Abstract

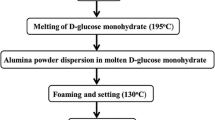

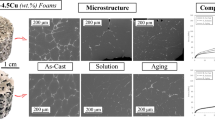

Cordierite foams were prepared by thermo-foaming of alumina–microsilica–talc powder dispersions in molten D-glucose anhydrous followed by reaction sintering at 1400 °C, which exhibited an interconnected cellular morphology and three-dimensional porous cell walls. The cordierite foam had a porosity of up to 96%, and its corresponding thermal conductivity was as low as 0.057 W/(m·K). The foam structures showed a great promise for gas filtration and gas catalytic support. The formation of interconnected cellular morphology, the variations of cell wall thickness, and cell size were explained from the perspective of viscosity and weak points in this paper. The linear shrinkage of cordierite foams having a density of 0.102–0.226 g/cm3 was in the range of 13.0–6.9%. And the compressive strength (0.05–0.28 MPa) was determined by the large cell size (1.1–1.3 mm), ultra-high porosity (91–96%), and characteristic of cordierite.

Similar content being viewed by others

References

D. Kuscer, I. Bantan, M. Hrovat, and B. Malic: The microstructure, coefficient of thermal expansion and flexural strength of cordierite ceramics prepared from alumina with different particle sizes. J. Eur. Ceram. Soc. 37, 739–746 (2017).

I. Janković-Častvan, S. Lazarević, B. Jordović, R. Petrović, D. Tanasković, and D. Janaćković: Electrical properties of cordierite obtained by non-hydrolytic sol–gel method. J. Eur. Ceram. Soc. 27, 3659–3661 (2007).

J. Wu, C. Hu, X. Xu, Y. Zhang, C. Lu, and D. Wang: Preparation and thermal shock resistance of cordierite-spodumene composite ceramics for solar heat transmission pipeline. Ceram. Int. 42, 13547–13554 (2016).

J. Luyten, I. Thijs, W. Vandermeulen, S. Mullens, B. Wallaeys, and R. Mortelmans: Strong ceramic foams from polyurethane templates. Br. Ceram. Trans. 104, 4–8 (2005).

M.J. Matos, S. Dias, F.A.C. Oliveira, and F.A. Costa: Macrostructural changes of polymer replicated open cell cordierite based foams upon sintering. Br. Ceram. Trans. 106, 209–215 (2007).

F.A.C. Oliveira, S. Dias, M. Fátima Vaz, and J.C. Fernandes: Behaviour of open-cell cordierite foams under compression. J. Eur. Ceram. Soc. 26, 179–186 (2006).

F.A.C. Oliveira, S. Dias, M. Fátima Vaz, and J.C. Fernandes: Crushing behaviour of cellular cordierite foams. Mater. Sci. Forum 455–4562, 172–176 (2004).

E.R. Silva, N. Correia, J.M. Silva, F.A.C. Oliveira, F.R. Ribeiro, J.C. Bordado, and M.F. Ribeiro: Manufacture of cordierite foams by direct foaming. Polimery 52, 351–356 (2007).

E.R. Silva, J.M. Silva, F.A.C. Oliveira, F.R. Ribeiro, J.C. Bordado, and M.F. Vaz: Strength improvement of cordierite foams by a dip coating method. Mater. Sci. Forum 587–588, 123–127 (2008).

Y. Sun, J. Zhang, S. Lu, and H. Liu: Preparation of porous cordierite ceramic by gel-casting method. Adv. Appl. Ceram. 116, 1–6 (2007).

S. Akpinar, İ.M. Kuşoğlu, O. Ertugrul, and K. Onel: Microwave assisted sintering of in situ cordierite foam. Ceram. Int. 41, 8605–8613 (2015).

Y. Li, W. Cao, J. Feng, L. Gong, and X. Cheng: Fabrication of cordierite foam ceramics using direct foaming and slip casting method with plaster moulds. Adv. Appl. Ceram. 114, 465–470 (2015).

Y. Li, W. Cao, L. Gong, R. Zhang, and X. Cheng: Properties of highly porous cordierite ceramic obtained by direct foaming and gelcasting method. Ceram.-Silik. 60, 1–10 (2016).

S. Vijayan, P. Wilson, and K. Prabhakaran: Ultra low-density mullite foams by reaction sintering of thermo-foamed alumina-silica powder dispersions in molten sucrose. J. Eur. Ceram. Soc. 37, 1657–1664 (2016).

S. Vijayan, R. Narasimman, C. Prudvi, and K. Prabhakaran: Preparation of alumina foams by the thermo-foaming of powder dispersions in molten sucrose. J. Eur. Ceram. Soc. 34, 425–433 (2014).

E.R. Silva, J.M. Silva, F.A.C. Oliveira, M.F. Vaz, and M.F. Ribeiro: Cordierite foam supports washcoated with zeolite-based catalysts for volatile organic compounds (VOCs) combustion. Mater. Sci. Forum 636–637, 7 (2010).

E.K. Kok, J. Banjuraizah, S.F. Khor, and Z.A. Ahmad: Preparation and characterization of porous cordierite for catalyst support application. Mater. Sci. Forum (2016).

T.Y. Yang, W.Y. Kim, S.Y. Yoon, and H.C. Park: Macroporous silicate ceramics prepared by freeze casting combined with polymer sponge method. J. Phys. Chem. Solids 71, 436–439 (2010).

T.D. Senguttuvan, H.S. Kalsi, S.K. Sharda, and B.K. Das: Sintering behavior of alumina rich cordierite porous ceramics. Mater. Chem. Phys. 67, 146–150 (2001).

S. Vijayan, P. Wilson, and K. Prabhakaran: Porosity and cell size control in alumina foam preparation by thermo-foaming of powder dispersions in molten sucrose. J. Eur. Ceram. Soc. 4, 344–350 (2016).

K. Huang, Y. Li, S. Li, L. Wang, and S. Wang: Effects of microsilica addition on the microstructure and properties of alumina foams. Ceram. Int. 42, 16401–16404 (2016).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51772221 and 51502213) and the Key Program of Natural Science Foundation of Hubei Province of China (Grant No. 2017CFA004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Li, Y., Xiang, R. et al. Fabrication of ultra-high-porosity cordierite foams by the thermo-foaming of powder dispersions in molten D-glucose anhydrous. Journal of Materials Research 34, 1818–1825 (2019). https://doi.org/10.1557/jmr.2019.13

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.13