Abstract

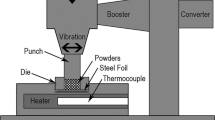

Boron carbide (B4C) powder was consolidated at 45 MPa by Spark Plasma Sintering (SPS) for 20 min from 1450 to 2000 °C. The density of the B4C reached 99.6% at 2000 °C. A continuum model was applied to describe the densification mechanism of B4C powder under SPS conditions. The shrinkage rate was sensitive to particle size and temperature. The effect of porosity on thermal diffusion was significant, especially for small particle sizes. It appears that there is Joule heating, discharge, and electromagnetic field involved during the SPS of B4C. The current can enhance the sintering process, and it can obviously reduce the creep activation energy.

Similar content being viewed by others

References

F. Thevenot: A review on boron carbide. Key Eng. Mater. 56/57, 59 (1991).

R.R. Ridgway: Boron carbide: A new crystalline abrasive and wear resisting product. Trans. Am. Electrochem. Soc. 66, 117 (1934).

H.K. Clark and J.L. Hoard: The crystal structure of boron carbide. J. Am. Chem. Soc. 65(11), 2115 (1943).

G.H. Tang, X.H. Zhang, and C.L. Chen: A comprehensive review on boron carbide. Materials Review 4, 69 (1994).

F. Wu and J. Lu: Applications and the properties of boron carbide ceramic material. Journal of Wuyi University 16, 45 (2002).

L.Z. Pei, H.N. Xiao, B.J. Zhu, and W. Tan: Latest development of boron carbide powder and diphase ceramics. Rare Met. Cem. Carbides 32, 46 (2004).

K.W. Bai, Y.L. Wang, and J.F. Yang: The influence of hot pressing parameters on the microstructures and mechanical properties of boron carbide. Journal of Xi’an Jiaotong University 28, 73 (1994).

B. Mu, H. Zhang, and L. Tang: Influence of the preparation technology on the properties of boron carbide. Powder Metall. Technol. 25, 275 (2007).

R.G. Lange, Z.A. Munir, and J.B. Holt: Sintering kinetics of pure and doped boron carbide. Mater. Sci. Res. 13, 311 (1980).

V. Skorokhod, M.D. Vlajic, and V.D. Krstic: Mechanical properties of pressureless sintered boron carbide containing TiB2 phase. J. Mater. Sci. Lett. 15, 1337 (1996).

L.S. Sigl: Processing and mechanical properties of boron carbide sintered with TiC. J. Eur. Ceram. Soc. 18, 1521 (1998).

L.S. Wang: Special Ceramic, 2nd ed. (Central South Univ. press, Changsha, 2005); p. 186.

X.Y. Zhou: Low temperature sintering technology of boron carbide and its influencing factors. Liaoning Chem. Ind. 40, 291 (2011).

Z.A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi: The effect of electric field on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 41, 763 (2006).

R. Chaim: Densification mechanisms in spark plasma sintering of monocrystalline ceramics. Mater. Sci. Eng., A 443, 25 (2007).

P. Badica, H. Borodianska, S. Xie, T. Zhao, and D. Demirskyi: Toughness control of boron carbide obtained by spark plasma sintering in nitrogen atmosphere. Ceram. Int. 40, 3053 (2014).

S. Hayun, S. Kalabukhov, V. Ezersky, M.P. Dariel, and N. Frage: Microstructural characterization of spark plasma sintered boron carbide ceramics. Ceram. Int. 36, 451 (2010).

X. Li, D. Jiang, J. Zhang, Q. Lin, Z. Chen, and Z. Huang: Densification behavior and related phenomena of spark plasma sintered boron carbide. Ceram. Int. 40, 4359 (2014).

B.M. Moshtaghioun, D. Gómez-García, S.D. Bernardi-Martín, A. Domínguez-Rodríguez, and A. Monshi: Effect of spark plasma sintering parameters on microstructure and room-temperature hardness and toughness of fine-grained boron carbide (B4C). J. Eur. Ceram. Soc. 33, 361 (2013).

C. Xu, K. Flodström, and S. Esmaeilzadeh: Low temperature densification of B4C ceramics with CaF2/Y2O3 additives. Int. J. Refract. Met. Hard Mater. 35, 311 (2012).

K. Sairam, J.K. Sonber, T.S.R.C. Murthy, C. Subramanian, and R.K. Fotedar: Influence of spark plasma sintering parameters on densification and mechanical properties of boron carbide. Int. J. Refract. Met. Hard Mater. 42, 185 (2014).

E.A. Olevsky: Impact of thermal diffusion on densification during SPS. J. Am. Ceram. Soc. 92, S122 (2009).

G. Bernard-Grainger and C. Guizard: Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification. Acta Mater. 55, 3493 (2007).

E.A. Olevsky and L. Froyen: Constitutive modeling of sparking-plasma sintering of conductive materials. Scr. Mater. 55, 1175 (2006).

E.A. Olevsky: Consolidation enhancement in spark-plasma sintering: Impact of high heating rates. J. Appl. Phys. 102, 114913 (2007).

H.B. Wu, F.H. Zeng, and T.C. Yuan: Wettability of 2519Al on B4C at 1000–1250 °C and mechanical properties of infiltrated B4C–2519Al composites. Ceram. Int. 40, 2073 (2014).

E.A. Olevsky and A. Molinari: Instability of sintering of porous bodies. Int. J. Plast. 16, 1 (2000).

E.A. Olevsky and A. Molinari: Kinetics and stability in compressive and tensile loading of porous bodies. Mech. Mater. 38, 340 (2006).

R.L. Coble and W.D. Kingery: Effect of porosity on physical properties of sintered alumina. J. Am. Ceram. Soc. 39, 377 (1956).

J.C. Maxwell: A treatise on electricity and magnetism. In Thermal Conductivity of Solids, J.E. Parrott and A.D. Stuckes, eds. (Pion Lid, London, 1975).

S.V. Konovalikhin and V.I. Ponomarev: Carbon in boron carbide: The crystal structure of B11.4C3.6. Russ. J. Inorg. Chem. 54, 197 (2009).

V. Paris, N. Frage, M.P. Dariel, and E. Zaretsky: The spall strength of silicon carbide and boron carbide ceramics processed by spark plasma sintering. Int. J. Impact. Eng. 37, 1092 (2010).

T.D. Beaudet, J.R. Smith, and J.W. Adams: Surface energy and relaxation in boron carbide ($10⋏r 11$) from first principles. Solid State Commun. 219, 43 (2015).

E. Friedland, N.G.V.D. Berg, J.B. Malherbe, J.J. Hancke, and J. Barry: Diffusion of fission products through silicon carbide. In International Topical Meeting on Nuclear Research Applications and Utilization of Accelerators (International Atomic Energy Agency, Vienna, 2009); p. 8.

M.S. Koval’Chenko, Y.G. Tkachenko, L.F. Ochkas, D.Z. Yurchenko, and V.B. Vinokurov: Densification kinetics of boron carbide in hot pressing. Powder Metall. Met. Ceram. 26, 881 (1987).

Y. Zeng, J.W. Feng, Y.F. Zhang, and C.X. Ding: Relationship between properties and microstructure of plasma sprayed boron carbide coating. J. Inorg. Mater. 15, 137 (2000).

L.S. Wang: The thermal conductivity and thermal expensing coefficient for hot-pressed boron carbide. J. Cent. South Univ. Technol. 34, 111 (2003).

F. Deng: Preparation of Submicron Boron Carbide by Mechanical Alloying (Dalian University of technology, China, 2005).

M. Salvador, J.M. Perlado, A. Mattoni, F. Bernardini, and L. Colombo: Defect energetics of β-SiC using a new tight-binding molecular dynamics model. J. Nucl. Mater. s329–333, 1219 (2004).

E. Rauls: Annealing Mechanisms of Point Defects in Silicon Carbide. Ph.D. thesis (English), Theoretical Physics, Department of Physics, Faculty of Science, University of Paderborn, Germany, 2003.

E.V. Aleksandrova, A.M. Ilyina, E.G. Grigoryev, and E.A. Olevsky: Contribution of electric current into densification kinetics during spark plasma sintering of conductive powder. J. Am. Ceram. Soc. 98, 3509 (2015).

D.M. Zhang: Study on Mechanism of Pulse Electric Current Sintering of Ceramic Materials (Wuhan University of Technology, Wuhan, 2002); pp. 11–35.

Z. Shen, M. Johnsson, Z. Zhao, and M. Nygren: Spark plasma Sintering of alumina. J. Am. Ceram. Soc. 85, 1921 (2002).

ACKNOWLEDGMENTS

This work is supported by the National Natural Science Foundation of China (Grant No. 51301210), supported by State Key Laboratory of Powder Metallurgy of Central South University and State Key Laboratory of New Ceramic and Fine Processing of Tsinghua University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Ja., Zeng, F., Zou, Z. et al. Continuum modeling of B4C densification during Spark Plasma Sintering. Journal of Materials Research 32, 3425–3433 (2017). https://doi.org/10.1557/jmr.2017.205

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.205