Abstract

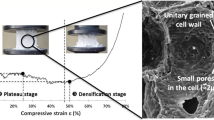

Alumina gel-cast foams were manufactured in a broad total porosity range (43–86%) by using agarose or ovalbumin as gelling agents. The foams were examined in terms of microstructural, permeability, and mechanical properties. For the achieved open porosity level (19–85%), the mean cell size (19–375 µm), and mean window size (8–77 µm) of the alumina foams manufactured using ovalbumin were slightly wider than those obtained using agarose (34–262 µm and 18–33 µm, respectively). By using different contents of agarose (0.3–1 wt%) or albumin (5 wt%) and solids (30–45.9 wt%), it was possible to vary the foaming yield from 1.6 to 4.4 and produce bodies with a very wide permeability level that included several classes of porous ceramics. Darcian (k1) and non-Darcian (k2) permeability coefficients displayed values in the range 3.2 × 10−18 to 4.3 × 10−9 m2 and 1.8 × 10−18 to 6.5 × 10−5 m respectively. Compressive strength of bodies was dependent upon the porosity level, with a variation of 8.5–149.7 MPa.

Similar content being viewed by others

References

M. Scheffler and P. Colombo, eds.: Cellular Ceramics: Structure, Manufacture, Properties and Applications (Wiley-VCH, Weinheim, 2005).

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed. (Cambridge University Press, Cambridge, United Kingdom, 1999); pp. 15–50.

R. Zhang, R. He, W. Zhou, Y. Wang, and D. Fang: Design and fabrication of porous ZrO2/(ZrO2 + Ni) sandwich ceramics with low thermal conductivity and high strength. Mater. Des. 14, 1–6 (2014).

K. Schwartzwalder and A.V. Somers: Method of making porous ceramics articles. U.S. Patent No. 3 090 094, 1963.

P. Sepulveda and J.G.P. Binner: Processing of cellular ceramics by foaming and in situ polymerisation of organic monomers. J. Eur. Ceram. Soc. 19 (12), 2059–2066 (1999).

S. Komarneni, L. Pach, and R. Pidugu: Porous-alumina ceramics using bohemite and rice flour. Mater. Res. Soc. Symp. Proc. 371, 285–290 (1995).

P. Colombo and J.R. Hellmann: Ceramic foams from preceramic polymers. Mater. Res. Innovations 6, 260–272 (2002).

T. Fujiu, G.L. Messing, and W. Huebner: Processing and properties of cellular silica synthesized by foaming sol–gels. J. Am. Ceram. Soc. 73, 85–90 (1990).

D.J. Green: Fabrication and mechanical properties of lightweight ceramics produced by sintering of hollow spheres. J. Am. Ceram. Soc. 68, 403–409 (1985).

M.D.M. Innocentini, P. Sepulveda, V.R. Salvini, and V.C. Pandolfelli: Permeability and structure of cellular ceramics: A comparison between two preparation techniques. J. Am. Ceram. Soc. 81 (12), 3349–3352 (1998).

R. Brezny and D.J. Green: Fracture behavior of open-cell ceramics. J. Am. Ceram. Soc. 72 (7), 1145–1152 (1989).

F.S. Ortega, P. Sepulveda, and V.C. Pandolfelli: Monomer systems for the gelcasting of foams. J. Eur. Ceram. Soc. 22, 1395–1401 (2002).

M. Szafran, A. Szudarska, and P. Bednarek: New low-toxic water-soluble monomers for gelcasting of ceramic powders. Adv. Sci. Technol. 62, 163–168 (2010).

A. Szudarska, T. Mizerski, and M. Szafran: Galactose monoacrylate as a new monomer in gelcasting process. Arch. Metall. Mater. 56, 1211–1215 (2011).

S. Dhara, M. Pradhan, and P. Bhargava: Nature inspired novel processing routes for ceramic foams. Adv. Appl. Ceram. 104 (1), 9–21 (2005).

S. Dhara and P. Bhargava: A simple direct casting route to ceramic foams. J. Am. Ceram. Soc. 86 (10), 1645–1650 (2003).

A.F. Lemos and J.M.F. Ferreira: The valence of egg white for designing smart porous biomaterials: As foaming and consolidation agent. Key Eng. Mater. 254–256, 1045–1050 (2004).

I. Garrn, C. Reetz, N. Brandes, J.W. Kroh, and H. Schubert: Clot-forming: The use of proteins as binders for producing ceramic foams. J. Eur. Ceram. Soc. 24, 579–587 (2004).

K. Prabhakaran, N.M. Gokhale, S.C. Sharma, and R. Lal: A novel process for low-density alumina foams. J. Am. Ceram. Soc. 88, 2600–2603 (2005).

R. Mouazer, I. Thijs, S. Mullens, and J. Luyten: SiC foams produced by gelcasting: Synthesis and characterization. Adv. Eng. Mater. 6, 340–343 (2004).

M. Potoczek: Gelcasting of alumina foams using agarose solutions. Ceram. Int. 34, 661–667 (2008).

M. Potoczek: Hydroxyapatite foams produced by gelcasting using agarose. Mater. Lett. 62, 1055–1057 (2008).

A. Cosijns, C. Vervaet, J. Luyten, S. Mullens, F. Siepmann, L. Van Hoorebeke, B. Masschaele, V. Cnudde, and J.P. Remon: Porous hydroxyapatite tablets as carriers for low-dosed drugs. Eur. J. Pharm. Biopharm. 67, 498–506 (2006).

H. Ghomi, M.H. Fathi, and H. Edris: Effect of the composition of hydroxyapatite/bioactive glass nanocomposite foams on their bioactivity and mechanical properties. Mater. Res. Bull. 47, 3523–3532 (2012).

I. Santacruz and R. Moreno: Preparation of cordierite materials with tailored porosity by gelcasting with polysaccharides. Int. J. Appl. Ceram. Technol. 5, 74–83 (2008).

M. Potoczek, E. Guzi de Moraes, and P. Colombo: Ti2AlC foams produced by gelcasting. J. Eur. Ceram. Soc. 35, 2445–2452 (2015).

L. Yin, X. Zhou, J. Yu, H. Wang, S. Zhao, Z. Luo, and B. Yang: New consolidation process inspired from making steamed bread to prepare Si3N4 foams by protein foaming method. J. Eur. Ceram. Soc. 33, 1387–1392 (2013).

L. Stipniece, I. Narkevica, M. Sokolova, J. Locs, and J. Ozolins: Novel scaffolds based on hydroxyapatite/poly(vinyl alcohol) nanocomposite coated porous TiO2 ceramics for bone tissue engineering. Ceram. Int. 42, 1530–1537 (2016).

F. Akhtar, L. Andersson, S. Ogunwumi, N. Hedin, and L. Bergström: Structuring adsorbents and catalysts by processing of porous powders. J. Eur. Ceram. Soc. 34, 1643–1666 (2014).

C. Tallon, M. Yates, R. Moreno, and M.I. Nieto: Porosity of freeze-dried γ-Al2O3 powders. Ceram. Int. 33, 1165–1169 (2007).

J. Binner, H. Chang, and R. Higginson: Processing of ceramic–metal interpenetrating composites. J. Eur. Ceram. Soc. 29, 837–842 (2009).

J. Ligoda-Chmiel, M. Potoczek, and R.E. Śliwa: Mechanical properties of alumina foam/tri-functional epoxy resin composites with an interpenetrating network structure. Arch. Metall. Mater. 60, 2757–2762 (2015).

M.D.M. Innocentini, J.R. Coury, M. Fukushima, and P. Colombo: High-efficiency aerosol filters based on silicon carbide foams coated with ceramic nanowires. Sep. Purif. Technol. 152, 180–191 (2015).

C. Vakifahmetoglu, D. Zeydanli, M.D.M. Innocentini, F.S. Ribeiro, P.R.O. Lasso, and G.D. Soraru: Gradient-hierarchic-aligned porosity SiOC ceramics. Sci. Rep. 7, 41049 (2017).

M.D.M. Innocentini, W.S. Chacon, R.F. Caldato, G.P. Rocha, and G.L. Adabo: Microstructural, physical, and fluid dynamic assessment of spinel-based and phosphate-bonded investments for dental applications. Int. J. Appl. Ceram. Technol. 52, 18362–18372 (2013).

S. Barg, M.D.M. Innocentini, R.V. Meloni, W.S. Chacon, H. Wang, D. Koch, and G. Grathwohl: Physical and high-temperature permeation features of double-layered cellular filtering membranes prepared via freeze casting of emulsified powder suspensions. J. Membr. Sci. 383, 35–43 (2011).

M.D.M. Innocentini, R.K. Faleiros, R. Pisani, Jr., I. Thijs, J. Luyten, and S. Mullens: Permeability of porous gelcast scaffolds for bone tissue engineering. J. Porous Mater. 17, 615–627 (2010).

M.D.M. Innocentini, V.P. Rodrigues, R.C.O. Romano, R.G. Pileggi, G.M. Silva, and J.R. Coury: Permeability optimization and performance evaluation of hot aerosol filters made using foam incorporated alumina suspension. J. Hazard. Mater. 162, 212–221 (2008).

M.D.M. Innocentini, P. Sepulveda, and F.S. Ortega: Permeability. In Cellular Ceramics: Structure, Manufacture, Properties and Applications, M. Scheffler and P. Colombo, eds. (Wiley-VCH, Weinheim, 2005) pp. 313–341.

M.D.M. Innocentini, A.R.F. Pardo, V.R. Salvini, and V.C. Pandolfelli: How accurate is Darcy’s law for refractories. Am. Ceram. Soc. Bull. 78 (11), 64–68 (1999).

M.D.M. Innocentini, A.R.F. Pardo, V.R. Salvini, and V.C. Pandolfelli: Assessment of Forchheimer’s equation to predict the permeability of ceramic foams. J. Am. Ceram. Soc. 82 (7), 1945–1948 (1999).

M.D.M. Innocentini, E.H. Tanabe, M.L. Aguiar, and J.R. Coury: Filtration of gases at high pressures: Permeation behavior of fiber-based media used for natural gas cleaning. Chem. Eng. Sci. 74, 38–48 (2012).

D. Ruth and D.H. Ma: On the derivation of the Forchheimer equation by means of the averaging theorem. Transp. Porous Media 7, 255–264 (1992).

D. Hlushkou and U. Tallarek: Transition from creeping via viscous-inertial to turbulent flow in fixed beds. J. Chromatogr. A 1126, 70–85 (2006).

Z. Zeng and R. Grigg: A criterion for non-Darcy flow in porous media. Transp. Porous Media 63, 57–69 (2006).

S. Ergun: Flow through packed columns. Chem. Eng. Prog. 48 (2), 89–94 (1952).

L. Biasetto, P. Colombo, M.D.M. Innocentini, and S. Mullens: Gas permeability of microcellular ceramic foams. Ind. Eng. Chem. Res. 46, 3366–3372 (2007).

K. Okada, T. Isobe, K-i. Katsumata, Y. Kameshima, A. Nakajima, and K.J.D. MacKenzie: Porous ceramics mimicking nature—Preparation and properties of microstructures with unidirectionally oriented pores. Sci. Technol. Adv. Mater. 12 (6), 1–11 (2011).

ACKNOWLEDGMENTS

The work has been financially supported by the Faculty of Chemistry of Rzeszów University of Technology (U-594/DS) and by CNPq (Brazilian National Council for Scientific and Technological Development) under the project 303962/2015-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Mello Innocentini, M.D., Rasteira, V.D., Potoczek, M. et al. Physical, fluid dynamic and mechanical properties of alumina gel-cast foams manufactured using agarose or ovalbumin as gelling agents. Journal of Materials Research 32, 2810–2818 (2017). https://doi.org/10.1557/jmr.2017.263

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.263