Abstract

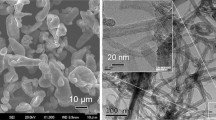

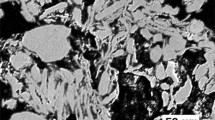

By using high purity aluminum powders and multi-walled carbon nanotubes (MWCNTs) as raw materials, MWCNTs/Al composites were fabricated with ball milling, followed by cold pressing, vacuum sintering, and hot extrusion. It was found that when the sintering temperature was 863 K, MWCNTs/Al composite sintered for 4 h showed good comprehensive properties, and its tensile strength and elongation reached to 156 MPa and 21%, respectively. The comprehensive mechanical properties of the composites became better with raising sintering temperature when the sintering time was 4 h. When the sintering temperature raised to 923 K, the tensile strength of the composite reached to 167 MPa which is three times more than that of annealed high purity aluminum, mainly due to the higher density and better interface bonding resulted from higher sintering temperature. CNTs’ pulling out were observed obviously in the fractured surfaces, and load transfer may be the main strengthening mechanism.

Similar content being viewed by others

References

Z. Wang, R.T. Qu, S. Scudino, B.A. Sun, K.G. Prashanth, D.V. Louzguine-Luzgin, M.W. Chen, Z.F. Zhang, and J. Eckert: Hybrid nanostructured aluminum alloy with super-high strength. NPG Asia Mater. 7 (12), e229 (2015).

S. Bakshi, D. Lahiri, and A. Agarwal: Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 55 (1), 41 (2010).

L. Teng, C.J. Li, Q. Yuan, Q.X. Zhang, Y. Xi, C.H. Li, R. Bao, and X.K. Zhu: Progress of carbon nanotubes reinforced copper matrix composites. Mater. Rev. 28 (7), 16 (2014).

A. Agarwal, S.R. Bakshi, and D. Lahiri: Carbon Nanotubes Reinforced Metal Matrix Composites (CRC Press, New York, 2010).

T. Laha, Y. Chen, D. Lahiri, and A. Agarwal: Tensile properties of carbon nanotube reinforced aluminum nanocomposite fabricated by plasma spray forming. Composites, Part A 40 (5), 589 (2009).

S. Bal and S.S. Samal: Carbon nanotube reinforced polymer composites—A state of the art. Bull. Mater. Sci. 30 (4), 379 (2007).

J.P. Salvetat, J.M. Bonard, N.H. Thomson, A.J. Kulik, L. Forró, W. Benoit, and L. Zuppiroli: Mechanical properties of carbon nanotubes. Appl. Phys. A. 69 (3), 255 (1999).

S. Iijima, C. Brabec, A. Maiti, and J. Bernholc: Structural flexibility of carbon nanotubes. J. Chem. Phys. 104 (5), 2089 (1996).

P.M. Ajayan and J.M. Tour: Materials science—Nanotube composites. Nature 447 (7148), 1066 (2007).

A.D. Moghadam, E. Omrani, P.L. Menezes, and P.K. Rohatgi: Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Composites, Part B 77, 402 (2015).

H. Kwon, G.G. Lee, S.G. Kim, B.W. Lee, W.C. Seo, and M. Leparoux: Mechanical properties of nanodiamond and multi-walled carbon nanotubes dual-reinforced aluminum matrix composite materials. Mater. Sci. Eng., A 632, 72 (2015).

J.G. Park, H.K. Dong, and Y.H. Lee: Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 95, 690 (2015).

C.R. Bradbury, J.K. Gomon, L. Kollo, H. Kwon, and M. Leparoux: Hardness of multi wall carbon nanotubes reinforced aluminium matrix composites. J. Alloys Compd. 585 (3), 362 (2014).

V. Trinh Pham, H.T. Bui, B.T. Tran, V.T. Nguyen, D.Q. Le, X.T. Than, V.C. Nguyen, D.P. Doan, and N.M. Phan: The effect of sintering temperature on the mechanical properties of a Cu/CNT nanocomposite prepared via a powder metallurgy method. Adv. Nat. Sci.: Nanosci. Nanotechnol. 2 (1), 015006 (2011).

X.N. Hao, H.P. Zhang, R.X. Zheng, Y.T. Zhang, K. Ameyama, and M.A. Chao-Li: Effect of mechanical alloying time and rotation speed on evolution of CNTs/Al-2024 composite powders. Trans. Nonferrous Met. Soc. China 24 (7), 2380 (2014).

R. Pérez-Bustamante, I. Estrada-Guel, W. Antúnez-Flores, M. Miki-Yoshida, P.J. Ferreira, and R. Martínez-Sánchez: Novel Al-matrix nanocomposites reinforced with multi-walled carbon nanotubes. J. Alloys Compd. 450 (1–2), 323 (2008).

Z.Y. Liu, S.J. Xu, B.L. Xiao, P. Xue, W.G. Wang, and Z.Y. Ma: Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Composites, Part A 43 (12), 2161 (2012).

P. Chandran, T. Sirimuvva, N. Nayan, A.K. Shukla, S.V.S.N. Murty, S.L. Pramod, S.C. Sharma, and S.R. Bakshi: Effect of carbon nanotube dispersion on mechanical properties of aluminum–silicon alloy matrix composites. J. Mater. Eng. Perform. 23 (3), 1028 (2014).

M. Mazaheri, S.A. Hassanzadeh-Tabrizi, and S.K. Sadrnezhaad: Hot pressing of nanocrystalline zinc oxide compacts: Densification and grain growth during sintering. Ceram. Int. 35 (3), 991 (2008).

R. Pérez-Bustamante, I. Estrada-Guel, P. Amézaga-Madrid, M. Miki-Yoshida, J.M. Herrera-Ramírez, and R. Martínez-Sánchez: Microstructural characterization of Al-MWCNT composites produced by mechanical milling and hot extrusion. Mater. Sci. Eng., A 495 (2), 399 (2010).

I. Sridhar and K.R. Narayanan: Processing and characterization of MWCNT reinforced aluminum matrix composites. J. Mater. Sci. 44 (7), 1750 (2009).

L. Ci, Z. Ryu, N.Y. Jin-Phillipp, and M. Rühle: Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta Mater. 54 (20), 5367 (2006).

R. Pérez-Bustamante, C.D. Gómez-Esparza, I. Estrada-Guel, M. Miki-Yoshida, L. Licea-Jiménez, S.A. Pérez-García, and R. Martínez-Sánchez: Microstructural and mechanical characterization of Al–MWCNT composites produced by mechanical milling. Mater. Sci. Eng., A 502 (1–2), 159 (2009).

Z. Li, L. Jiang, G. Fan, Y. Xu, D. Zhang, Z. Chen, and S. Humphries: High volume fraction and uniform dispersion of carbon nanotubes in aluminium powders. Micro Nano Lett. 5 (6), 379 (2010).

Z. Wang, K. Georgarakis, K.S. Nakayama, Y. Li, A.A. Tsarkov, G. Xie, D. Dudina, D.V. Louzguine-Luzgin, and A.R. Yavari: Microstructure and mechanical behavior of metallic glass fiber-reinforced Al alloy matrix composites. Sci. Rep. 6, 24384 (2016).

F. Housaer, F. Beclin, M. Touzin, D. Tingaud, A. Legris, and A. Addad: Interfacial characterization in carbon nanotube reinforced aluminum matrix composites. Mater. Charact. 110, 94 (2015).

X. Zhu, Y-G. Zhao, M. Wu, H-Y. Wang, and Q-C. Jiang: Fabrication of 2014 aluminum matrix composites reinforced with untreated and carboxyl-functionalized carbon nanotubes. J. Alloys Compd. 674, 145 (2016).

H.J. Choi, J.H. Shin, and D.H. Bae: The effect of milling conditions on microstructures and mechanical properties of Al/MWCNT composites. Composites, Part A 43 (7), 1061 (2012).

ACKNOWLEDGMENT

The authors acknowledge professor Ming Xie at Kunming Institution of Precious Metals in China for technical assistance and Dr. Benxin Wu at Purdue University in the United States for helpful discussions. Additional financial supports provided by the Natural Science Foundation of Yunnan Provincial Science and Technology Department (grant 2014FC001 and 2011FB021), Natural Science Foundation of Kunming university of Science and Technology (grant KKSY201551036), Undergraduate Innovation and Entrepreneurship Training Program of Kunming university of Science and Technology (grant 201510674071), and National Natural Science Foundation of China (grant 51361017) are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, C., Liu, X., Yi, J. et al. Effects of sintering parameters on the microstructure and mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Journal of Materials Research 31, 3757–3765 (2016). https://doi.org/10.1557/jmr.2016.436

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.436