. Boll, A. Kilmametov, T. Bergfeldt, H. Gleiter, H. Hahn, Acta Mater. 136, 181 (2017)

W. Liu, B.A. Sun, H. Gleiter, S. Lan, Y. Tong, X. Wang, H. Hahn, Y. Yang, J. Kai, C.T. Liu, Nano Lett. 18, 4188 (2018)

X. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, J. Fang, Scr. Mater. 116, 95 (2016)

S.H. Nandam, O. Adjaoud, R. Schwaiger, Y. Mohammed, R. Chellali, D. Wang, K. Albe, H. Hahn, Acta Mater. 193, 252 (2020)

A. Sharma, S.H. Nandam, H.T. Hahn, K.E. Prasad, Front. Mater. 8, 676764 (2021)

M. Ghidelliab, A. Orekhovcde, A. LiBassia, G. Terraneof, P. Djemiab, G. Abadiasg, M. Norddeh, A. Béchéde, N. Gauquelinde, J. Verbeeckde, J.-P. Raskini, D. Schryversde, T. Pardoenc, H. Idriss, Acta Mater. 213, 116955 (2021)

A. Sharma, S.H. Nandam, H. Hahn, K.E. Prasad, Scr. Mater. 191, 17 (2021)

S. Adibi, P.S. Branicio, R. Ballarini, RSC Adv. 6, 13548 (2016)

K. Albe, Y. Ritter, D. Sopu, Mech. Mater. 67, 94 (2013)

D. Şopu, K. Albe, J. Nanotechnol. 6, 537 (2015)

O. Adjaoud, K. Albe, Acta Mater. 145, 322 (2018)

C. Kalcher, O. Adjaoud, J. Rohrer, A. Stukowski, K. Albe, Scr. Mater. 141, 115 (2017)

X. Zhou, C. Chen, Int. J. Plast. 80, 75 (2016)

Z. Sha, P.S. Branicio, H.P. Lee, T.E. Tay, Int. J. Plast. 90, 231 (2017)

Z.D. Sha, P.S. Branicio, Q.X. Pei, Z.S. Liu, H.P. Lee, T.E. Tay, T.J. Wang, Nanoscale 7, 17404 (2015)

Y. Ritter, D. Sopu, H. Gleiter, K. Albe, Acta Mater. 59, 6588 (2011)

D. Şopu, C. Soyarslan, B. Sarac, S. Bargmann, M. Stoica, J. Eckert, Acta Mater. 106, 199 (2016)

O. Adjaoud, K. Albe, Acta Mater. 15, 393 (2019)

S. Yuan, P.S. Branicio, Int. J. Plast. 134, 102845 (2020)

Funding

Y.W.W. is supported by the Fundamental Research Funds for the Central Universities (FRF-TP-20-028A1) and the Fundamental Research Funds for the Central Universities and The Youth Teacher International Exchange & Growth Program (QNXM20210044).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflit of interest

Here, we declare there are no financial and personal relationships with other people or organizations that could inappropriately influence (bias) this work.

Rights and permissions

About this article

Cite this article

Wang, Y., Gleiter, H. & Li, M. From patterning heterogeneity to nanoglass: A new approach to harden and toughen metallic glasses. MRS Bulletin 48, 56–67 (2023). https://doi.org/10.1557/s43577-022-00347-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-022-00347-w