Abstract

Boron nitride nanotubes (BNNTs) have been utilized to strengthen various engineering materials especially metal matrix composites thanks to their extraordinary high tensile strength, elastic modulus, and failure strain. In this paper, single- and multi-walled BNNTs were therefore used to combine with aluminum (Al) metal matrix. Mechanical characteristics and deformation mechanism of nanocomposites reinforced with long (continuous) and short (discontinuous) BNNTs were then investigated for different loadings including uniaxial tension and compression and different boundary conditions based on molecular dynamics simulations. It was found that long BNNTs remarkably improved tensile mechanical properties of the matrix and effectively enhanced elastic modulus and strength of the nanocomposites by 82% and 79.4%, respectively. They could provide effective barriers to propagation path of dislocations formed inside the matrix. Diameter and wall number of the reinforcement did not leave considerable impacts on the nanocomposite behavior while its atomic fraction remarkably influenced the material response.

Similar content being viewed by others

References

C. Zhi, Y. Bando, C. Tang, and D. Golberg: Boron nitride nanotubes. Mater. Sci. Eng., R 70, 92 (2010).

M. Santosh, P.K. Maiti, and A.K. Sood: Elastic properties of boron nitride nanotubes and their comparison with carbon nanotubes. J. Nanosci. Nanotechnol. 9, 5425 (2009).

A.P. Suryavanshi, M-F. Yu, J. Wen, C. Tang, and Y. Bando: Elastic modulus and resonance behavior of boron nitride nanotubes. Appl. Phys. Lett. 84, 2527 (2004).

N.G. Chopra and A. Zettl: Measurement of the elastic modulus of a multi-wall boron nitride nanotube. Solid State Commun. 105, 297 (1998).

M-L. Liao, Y-C. Wang, S-P. Ju, T-W. Lien, and L-F. Huang: Deformation behaviors of an armchair boron-nitride nanotube under axial tensile strains. J. Appl. Phys. 110, 054310 (2011).

M-L. Liao, T-W. Lian, and S-P. Ju: Tensile and compressive behaviours of a boron nitride nanotube: Temperature effects. Mater. Sci. Forum 700, 125 (2012).

D. Golberg, Y. Bando, C.C. Tang, and C.Y. Zhi: Boron nitride nanotubes. Adv. Mater. 19, 2413 (2007).

D. Lahiri, A. Hadjikhani, C. Zhang, T. Xing, L.H. Li, Y. Chen, and A. Agarwal: Boron nitride nanotubes reinforced aluminum composites prepared by spark plasma sintering: Microstructure, mechanical properties and deformation behavior. Mater. Sci. Eng., A 574, 149 (2013).

Y. Chen, J. Zou, S.J. Campbell, and G.L. Caer: Boron nitride nanotubes: Pronounced resistance to oxidation. Appl. Phys. Lett. 84, 2430 (2004).

C. Zhi, Y. Bando, C. Tang, S. Honda, H. Kuwahara, and D. Golberg: Boron nitride nanotubes/polystyrene composites. J. Mater. Res. 21, 2794 (2006).

C. Zhi, Y. Bando, T. Terao, C. Tang, H. Kuwahara, and D. Golberg: Towards thermoconductive, electrically insulating polymeric composites with boron nitride nanotubes as fillers. Adv. Funct. Mater. 19, 1857 (2009).

C. Zhi, Y. Bando, C. Tang, H. Kuwahara, and D. Golberg: Grafting boron nitride nanotubes: From polymers to amorphous and graphitic carbon. J. Phys. Chem. C 111, 1230 (2007).

J. Ravichandran, A.G. Manoj, J. Liu, I. Manna, and D.L. Carroll: A novel polymer nanotube composite for photovoltaic packaging applications. Nanotechnology 19, 085712 (2008).

C.Y. Zhi, Y. Bando, C.C. Tang, Q. Huang, and D. Golberg: Boron nitride nanotubes: Functionalization and composites. J. Mater. Chem. 18, 3900 (2008).

C. Zhi, L. Zhang, Y. Bando, T. Terao, C. Tang, H. Kuwahara, and D. Golberg: New crystalline phase induced by boron nitride nanotubes in polyaniline. J. Phys. Chem. C 112, 17592 (2008).

C.Y. Zhi, Y. Bando, W.L. Wang, C.C. Tang, H. Kuwahara, and D. Golberg: Mechanical and thermal properties of polymethyl methacrylate–BN nanotube composites. J. Nanomater. 2008, 642036 (2008).

D. Lahiri, F. Rouzaud, T. Richard, A.K. Keshri, S.R. Bakshi, L. Kos, and A. Agarwal: Boron nitride nanotube reinforced polylactide–polycaprolactone copolymer composite: Mechanical properties and cytocompatibility with osteoblasts and macrophages in vitro. Acta Biomater. 6, 3524 (2010).

C. Zhi, Y. Bando, C. Tang, S. Honda, K. Sato, H. Kuwahara, and D. Golberg: Characteristics of boron nitride nanotube–polyaniline composites. Angew. Chem., Int. Ed. 44, 7929 (2005).

N.P. Bansal, J.B. Hurst, and S.R. Choi: Boron nitride nanotubes-reinforced glass composites. J. Am. Ceram. Soc. 89, 388 (2006).

Q. Huang, Y. Bando, X. Xu, T. Nishimura, C. Zhi, C. Tang, F. Xu, L. Gao, and D. Golberg: Enhancing superplasticity of engineering ceramics by introducing BN nanotubes. Nanotechnology 18, 485706 (2007).

M. Griebel and J. Hamaekers: Molecular dynamics simulations of boron–nitride nanotubes embedded in amorphous Si–B–N. Comput. Mater. Sci. 39, 502 (2007).

D. Lahiri, V. Singh, A.P. Benaduce, S. Seal, L. Kos, and A. Agarwal: Boron nitride nanotube reinforced hydroxyapatite composite: Mechanical and tribological performance and in vitro biocompatibility to osteoblasts. J. Mech. Behav. Biomed. Mater. 4, 44 (2011).

P. Tatarko, S. Grasso, H. Porwal, Z. Chlup, R. Saggar, I. Dlouhy, and M.J. Reece: Boron nitride nanotubes as a reinforcement for brittle matrices. J. Eur. Ceram. Soc. 34, 3339 (2014).

S. Trivedi, S.C. Sharma, and S.P. Harsha: Evaluations of young’s modulus of boron nitride nanotube reinforced nano-composites. Procedia Mater. Sci. 6, 1899 (2014).

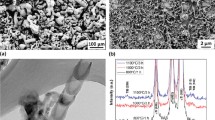

Y. Xue, B. Jiang, L. Bourgeois, P. Dai, M. Mitome, C. Zhang, M. Yamaguchi, A. Matveev, C. Tang, Y. Bando, K. Tsuchiya, and D. Golberg: Aluminum matrix composites reinforced with multi-walled boron nitride nanotubes fabricated by a high-pressure torsion technique. Mater. Des. 88, 451 (2015).

M. Yamaguchi, A. Pakdel, C. Zhi, Y. Bando, D-M. Tang, K. Faerstein, D. Shtansky, and D. Golberg: Utilization of multiwalled boron nitride nanotubes for the reinforcement of lightweight aluminum ribbons. Nanoscale Res. Lett. 8, 3 (2013).

M. Yamaguchi, D-M. Tang, C. Zhi, Y. Bando, D. Shtansky, and D. Golberg: Synthesis, structural analysis and in situ transmission electron microscopy mechanical tests on individual aluminum matrix/boron nitride nanotube nanohybrids. Acta Mater. 60, 6213 (2012).

M.S. Daw and M.I. Baskes: Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1984).

M.I. Mendelev, D.J. Srolovitz, G.J. Ackland, and S. Han: Effect of Fe segregation on the migration of a non-symmetric sigma-5 tilt grain boundary in Al. J. Mater. Res. 20, 208 (2005).

J. Tersoff: Modeling solid-state chemistry: Interatomic potentials for mnlticomponent systems. Phys. Rev. B 39, 5566 (1989).

S. Arcidiacono, J.H. Walther, D. Poulikakos, D. Passerone, and P. Koumoutsakos: Solidification of gold nanoparticles in carbon nanotubes. Phys. Rev. Lett. 94, 105502 (2005).

H.Y. Song and X.W. Zha: Influence of nickel coating on the interfacial bonding characteristics of carbon nanotube–aluminum composites. Comput. Mater. Sci. 49, 899 (2010).

X. Song, Z. Gan, S. Liu, H. Yan, and Q. Lv: Computational study of thermocompression bonding of carbon nanotubes to metallic substrates. J. Appl. Phys. 106, 104308 (2009).

F. Banhart: Interactions between metals and carbon nanotubes: At the interface between old and new materials. Nanoscale 1, 201 (2009).

B.K. Choi, G.H. Yoon, and S. Lee: Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading. Composites, Part B 91, 119 (2016).

Y. Kim, J. Lee, M.S. Yeom, J.W. Shin, H. Kim, Y. Cui, J.W. Kysar, J. Hone, Y. Jung, S. Jeon, and S.M. Han: Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat. Commun. 4, 2114 (2013).

R. Rezaei, M. Shariati, H. Tavakoli-Anbaran, and C. Deng: Mechanical characteristics of CNT-reinforced metallic glass nanocomposites by molecular dynamics simulations. Comput. Mater. Sci. 119, 19 (2016).

R. Rezaei, C. Deng, M. Shariati, and H. Tavakoli-Anbaran: The ductility and toughness improvement in metallic glass through the dual effects of graphene interface. J. Mater. Res. 32, 392 (2017).

R. Rezaei, C. Deng, H. Tavakoli-Anbaran, and M. Shariati: Deformation twinning-mediated pseudoelasticity in metal–graphene nanolayered membrane. Philos. Mag. Lett. 96, 322 (2016).

V.P. Filippova, S.A. Kunavin, and M.S. Pugachev: Calculation of the parameters of the Lennard-Jones potential for pairs of identical atoms based on the properties of solid substances. Inorg. Mater. Appl. Res. 6, 1 (2015).

J.W. Kang and H.J. Hwang: Comparison of C60 encapsulations into carbon and boron nitride nanotubes. J. Phys.: Condens. Matter 16, 3901 (2004).

E. Mohammadpour and M. Awang: Nonlinear finite-element modeling of graphene and singleand multi-walled carbon nanotubes under axial tension. Appl. Phys. A 106, 581 (2012).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 17, 1 (1995).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool modelling. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Rezaei, R., Shariati, M. & Tavakoli-Anbaran, H. Mechanical characteristics and deformation mechanism of boron nitride nanotube reinforced metal matrix nanocomposite based on molecular dynamics simulations. Journal of Materials Research 33, 1733–1741 (2018). https://doi.org/10.1557/jmr.2018.93

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.93