Abstract

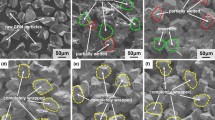

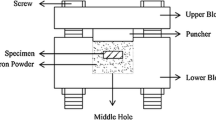

Influence of boron nitride (BN) addition in commercially pure titanium (Cp-Ti) was characterized for their microstructural variation, hardness, and oxidation kinetics. Feedstock powders, Cp-Ti with 3 wt% BN (3BN) and 6 wt% BN (6BN), were prepared by roller mill followed by additive manufacturing using laser engineered net shaping (LENS™). Rate of oxidation was measured from thermogravimetric analysis (TGA) at 1000 °C for 50 h. Average instantaneous parabolic constants (kp) for Cp-Ti, 3BN, and 6BN were 41.2 ± 12.0, 28.6 ± 2.8, and 18.2 ± 9.2 mg2/(cm4 h), respectively. Cp-Ti displayed acicular α-Ti microstructure. After TGA, large equiaxed grains along with TiO2 formation at the grain boundaries were observed, which increased the hardness. With BN addition, plate-like TiN and needle-like TiB secondary phases were also observed. Hardness for Cp-Ti, 3BN, and 6BN were 256.9 ± 7.7, 424.0 ± 33.6, and 548.3 ± 49.7 HV0.2, respectively. Overall, a small addition of BN was effective in improving the oxidation resistance of Cp-Ti.

Similar content being viewed by others

References

J. Dai, J. Zhu, C. Chen, and F. Weng High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J. Alloys Compd. 685, 784–798 (2016).

Z. Huda and P. Edi Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 46, 552–560 (2013).

Y. Zhou, Q.Y. Zhang, J.Q. Liu, X.H. Cui, J.G. Mo, and S.Q. Wang Wear characteristics of a thermally oxidized and vacuum diffusion heat treated coating on Ti–6Al–4V alloy. Wear 344, 9–21 (2015).

S. Wang, Z. Liao, Y. Liu, and W. Liu Influence of thermal oxidation temperature on the microstructural and tribological behavior of Ti6Al4V alloy. Surf. Coating. Technol. 240, 470–477 (2014).

M. Peters, J. Kumpfert, C.H. Ward, and C. LeyensTitanium and Titanium Alloys (Wiley-VCH, Weinheim, 2003).

K. Aniołek The influence of thermal oxidation parameters on the growth of oxide layers on titanium. Vacuum 144, 94–100 (2017).

A. Kanjer, L. Lavisse, V. Optasanu, P. Berger, C. Gorny, P. Peyre, F. Herbst, O. Heintz, N. Geoffroy, T. Montesin, and M.C. Marco de Lucas Effect of laser shock peening on the high temperature oxidation resistance of titanium. Surf. Coating. Technol. 326, 146–155 (2017).

P. Kofstad, K. Hauffe, H. Kjöllesdal, P. Siekevitz, L. Ernster, and E. Diczfalusy Investigation on the oxidation mechanism of titanium. Acta Chem. Scand. 12, 239–266 (1958).

D.K. Das and S.P. Trivedi Microstructure of diffusion aluminide coatings on Ti-base alloy IMI-834 and their cyclic oxidation behaviour at 650 °C. Mater. Sci. Eng., A 367, 225–233 (2004).

A. Ebach-Stahl, C. Eilers, N. Laska, and R. Braun Cyclic oxidation behaviour of the titanium alloys Ti-6242 and Ti-17 with Ti–Al–Cr–Y coatings at 600 and 700 °C in air. Surf. Coat. Technol. 223, 24–31 (2013).

A.K. Lal, S.K. Sinha, P.K. Barhai, K.G.M. Nair, S. Kalavathy, and D.C. Kothari Effect of 60 keV nitrogen ion implantation on oxidation resistance of IMI 834 titanium alloy. Surf. Coating. Technol. 203, 2605–2607 (2009).

L. Raceanu, V. Optasanu, T. Montesin, G. Montay, and M. Francois Shot-peening of pre-oxidized plates of zirconium: Influence of residual stress on oxidation. Oxid. Met. 79, 135–145 (2013).

V. Optasanu, P. Jacquinot, and T. Montesin Influence of the residual stresses induced by shot-peening on the oxidation of Zr plates. Adv. Mater. Res. 996, 912–917 (2014).

T. Gualtieri and A. Bandyopadhyay Additive manufacturing of compositionally gradient metal-ceramic structures: Stainless steel to vanadium carbide. Mater. Des. 139, 419–428 (2017).

T. Gualtieri and A. Bandyopadhyay Niobium carbide compostie coatings on SS304 using laser engineered net shaping (LENS™). Mater. Lett. 189, 89–92 (2017).

K. Stenberg, S. Dittrick, S. Bose, and A. Bandyopadhyay Influence of simultaneous addition of carbon nanotubes and calcium phosphate on wear resistance of 3D Printed Ti6Al4V. J. Mater. Res. 33, 2077–2086 (2018).

H. Sahasrabudhe and A. Bandyopadhyay Additive manufacturing of reactive in situ Zr based ultra-high temperature ceramic composites. J. Miner. Met. Mater. Soc. 68, 822–830 (2016).

Y. Hu, F. Ning, H. Wang, W. Cong, and B. Zhao Laser engineered net shaping of quasi-continuous network microstructural TiB reinforced titanium matrix bulk composites: Microstructure and wear performance. Opt. Laser Technol. 99, 174–183 (2018).

M. Zadra and L. Girardini High-performance, low-cost titanium metal matrix composites. Mater. Sci. Eng., A 608, 155–163 (2014).

Z.H. Ding, Z.H. Ding, B. Yao, L.X. Qiu, S.Z. Bai, X.Y. Guo, Y.F. Xue, W.R. Wang, X.D. Zhou, and W.H. Su Formation of titanium nitride by mechanical milling and isothermal annealing of titanium and boron nitride. J. Alloys Compd. 391, 77–81 (2005).

H. Okamoto and H. BakerASM Handbook: Alloy Phase Diagrams, Vol. 3 (ASM International, Materials Park, OH, 1992).

I. Barin and O. KnackeThermochemical Properties of Inorganic Substances (Springer-Verlag, Berlin Heidelberg, 1973).

K. Panda and K. Ravi Chandran Synthesis of ductile titanium–titanium boride (Ti-TiB) composites with a beta-titanium matrix: The nature of TiB formation and composite properties. Metall. Mater. Trans. A 34, 1371–1385 (2003).

M.M.H. Bhuiyan, L.H. Li, J. Wang, P. Hodgson, and Y. Chen Interfacial reactions between titanium and boron nitride nanotubes. Scr. Mater. 127, 108–112 (2017).

M. Ceramics, S.P. Gordienko, and T.M. Evtushok Reaction of titanium with boron nitride under self-propagating high-temperature synthesis conditions. Powder Metall. Met. Ceram. 40, 58–60 (2001).

K.S.R. Chandran and K.B. Panda Titanium composites with TiB whiskers. Adv. Mater. Process. 160, 59–62 (2002).

B. Heer, H. Sahasrabudhe, A.K. Khanra, and A. Bandyopadhyay Boron nitride-reinforced SS316 composite: Influence of laser processing parameters on microstructure and wear resistance composites. J. Mater. Sci. 52, 10829–10839 (2017).

Y. Zhang, H. Sahasrabudhe, and A. Bandyopadhyay Additive manufacturing of Ti–Si–N ceramic coatings on titanium. Appl. Surf. Sci. 346, 428–437 (2015).

D.O. AlbinaTheory and Experience on Corrosion of Waterwall and Superheater Tubes of Was-to-Energy Facilities (Columbia University, New York, 2005).

P.R. RobergeHandbook of Corrosion Engineering (McGraw-Hill, New York, 2000).

P. Pérez, J.L. González-Carrasco, and P. Adeva Influence of powder particle size on the oxidation behavior of a PM Ni3Al alloy. Oxid. Met. 49, 485–507 (1998).

M.W. Brumm and H.J. Grabke The oxidation behaviour of NiAl-I. Phase transformations in the alumina scale during oxidation of NiAl and NiAl-Cr alloys. Corros. Sci. 33, 1677–1690 (1992).

M. Binnewies and E. MilkeThermochemical Data of Elements and Compounds (Wiley-VCH Verlag GmbH, Weinheim, New York, 2002).

H. Sahasrabudhe, R. Harrison, C. Carpenter, and A. Bandyopadhyay Stainless steel to titanium bimetallic structure using LENS. Addit. Manuf. 5, 1–8 (2015).

V.K. Balla, W. Xue, S. Bose, and A. Bandyopadhyay Functionally graded Co–Cr–Mo coating on Ti–6Al–4V alloy structures. Acta Biomater. 4, 697–706 (2008).

M. Das, K. Bhattacharya, S.A. Dittrick, C. Mandal, V.K. Balla, T.S. Sampath Kumar, A. Bandyopadhyay, and I. Manna In situ synthesized TiB-TiN reinforced Ti6Al4V alloy composite coatings: Microstructure, tribological and in-vitro biocompatibility. J. Mech. Behav. Biomed. Mater. 29, 259–271 (2014).

E. Chikarakara, S. Naher, and D. Brabazon High speed laser surface modification of Ti–6Al–4V. Surf. Coating. Technol. 206, 3223–3229 (2012).

H. Sahasrabudhe, J. Soderlind, and A. Bandyopadhyay Laser processing of in situ TiN/Ti composite coating on titanium. J. Mech. Behav. Biomed. Mater. 53, 239–249 (2016).

W. Xiang, M. Xuliang, L. Xinlin, D. Lihua, and W. Mingjia Effect of boron addition on microstructure and mechanical properties of TiC/Ti6Al4V composites. Mater. Des. 36, 41–46 (2012).

G. Matache, D.M. Stefanescu, C. Puscasu, and E. Alexandrescu Dendritic segregation and arm spacing in directionally solidified CMSX-4 superalloy. Int. J. Cast Met. Res. 29, 303–316 (2016).

H. Attar, S. Ehtemam-Haghighi, D. Kent, X. Wu, and M.S. Dargusch Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng., A 705, 385–393 (2017).

M. Das, V.K. Balla, D. Basu, T.S. Sampath Kumar, and A. Bandyopadhyay Laser processing of in situ synthesized TiB-TiN-reinforced Ti6Al4V alloy coatings. Scr. Mater. 66, 578–581 (2012).

H. Feng, Y. Zhou, D. Jia, Q. Meng, and J. Rao Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB/Ti metal matrix composites. Cryst. Growth Des. 6, 1626–1630 (2006).

B. Kooi, Y. Pei, and J. De Hosson The evolution of microstructure in a laser clad TiB–Ti composite coating. Acta Mater. 51, 831–845 (2003).

K. Ravi Chandran, K. Panda, and S. Sahay TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. J. Miner. Met. Mater. Soc. 56, 42–48 (2004).

L.J. Huang, L. Geng, A.B. Li, F.Y. Yang, and H.X. Peng In situ TiBw/Ti–6Al–4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 60, 996–999 (2009).

N.C. Saha and H.G. Tompkins Titanium nitride oxidation spectroscopy study chemistry: An X-ray photoelectron. J. Appl. Phys. 72, 3072–3079 (1992).

M. Bermingham, S. McDonald, M. Dargusch, and D. StJohn Grain-refinement mechanisms in titanium alloys. J. Mater. Res. 23, 97–104 (2007).

M.J. Bermingham, S.D. McDonald, M.S. Dargusch, and D.H. StJohn The mechanism of grain refinement of titanium by silicon. Scr. Mater. 58, 1050–1053 (2008).

Acknowledgments

Authors would like to acknowledge financial support from the National Science Foundation under the grant number NSF-CMMI 1538851 (PI—Bandyopadhyay) and the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health under Award Number R01 AR067306-01A1. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Avila, J.D., Bandyopadhyay, A. Influence of boron nitride on reinforcement to improve high temperature oxidation resistance of titanium. Journal of Materials Research 34, 1279–1289 (2019). https://doi.org/10.1557/jmr.2019.11

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.11