Abstract

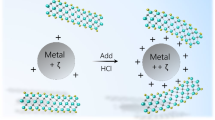

The authors demonstrate that multicomponent metallic alloy nanofoams can be synthesized by the polymeric templating method. The present approach enabled alloy compositions not accessible via commonly used dealloying or co-deposition methods. The authors report the synthesis of a Cu50Ni50 alloy nanofoam using electrospinning polymeric templating, which exhibits distinct polycrystallinity, process-driven segregation, and enhanced mechanical strength over pure Cu nanofoams. Transmission electron microscopy revealed microscopic grain formation and their variable compositions. The processing method is applicable to the synthesis of a wide range of multicomponent metal porous materials, creating new research opportunities for noble alloy foams not available through wet electrochemical routes.

Similar content being viewed by others

References

W. Luc and F. Jiao: Nanoporous metals as electrocatalysts: state-of-the-art, opportunities, and challenges. ACS Catal. 7, 5856 (2017).

J. Biener, A.M. Hodge, J.R. Hayes, C.A. Volkert, L.A. Zepeda-Ruiz, A.V. Hamza, and F.F. Abraham: Size effects on the mechanical behavior of nanoporous Au. Nano Lett. 6, 2379 (2006).

A. Neogi, L. He, and N. Abdolrahim: Atomistic simulations of shock compression of single crystal and core-shell Cu@ Ni nanoporous metals. Jpn J. Appl. Phys. 126, 015901 (2019).

J. Biener, G.W. Nyce, A.M. Hodge, M.M. Biener, A.V. Hamza, and S.A. Maier: Nanoporous plasmonic metamaterials. Adv. Mater. 20, 1211 (2008).

I. McCue, E. Benn, B. Gaskey, and J. Erlebacher: Dealloying and dealloyed materials. Annu. Rev. Mater. Res. 46, 263 (2016).

M. Stratmann and M. Rohwerder: Materials science: a pore view of corrosion. Nature 410, 420 (2001).

J. Erlebacher: An atomistic description of dealloying porosity evolution, the critical potential, and rate-limiting behavior. J. Electrochem. Soc. 151, C614 (2004).

M. Hakamada and M. Mabuchi: Fabrication, microstructure, and properties of nanoporous Pd, Ni, and their alloys by dealloying. Crit. Rev. Solid State Mater. Sci. 38, 262 (2013).

G.G. Li and H. Wang: Dealloyed nanoporous gold catalysts: from macroscopic foams to nanoparticulate architectures. ChemNanoMat 4, 897 (2018).

A. Hodge, R. Doucette, M. Biener, J. Biener, O. Cervantes, and A. Hamza: Ag effects on the elastic modulus values of nanoporous Au foams. J. Mater. Res. 24, 1600 (2009).

C.-E. Kim, R.M. Rahimi, N. Hightower, I. Mastorakos, and D.F. Bahr: Synthesis, microstructure, and mechanical properties of polycrystalline Cu nano-foam. MRS Adv. 3, 469 (2018).

J. Zhang, M.D. Baró, E. Pellicer, and J. Sort: Electrodeposition of magnetic, superhydrophobic, non-stick, two-phase Cu–Ni foam films and their enhanced performance for hydrogen evolution reaction in alkaline water media. Nanoscale 6, 12490 (2014).

A. Greiner and J.H. Wendorff: Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew. Chem. Int. Ed. 46, 5670 (2007).

J. Liu, M.J. Chang, and H.L. Du: Facile preparation of cross-linked porous poly(vinyl alcohol) nanofibers by electrospinning. Mater. Lett. 183, 318 (2016).

B.M. Eick and J.P. Youngblood: SiC nanofibers by pyrolysis of electrospun preceramic polymers. J. Mater. Sci. 44, 160 (2009).

P.J. Spencer and W. Slough: Applied and experimental chemical thermodynamics at high temperatures. High Temp. High Press. 2, 123 (1970).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

D.F. Bahr and D.J. Morris: Nanoindentation: localized probes of mechanical behavior of materials. In Springer Handbook of Experimental Solid Mechanics, ed. W.N. Sharpe (Springer, New York NY, 2008), pp. 389–404.

S. Divinski, J. Ribbe, G. Schmitz, and C. Herzig: Grain boundary diffusion and segregation of Ni in Cu. Acta Mater. 55, 3337 (2007).

E.A. Zen: Validity of “Vegard’s Law” 41(5–6), 523–524 (1956).

A.R. Denton and N.W. Ashcroft: Vegard’s law. Phys. Rev. A 43, 3161 (1991).

J. Erlebacher, M.J. Aziz, A. Karma, N. Dimitrov, and K. Sieradzki: Evolution of nanoporosity in dealloying. Nature 410, 450 (2001).

W. Weisweiler: Kinetic studies of the catalytic graphitizing of glass-like carbon with the aid of nickel. High Temp. High Press. 2, 187 (1970).

M. Ashby: The properties of foams and lattices. Philos. Trans. R. Soc. A 364, 15 (2006).

X. Xiao, H. Yu, H. Jin, M. Wu, Y. Fang, J. Sun, Z. Hu, T. Li, J. Wu, and L. Huang: Salt-templated synthesis of 2D metallic MoN and other nitrides. ACS Nano 11, 2180 (2017).

X. Xiao, H. Song, S. Lin, Y. Zhou, X. Zhan, Z. Hu, Q. Zhang, J. Sun, B. Yang, and T. Li: Scalable salt-templated synthesis of two-dimensional transition metal oxides. Nat. Commun. 7, 1 (2016).

F.J. Burpo, E.A. Nagelli, A.R. Losch, J.K. Bui, G.T. Forcherio, D.R. Baker, J.P. McClure, S.F. Bartolucci, and D.D. Chu: Salt-templated platinum-copper porous macrobeams for ethanol oxidation. Catalysts 9, 662 (2019).

F.J. Burpo, E.A. Nagelli, A.N. Mitropoulos, S.F. Bartolucci, J.P. McClure, D.R. Baker, A.R. Losch, and D.D. Chu: Salt-templated platinum–palladium porous macrobeam synthesis. MRS Commun. 9, 280 (2019).

Acknowledgments

The authors gratefully acknowledge support from the National Science Foundation under Grant No. CMMI 1634772.

Author information

Authors and Affiliations

Corresponding author

Supplementary material

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2020.16

Rights and permissions

About this article

Cite this article

Kim, CE., Rahimi, R.M. & Bahr, D.F. The structure and mechanical properties of Cu50Ni50 alloy nanofoams formed via polymeric templating. MRS Communications 10, 286–291 (2020). https://doi.org/10.1557/mrc.2020.16

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2020.16